These specialized drinking vessels, often personalized or bearing distinctive insignias, serve primarily as receptacles for hot beverages. They offer a tangible and reusable alternative to disposable cups, frequently found in office environments or personal collections. A common application involves the consumption of coffee or tea during work hours.

Their significance extends beyond mere functionality. They contribute to a reduction in single-use waste and can serve as promotional items for businesses or commemorative keepsakes. Their durability and potential for customization provide lasting value and recognition. The history of such items traces back to the broader development of ceramic and porcelain production, evolving from simple utilitarian objects to often highly decorated and personalized items.

This article will further explore the characteristics, advantages, and applications of these beverage containers, examining their role in sustainability, marketing, and personal expression. Subsequent sections will delve into material composition, manufacturing processes, and best practices for care and maintenance.

Optimizing the Use of Dedicated Beverage Containers

The following are recommended practices to maximize the utility and longevity of specialized coffee mugs:

Tip 1: Material Selection. Consider the material composition. Ceramic offers heat retention, while stainless steel provides durability and resistance to breakage. Evaluate the intended use environment and choose accordingly.

Tip 2: Proper Cleaning Procedures. Implement appropriate cleaning protocols. Avoid abrasive cleaners on decorated surfaces and ensure thorough rinsing to prevent residue buildup that may affect beverage flavor.

Tip 3: Temperature Considerations. Be mindful of temperature extremes. Avoid sudden temperature changes, especially with ceramic mugs, as this can lead to cracking or shattering.

Tip 4: Safe Handling Practices. Practice safe handling techniques. Use caution when filling or carrying hot beverages to prevent spills or burns. Ensure handles are securely attached before use.

Tip 5: Storage Optimization. Optimize storage practices. Store the mugs in a manner that prevents chipping, scratching, or other damage. Consider using shelving or designated storage areas.

Tip 6: Avoiding Microwaving Decorated Mugs. Exercise caution when microwaving decorated mugs. Metallic paints or accents can cause sparking or damage to both the mug and the microwave.

These practices contribute to extended product lifespan, enhanced user experience, and mitigation of potential hazards. Implementing these guidelines will ensure optimal performance and maintain the integrity of the dedicated beverage containers.

The concluding section will present a summary of the key points discussed and offer considerations for future applications and advancements in the design and utilization of these items.

1. Material Durability

The longevity and utility of coffee mugs are intrinsically linked to material durability. The choice of material directly impacts the mug’s resistance to physical damage, thermal shock, and chemical degradation, influencing its lifespan and suitability for repeated use. Failure to select a durable material results in premature breakage, chipping, or cracking, necessitating replacement and increasing overall costs. For instance, mugs crafted from lower-quality ceramics are susceptible to shattering when exposed to sudden temperature fluctuations, a common occurrence when pouring hot coffee into a cold mug. In contrast, stainless steel mugs exhibit greater resistance to impact and temperature changes, offering superior durability in demanding environments.

The significance of material durability extends beyond mere resistance to breakage. Durable materials often exhibit greater resistance to staining and odor absorption, maintaining the aesthetic appeal and hygienic qualities of the mug over time. Furthermore, materials with high durability are more likely to withstand repeated cleaning cycles, including dishwashing, without exhibiting signs of wear or degradation. This is exemplified by porcelain mugs, which, while more prone to breakage than stainless steel, offer exceptional stain resistance and can withstand numerous dishwasher cycles without significant discoloration. The material also affects the type of personalization methods. For example, ceramic mugs support a wide range of printing or paint methods, while metal might need more durable methods like laser etching.

In summary, material durability is a critical factor in determining the value proposition. Consideration of material properties is essential to optimize lifespan, performance, and user satisfaction. While initial cost may be a factor, the long-term benefits of selecting a durable material, including reduced replacement costs and improved overall user experience, outweigh the initial investment. The optimal material choice depends on the intended use environment and desired balance between durability, aesthetic appeal, and cost.

