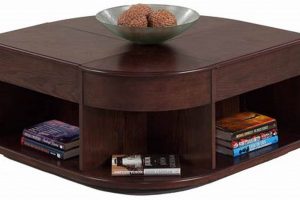

A piece of furniture featuring a flat surface supported by posts shaped through a lathe, this table serves as a focal point in living spaces. The supporting structures, crafted on a rotating machine, exhibit decorative contours and symmetrical designs. These tables are commonly used for placing beverages, books, or decorative items.

These tables offer aesthetic appeal and functional utility to interior design. The sculpted supports contribute to a sense of elegance and craftsmanship, blending traditional artistry with contemporary living. Historically, these tables represent a continuation of woodworking techniques dating back centuries, demonstrating enduring artistry in furniture construction.

The following sections will delve into the specific styles, materials, and considerations involved in selecting and maintaining a table of this type, providing valuable information for both consumers and furniture enthusiasts.

The following guidelines offer insight into choosing a table of this style, considering factors ranging from structural integrity to aesthetic compatibility within a given living space.

Tip 1: Assess Material Durability. Hardwoods such as maple, oak, or walnut offer superior longevity and resistance to wear compared to softer woods. Verify the type of wood used in the table’s construction to ensure suitability for long-term use.

Tip 2: Evaluate Structural Stability. Inspect the joinery connecting the sculpted supports to the tabletop. Dovetail joints and mortise-and-tenon joints offer enhanced stability compared to weaker connection methods, ensuring structural integrity.

Tip 3: Consider Scale and Proportion. Measure the dimensions of the intended space and select a piece of furniture that complements the room’s size. A disproportionately large unit will overwhelm a small area, while an undersized one may appear insignificant.

Tip 4: Analyze the Style Compatibility. Ensure that the aesthetic of the sculpted supports aligns with the existing decor. Ornate designs are well-suited for traditional interiors, while simpler, cleaner lines integrate more readily with modern settings.

Tip 5: Inspect the Finish Quality. Examine the surface finish for imperfections such as uneven coating or scratches. A well-applied finish protects the wood and enhances its aesthetic appeal.

Tip 6: Determine Practical Functionality. Consider the intended use of the table. If frequent use is anticipated, select a table with a robust surface finish and sturdy support structure to withstand daily wear and tear.

Careful consideration of these factors will facilitate a well-informed selection process, ensuring a piece of furniture that provides lasting aesthetic and functional value.

The subsequent section will address the proper care and maintenance protocols to preserve the integrity and appearance of this piece of furniture for years to come.

1. Wood Selection

The selection of wood for a piece of furniture directly influences its durability, aesthetic characteristics, and overall value. In the specific case of a table with lathe-shaped supports, the chosen material dictates the precision and complexity of the design that can be achieved. Hardwoods, such as maple, oak, and walnut, offer superior strength, allowing for intricate detailing in the turned legs without compromising structural integrity. Conversely, using a softer wood, such as pine, may limit the design possibilities and increase the risk of damage during the turning process and subsequent use. Consider, for example, a table constructed from walnut; its inherent grain patterns and rich color enhance the visual appeal of the turned supports, creating a piece of furniture valued for its craftsmanship and elegance.

The type of wood selected also impacts the longevity of the furniture. Hardwoods are resistant to dents, scratches, and warping, ensuring that the piece retains its form and aesthetic appeal over time. Softwoods, while potentially more cost-effective, are more susceptible to damage and may require more frequent repair or replacement. Furthermore, the wood species affects the finishing process. Some woods accept stains and finishes more readily than others, allowing for a wider range of customization options to match specific interior design preferences. The moisture content of the wood before turning is vital, to prevent warping or cracking in the turning process and in final product.

Ultimately, the choice of wood is a critical determinant of the quality and longevity of a turned-leg table. The selection process requires careful consideration of the wood’s strength, grain pattern, workability, and finishing characteristics. Prioritizing high-quality hardwoods ensures a finished product that is both aesthetically pleasing and structurally sound, representing a worthwhile investment in lasting furniture.

2. Turning Style

The aesthetic character of a table with sculpted legs is substantially influenced by the turning style employed in shaping the supporting structures. Turning style, in this context, refers to the specific design and contours imparted to the wood as it is shaped on a lathe. Variations in turning style directly affect the visual impact of the furniture piece. For example, a simple, clean turning style, characterized by straight lines and minimal ornamentation, will impart a contemporary or minimalist aesthetic. Conversely, a more ornate turning style, featuring intricate curves, beads, and coves, will evoke a traditional or Victorian sensibility. The chosen style directly determines the furniture’s compatibility with diverse interior design schemes. A poorly chosen style can disrupt the harmony of a room, while a well-considered style can enhance its overall visual appeal.