2. Heat Retention

Heat retention in coffee mugs directly influences the sustained temperature of the contained beverage. The primary function of a coffee mug is to hold and present the drink; however, its effectiveness is significantly enhanced by its capacity to maintain the beverage at a palatable temperature for an extended period. The following facets explore the complexities of heat retention in relation to these specialized drinking vessels.

- Material Composition and Thermal Conductivity

The material from which a mug is constructed dictates its thermal conductivity, which is a measure of its ability to conduct heat. Materials with low thermal conductivity, such as ceramic or double-walled stainless steel, impede heat transfer, thus maintaining the beverage’s temperature for a longer duration. Conversely, materials with high thermal conductivity, like aluminum, facilitate rapid heat loss, leading to a quicker temperature decline. The selection of material is therefore paramount in optimizing heat retention. For example, a porcelain mug, though aesthetically pleasing, may lose heat faster than a vacuum-insulated stainless-steel mug due to differences in their thermal conductivity.

- Insulation Techniques and Design

Beyond material selection, design elements significantly contribute to heat retention. Double-walled construction, creating a vacuum or air gap between the inner and outer layers, serves as an effective insulator, minimizing heat transfer through conduction. Vacuum-insulated mugs, in particular, are highly effective at maintaining beverage temperature. The inclusion of a lid also reduces heat loss through convection and evaporation. For instance, a mug with a tight-fitting lid significantly outperforms an open mug in maintaining the temperature of the coffee over a period of time. A good design will also avoid any thermal bridge between the outside and the inside of the mug.

- Surface Area and Heat Dissipation

The surface area of a mug influences the rate of heat dissipation. A mug with a larger surface area exposes more of the beverage to the surrounding environment, resulting in a faster rate of heat loss. This is particularly relevant when comparing different mug sizes and shapes. Mugs with a smaller surface area to volume ratio tend to retain heat better. For example, a taller, narrower mug will generally maintain beverage temperature better than a shorter, wider mug of the same volume and material.

- Environmental Factors and External Temperature

External environmental conditions affect the rate of heat loss from a coffee mug. In colder environments, the temperature differential between the beverage and the surroundings is greater, leading to faster heat transfer. Conversely, in warmer environments, the rate of heat loss is reduced. The presence of drafts or wind can also accelerate heat loss through convection. Therefore, the effectiveness of heat retention is contingent on the ambient temperature. The same mug may perform adequately in a warm office setting but inadequately outdoors in winter. Therefore, vacuum-insulated tumblers become the preferred option.

The interplay between material, design, surface area, and environmental factors collectively determines the heat retention capability of a coffee mug. Maximizing heat retention through careful consideration of these elements enhances the user experience, ensuring that the beverage remains at a palatable temperature for a prolonged duration. This consideration is particularly important in professional settings or during outdoor activities, where sustained beverage temperature is desirable or necessary.

3. Design Aesthetics

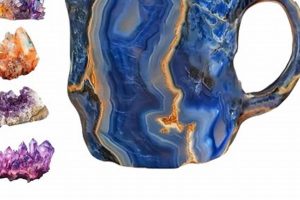

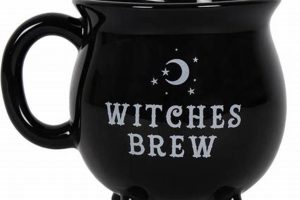

The visual appeal of these specialized beverage containers significantly influences user perception and brand recognition. Design aesthetics, encompassing form, color, and decorative elements, plays a crucial role in shaping the consumer’s interaction and overall satisfaction. The visual characteristics create an emotional link between the user and the product, influencing purchasing decisions and long-term usage.

- Form and Silhouette

The shape of the mug contributes significantly to its aesthetic appeal and usability. Variations in form, from cylindrical to conical and more organic shapes, impact the mug’s visual profile and ergonomic properties. A well-designed silhouette should balance visual appeal with functional considerations, such as ease of holding and stability. For example, a mug with a wide base is less prone to tipping, while a contoured shape may provide a more comfortable grip. Furthermore, different shapes evoke diverse aesthetic associations; a sleek, minimalist form may convey modernity, while a more ornate shape may suggest tradition.