Turning style also influences the perceived craftsmanship and value of the table. Highly skilled turners can execute complex designs that showcase their artistry and attention to detail. These intricate designs often require more time and expertise, resulting in a higher-priced piece of furniture. Mass-produced tables with simplified turning styles may be more affordable but lack the unique character and perceived quality of hand-turned designs. Consider the impact of a spiral turning style; the creation of consistent, flowing spirals along the leg requires significant skill and specialized tools, adding to the uniqueness and potential cost of the item.

In summary, turning style is a critical element in defining the aesthetic and value of these tables. Careful consideration of the turning style is essential for ensuring that the finished product aligns with the desired aesthetic, complements the intended interior design, and reflects an appropriate level of craftsmanship. Challenges may arise in sourcing skilled turners capable of executing complex designs or in balancing the cost of labor-intensive turning styles with budget constraints. Understanding the interplay between turning style and the overall design of the table is vital for informed decision-making.

3. Tabletop Shape

The form of the surface on a table with sculpted supports exerts a significant influence on its functionality and aesthetic integration within a room. The tabletop shape, a primary determinant of the piece’s utility, dictates how it serves as a functional surface and affects its visual harmony with surrounding elements. For example, a circular top promotes conversation and accessibility from all sides, fitting well within social seating arrangements. Conversely, a rectangular top offers a greater surface area for display or work, making it suitable for larger spaces or tasks requiring more surface. The table’s silhouette, defined by the tabletop shape, directly impacts its contribution to the overall design scheme.

The choice of shape often reflects both practical considerations and stylistic preferences. A square top might suit a smaller space, providing a compact surface area while maintaining geometric balance. An oval shape can soften the lines of a room, offering a compromise between the angularity of a rectangle and the roundness of a circle. The combination of the tabletop shape and the design of the sculpted supports is crucial; a rustic, farmhouse-style turned leg may pair well with a reclaimed wood rectangular top, while a sleek, modern turning may complement a glass or metal circular top. These pairings illustrate the intentionality behind selecting a shape that harmonizes with the supporting structure and the overall design vision.

Ultimately, the tabletop shape is an integral component of these tables, shaping both its function and aesthetic contribution. Selecting an appropriate shape demands a careful assessment of the intended purpose, spatial constraints, and desired aesthetic outcome. Overlooking this element can result in a piece that feels discordant or functionally inadequate. Awareness of the impact of tabletop shape ensures a cohesive and harmonious addition to any living space, enhancing its usability and visual appeal.

4. Finish Durability

The longevity and aesthetic preservation of tables with lathe-shaped supports are inextricably linked to the durability of the applied finish. This protective layer shields the underlying wood from environmental stressors and daily wear, directly impacting the furniture’s lifespan and visual appeal. A robust finish maintains the integrity of the wooden structure and preserves its aesthetic character.

- Resistance to Abrasion

A durable finish offers resistance against scratches, scuffs, and abrasions resulting from regular use. For instance, a polyurethane finish creates a hard, protective layer that withstands the repeated placement of objects on the tabletop. Conversely, a weak finish, like a thin coat of varnish, is prone to scratching, diminishing the table’s appearance and requiring frequent refinishing.

- Protection Against Moisture

Moisture resistance is crucial to prevent water damage, warping, and staining of the wooden structure. A catalyzed conversion varnish, for example, creates a waterproof barrier, protecting the wood from spills and humidity. Inadequate protection can lead to irreversible damage, necessitating costly repairs or replacement of the furniture.

- UV Light Resistance

Exposure to ultraviolet (UV) light can cause fading and discoloration of the wood and finish over time. Finishes with UV inhibitors, such as certain acrylic lacquers, mitigate this effect, preserving the original color and tone of the wood. Without adequate UV protection, the table may develop an uneven, faded appearance, reducing its aesthetic value.

- Chemical Resistance

A durable finish resists damage from common household chemicals, such as cleaning agents and solvents. Epoxy finishes, known for their chemical resistance, protect the wood from staining and degradation caused by spills. A susceptible finish can be marred by chemical exposure, resulting in unsightly blemishes and potential structural damage.

These facets of finish durability converge to determine the long-term performance and aesthetic appeal of these tables. Selecting a finish that addresses these factors is paramount to safeguarding the investment and ensuring the furniture remains a valued element of the interior environment.

5. Structural Integrity

Structural integrity, the ability of a structure to withstand applied loads without failure, is of paramount importance in the context of a table with lathe-shaped supports. The successful performance of this furniture relies on the robust construction and design of each component, particularly the supports and their connection to the tabletop.

- Wood Selection and Grain Orientation

The type of wood chosen directly influences the table’s ability to bear weight and resist deformation. Hardwoods such as maple, oak, and walnut offer greater strength and resistance to bending compared to softwoods. Furthermore, the orientation of the wood grain within the supports is critical. Aligning the grain along the longitudinal axis of the turned legs maximizes their load-bearing capacity. For example, legs turned from quarter-sawn wood exhibit enhanced stability and resistance to warping, ensuring long-term structural soundness.

- Joinery Techniques

The methods used to connect the lathe-shaped supports to the tabletop significantly impact the table’s overall stability. Strong, well-executed joinery prevents wobbling, sagging, and eventual collapse. Mortise-and-tenon joints, dovetail joints, and properly executed dowel joints offer superior strength compared to weaker connection methods, such as simple screws or nails. A mortise-and-tenon joint, where the tenon is precisely fitted to the mortise, creates a mechanical interlock that distributes weight evenly and prevents racking.

- Leg Geometry and Bracing

The design of the supports, including their thickness, taper, and curvature, influences their ability to withstand compression and bending forces. Thicker legs provide greater resistance to buckling under load. Tapering the legs strategically can optimize strength-to-weight ratio. The addition of bracing elements, such as aprons or stretchers, further enhances the table’s stability by distributing weight and preventing lateral movement. A table with slender, unsupported legs is inherently less stable than one with thicker, braced supports.

- Finish Application and Wood Stabilization

The finish applied to the table not only enhances its aesthetic appeal but also contributes to its structural integrity by sealing the wood and preventing moisture absorption. Moisture fluctuations can cause wood to swell and shrink, leading to joint weakening and eventual failure. A durable, water-resistant finish minimizes these effects, stabilizing the wood and preserving the integrity of the joinery. For example, a catalyzed lacquer finish provides a robust barrier against moisture and chemicals, extending the lifespan of the furniture.

These facets underscore the critical role of structural integrity in guaranteeing the long-term functionality and stability. Careful consideration of wood selection, joinery techniques, leg geometry, and finish application is crucial in the design and construction. Failure to address these elements can result in a furniture piece that is aesthetically pleasing but structurally unsound, ultimately compromising its value and utility.

Frequently Asked Questions

The following section addresses common inquiries regarding the selection, care, and characteristics of tables featuring lathe-shaped supports.

Question 1: What distinguishes a lathe-shaped support from a standard table leg?

Lathe-shaped supports are formed through a subtractive manufacturing process on a lathe, imparting decorative contours and symmetrical profiles that are typically absent in standard, non-turned table legs. This process allows for intricate designs and consistent shapes that are difficult to achieve through other woodworking methods.

Question 2: Which wood types are best suited for constructing tables with lathe-shaped supports?

Hardwoods such as maple, oak, walnut, and cherry are generally preferred due to their strength, stability, and ability to hold intricate details during the turning process. Softwoods, while less expensive, are more prone to damage and may not support complex designs as effectively.

Question 3: How should a table with lathe-shaped supports be cleaned and maintained?

Regular dusting with a soft cloth is recommended to remove surface debris. For deeper cleaning, a mild soap solution can be used, followed by thorough drying. Avoid using harsh chemicals or abrasive cleaners, as these can damage the finish. Periodic application of a furniture polish or wax can help protect and enhance the wood’s luster.

Question 4: What are the common causes of damage to tables with lathe-shaped supports?

Common causes of damage include exposure to excessive moisture, direct sunlight, and physical impacts. Moisture can lead to warping and cracking, while sunlight can cause fading and discoloration. Impacts can result in dents, scratches, or even structural failure of the supports.

Question 5: Can lathe-shaped supports be repaired if they are damaged?

Minor scratches and dents can often be repaired with touch-up finishes or wood fillers. More significant damage, such as cracks or breaks, may require professional repair or replacement of the entire support. The feasibility and cost of repair depend on the extent of the damage and the complexity of the design.

Question 6: How does the style of the lathe-shaped supports influence the overall aesthetic of the table?

The style of the supports plays a crucial role in determining the table’s aesthetic character. Simple, minimalist turnings lend a contemporary feel, while ornate, decorative turnings evoke a more traditional or elaborate style. The design of the supports should complement the tabletop shape and the surrounding decor to create a cohesive and harmonious look.

These responses provide valuable insights into the essential aspects. Considering these elements contributes to well-informed decisions and ensures the continued enjoyment of this furniture.

The next section will delve into specific design considerations for integrating this type of table into various interior styles, providing practical guidance for creating cohesive and aesthetically pleasing spaces.

Conclusion

This exploration has illuminated the multifaceted nature of the turned leg coffee table. From the selection of durable hardwoods and the intricacies of turning styles to the functional considerations of tabletop shape and the safeguarding role of a robust finish, each element contributes to the piece’s lasting value and aesthetic contribution. The understanding of structural integrity ensures its stability and longevity, while proactive care preserves its beauty for years to come.

Selecting a turned leg coffee table represents more than a mere purchase. It embodies a commitment to craftsmanship, an appreciation for design, and an investment in a piece of furniture destined to become a focal point of the living space. Further exploration of individual styles and construction techniques will yield a more personalized and informed choice.