- Color Palette and Visual Harmony

The selection of colors and their arrangement directly influence the mug’s visual impact and brand identity. Color palettes may range from monochromatic schemes to vibrant, contrasting combinations. The use of color can evoke specific emotions or associations, influencing the perceived value and desirability. Furthermore, the harmonious integration of colors enhances the overall aesthetic coherence. For instance, a mug with muted, earthy tones may convey a sense of warmth and naturalness, while a mug with bold, contrasting colors may project energy and excitement. The color should also be resistant to fading and discoloration over time.

- Decorative Elements and Surface Texture

The addition of decorative elements, such as patterns, illustrations, or textures, enhances the visual complexity and tactile experience of the mug. Decorative elements can be applied through various techniques, including printing, embossing, and engraving. The choice of decorative elements can reflect the brand’s identity or convey a specific message. For example, a mug featuring intricate floral patterns may appeal to a different demographic than a mug with a minimalist geometric design. The surface texture, whether smooth, matte, or textured, also contributes to the overall sensory experience and visual interest.

- Branding and Logo Integration

The effective integration of branding elements, such as logos and slogans, is crucial for promoting brand recognition and reinforcing brand identity. Branding elements should be incorporated seamlessly into the overall design, enhancing rather than detracting from the aesthetic appeal. The placement, size, and style of the branding elements should be carefully considered to maintain visual harmony and clarity. For example, a subtly embossed logo may convey a sense of sophistication, while a boldly printed logo may emphasize brand visibility. Consistency in branding across different product lines strengthens brand recognition and reinforces brand messaging.

In summary, design aesthetics plays a vital role in determining the user’s perception and engagement. By carefully considering form, color, decorative elements, and branding integration, producers can craft visually compelling mugs that not only enhance the drinking experience but also strengthen brand identity and drive consumer appeal. The interplay between these aspects is critical to develop a compelling and attractive coffee mug.

4. Ergonomic Handle

The ergonomic handle represents a critical design element in specialized beverage containers, directly influencing user comfort, safety, and overall satisfaction. Its significance stems from its role as the primary interface between the user and the heated contents of the vessel. An inadequately designed handle can lead to discomfort, hand fatigue, or even burns, detracting from the intended function and compromising the user experience. Consequently, the handle’s shape, size, material, and positioning are meticulously considered during the design and manufacturing processes. For example, handles designed with a contour that matches the natural curvature of the hand minimize strain and promote a secure grip. The selection of a non-heat-conducting material, such as polypropylene, mitigates the risk of burns when handling hot liquids.

The practical application of ergonomic principles to handle design extends beyond basic comfort. Handles are engineered to distribute weight evenly, reducing stress on specific pressure points. The handle’s size is carefully calibrated to accommodate a range of hand sizes, ensuring universal usability. Textured surfaces or strategically placed grooves enhance grip stability, minimizing the risk of slippage, particularly when handling a full mug. Furthermore, the handle’s orientation and distance from the mug’s body are optimized to prevent contact between the hand and the heated surface. Cases of poorly designed handles, often found on mass-produced or inexpensive mugs, frequently result in user complaints related to discomfort, instability, and the potential for burns. Such instances underscore the importance of prioritizing ergonomic considerations in the design and manufacturing process. Often handles can be positioned at a certain angle to reduce the need to unnaturally twist the wrist, which can result in strains.

In conclusion, the ergonomic handle is an indispensable component. Its design directly impacts user comfort, safety, and the overall usability. Prioritizing ergonomic principles in handle design is essential for mitigating risks, enhancing user satisfaction, and optimizing the functional value of these specialized drinking vessels. Challenges remain in balancing ergonomic considerations with aesthetic appeal and cost-effectiveness, but continued innovation in materials and manufacturing techniques offer opportunities to overcome these hurdles. A mug cannot reach its full potential of utility if the ergonomic of a handle is bad, so companies must be aware of this and make it a priority.

5. Capacity Volume

The capacity volume of coffee mugs directly influences their practicality and suitability for various consumption patterns. The volume, measured in ounces or milliliters, dictates the quantity of liquid a mug can hold, thereby determining the serving size it accommodates. Mugs with smaller capacity volumes, typically ranging from 8 to 12 ounces, are suitable for single servings of coffee or tea, aligning with standard brewing practices. Larger capacity volumes, exceeding 16 ounces, cater to individuals who prefer larger servings or extended consumption periods. The selection of an appropriate capacity volume is thus intrinsically linked to individual preferences and usage scenarios. For instance, an office environment may favor mugs with moderate capacity volumes to accommodate standard coffee maker settings, while a home setting may see greater variability depending on personal preferences.

Furthermore, capacity volume impacts the mug’s thermal properties. A larger volume of liquid retains heat for a longer duration compared to a smaller volume, given similar material properties. This becomes particularly relevant in colder environments or during prolonged periods of consumption. However, larger capacity mugs may also present challenges in terms of handling and stability, particularly if the design does not adequately account for the increased weight when full. The shape and dimensions of the mug must be proportionally balanced to ensure a comfortable and secure grip, preventing spills and promoting safe handling. Real-world examples include insulated travel mugs with high capacity for commuters and smaller, more manageable mugs for desk use.

In summary, capacity volume is a defining characteristic. Its influence extends beyond mere quantity, impacting the practical suitability, thermal performance, and handling characteristics. An informed consideration of these factors is essential to optimize the functionality and user experience. The trend towards personalized and customizable items suggests that consumers are increasingly discerning about choosing mugs that align with their specific needs and preferences, underscoring the importance of offering a range of capacity options. Understanding this relationship is crucial for both manufacturers and consumers to maximize satisfaction and utility.

6. Personalization Options

The capability to customize beverage containers offers significant value, augmenting their inherent utility with elements of individual expression and brand identity. Customization capabilities enhance appeal. These options transform commonplace items into personalized artifacts, strengthening user connection and promoting brand loyalty.

- Direct Printing and Decals

Direct printing techniques, including screen printing and digital printing, apply images, text, or logos directly onto the mug surface. Decals, pre-printed designs adhered to the mug and then heat-cured, offer another common customization method. These methods accommodate various design complexities, ranging from simple monograms to elaborate graphics. An example is the application of a company logo to mugs used for employee gifts, or the printing of family photos as sentimental keepsakes. Direct printing and decals enable mass customization, providing cost-effective personalization for large quantities.

- Engraving and Etching

Engraving and etching techniques utilize lasers or mechanical tools to create permanent markings on the mug surface. These methods produce detailed, tactile designs that resist fading or wear. Engraving is frequently applied to stainless steel mugs, while etching is commonly used on glass or ceramic. Examples include personalized names or dates etched onto commemorative mugs or intricate patterns engraved onto collectible items. The permanence of engraving and etching lends a sense of enduring quality and sophistication.

- Color and Finish Customization

Beyond graphic elements, mugs can be personalized through the selection of specific colors and finishes. Manufacturers offer a wide range of color options, allowing customers to match their mugs to their personal preferences or brand guidelines. Different finishes, such as matte, glossy, or textured coatings, further enhance the aesthetic appeal. An example is a corporate client choosing specific Pantone colors for mugs that reflect their brand identity. Color and finish customization provides subtle yet impactful personalization, creating mugs that resonate with individual tastes and brand values.

- Shape and Handle Variations

Less commonly, but increasingly available, are options to customize the mug’s shape or handle design. While limited by manufacturing constraints, certain producers offer variations in mug profiles or handle styles. These customizations cater to specific ergonomic or aesthetic preferences. A possible example includes a limited run of mugs with uniquely shaped handles as a promotional item or for collectors. Customizing these features elevates personalization beyond surface decoration, creating mugs tailored to individual requirements and tastes.

These personalization options elevate these vessels beyond mere receptacles for hot beverages. They create opportunities for self-expression, brand reinforcement, and the creation of meaningful gifts. The integration of these customizable elements allows for increased consumer engagement and promotes a stronger connection with these everyday objects.

Frequently Asked Questions Regarding Victor Coffee Mugs

The following addresses common inquiries and misconceptions pertaining to these specialized beverage containers, providing clear, factual information for informed decision-making.

Question 1: What materials are typically used in the manufacturing of Victor Coffee Mugs, and how do these materials affect their performance?

Victor Coffee Mugs are commonly manufactured using ceramic, porcelain, stainless steel, or glass. Ceramic and porcelain offer good heat retention and aesthetic appeal but can be prone to breakage. Stainless steel provides durability and resistance to impact, while glass offers visual transparency but may be susceptible to thermal shock. The material selection directly impacts the mug’s heat retention, durability, and overall lifespan.

Question 2: Are Victor Coffee Mugs dishwasher and microwave safe?

The dishwasher and microwave safety of these mugs depend on the material and decoration. Mugs with metallic accents or coatings are generally not microwave safe. While most ceramic and stainless steel mugs are dishwasher safe, repeated exposure to high temperatures and harsh detergents may degrade decorative elements. Consult the manufacturer’s instructions for specific care guidelines.

Question 3: How does the shape and design of these specialized mugs influence heat retention and user comfort?

The shape and design significantly impact heat retention and user comfort. Mugs with a narrower opening and thicker walls tend to retain heat longer. Ergonomically designed handles enhance grip comfort and reduce the risk of spills. The overall weight and balance of the mug also contribute to ease of use.

Question 4: What are the common methods for personalizing Victor Coffee Mugs, and how do these methods affect the mug’s durability?

Common personalization methods include screen printing, digital printing, engraving, and applying decals. Screen printing and digital printing are cost-effective for large quantities, but the designs may fade over time. Engraving offers a more permanent solution, while decals can be susceptible to peeling or scratching. The chosen method should be compatible with the mug material to ensure durability.

Question 5: What measures should be taken to ensure the longevity and proper care of Victor Coffee Mugs?

To prolong the lifespan of these mugs, avoid sudden temperature changes, use non-abrasive cleaners, and promptly address stains or residues. Hand washing is recommended for mugs with delicate decorations. Proper storage, avoiding stacking that can cause chipping or scratching, also contributes to longevity.

Question 6: Are there any specific regulations or certifications that Victor Coffee Mugs must adhere to, particularly concerning food safety?

These products intended for food contact must adhere to relevant food safety regulations, such as those established by the Food and Drug Administration (FDA) in the United States and similar regulatory bodies in other countries. These regulations address the use of safe materials and limit the leaching of harmful substances into beverages. Certifications, such as those indicating compliance with BPA-free standards, provide assurance of product safety.

These answers provide a baseline understanding of frequently encountered inquiries concerning these specialized coffee mugs. Further research and consultation with product specifications are recommended for specific use-cases.

The next section will delve into the market trends and future directions in the design and production of these beverage containers.

Concluding Remarks on Victor Coffee Mugs

This exposition has examined various facets of victor coffee mugs, ranging from material composition and heat retention to design aesthetics and personalization options. Key points encompass the importance of selecting durable materials for longevity, optimizing ergonomic design for user comfort, and offering diverse personalization options to cater to individual preferences. The analysis has underscored the critical role of capacity volume in determining suitability for various consumption patterns and the necessity of adhering to food safety regulations to ensure consumer well-being.

The continuing demand for these specialized beverage containers necessitates a commitment to innovation in materials, manufacturing processes, and design principles. As consumer awareness of sustainability and ergonomic considerations increases, so too must the efforts of manufacturers to meet these evolving expectations. Therefore, a focus on quality, safety, and responsible production practices remains paramount. The industry’s ongoing response will dictate the future trajectory of this product category and its impact on daily life.

![Best 8 Ounce Travel Coffee Mug [Portable Size!] Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Best 8 Ounce Travel Coffee Mug [Portable Size!] | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://deacoffee.com/wp-content/uploads/2025/06/th-2621-300x200.jpg)

![Best Campfire Coffee Mugs [Outdoor Gear] Reviews Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Best Campfire Coffee Mugs [Outdoor Gear] Reviews | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://deacoffee.com/wp-content/uploads/2025/06/th-2033-300x200.jpg)