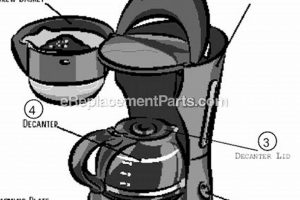

Components vital to the function of a popular home brewing appliance are the focus. These items range from the carafe and filter basket to heating elements and water reservoirs. For example, a replacement carafe might be necessary if the original is broken, rendering the entire unit unusable.

The availability of these individual pieces extends the lifespan of the coffee maker, offering a cost-effective alternative to complete replacement. This also reduces waste, aligning with environmentally conscious practices. Historically, the ability to obtain separate components has been a key factor in the brand’s widespread appeal and user loyalty.

The subsequent sections will delve into specific categories of these essential items, examining their function, common issues, and where they can be sourced. This will equip the reader with a comprehensive understanding of maintaining and repairing their coffee brewing device.

Essential Guidance for Maintaining Coffee Brewing Appliance Components

Maintaining these specific components ensures the longevity and optimal performance of the appliance. Adhering to the following guidelines can significantly extend the usability and reliability of the machine.

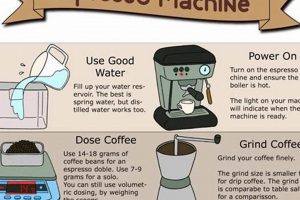

Tip 1: Regular Cleaning of the Filter Basket: Mineral deposits and coffee residue accumulate within the filter basket, affecting the taste of the brewed coffee and potentially clogging the unit. Clean the basket after each use with warm, soapy water.

Tip 2: Descaling the Water Reservoir: Mineral buildup within the water reservoir reduces heating efficiency and alters the flavor profile. Descale the reservoir monthly using a commercial descaling solution or a mixture of water and white vinegar.

Tip 3: Inspecting the Carafe for Cracks: A cracked carafe poses a safety risk and impairs the unit’s functionality. Routinely inspect the carafe for any signs of damage and replace it immediately if cracks are detected.

Tip 4: Checking the Heating Element: The heating element is crucial for water heating. If the coffee maker fails to heat the water, the heating element may be faulty and require professional inspection or replacement.

Tip 5: Replacing the Filter: Using correct filter can affect the taste of the coffee. Replace the filter after each use.

Tip 6: Inspecting power cord and replace it If the power cord damage it need to replace or it will cause short circuit

Implementing these straightforward maintenance practices helps to prevent malfunctions, ensures consistent brewing quality, and extends the overall life of the coffee maker.

The concluding section will summarize the importance of regular maintenance and offer guidance on identifying and sourcing suitable replacement components.

1. Carafe Availability

The ready availability of a replacement carafe is intrinsically linked to the overall viability and lifespan of a particular coffee maker. The carafe, a fundamental component for collecting brewed coffee, is susceptible to breakage through accidental impact or thermal shock. Consequently, if a replacement is unobtainable, the entire coffee maker unit effectively becomes non-functional, rendering the remaining components unusable. The accessibility of carafes is therefore a crucial factor in the practical utility of the appliance.

Manufacturers that prioritize the sustained availability of replacement carafes enhance consumer satisfaction and foster brand loyalty. For example, a customer whose carafe breaks is more likely to purchase a replacement carafe, rather than a complete new unit, if the replacement is readily available at a reasonable cost. This reduces electronic waste and provides a more economical solution for the consumer. Conversely, a lack of replacement carafes can lead to product obsolescence and consumer frustration, potentially damaging the brand’s reputation.

In summary, the strategic management of carafe availability is not merely a logistical concern but a critical aspect of product lifecycle management. A proactive approach to providing replacement carafes contributes to consumer satisfaction, minimizes waste, and reinforces the perceived value and durability of the coffee maker itself. The absence of such a strategy negates the utility of the other components, essentially compromising the functionality of the entire appliance.

2. Filter basket types

The filter basket constitutes a fundamental element within the architecture of a coffee maker. Its design and material composition directly influence the quality of the brewed coffee and the ease of operation. Varied filter basket types exist as distinct components, each interacting uniquely within the broader assembly of a coffee maker. For instance, a mesh filter basket eliminates the need for disposable paper filters, offering an economic and environmentally conscious alternative, while a plastic basket necessitates the consistent use of paper filters, impacting recurring costs and waste generation. The choice and condition of the filter basket inextricably determine the brewing outcome and user experience.

Consider the scenario of a coffee maker originally equipped with a gold-tone filter basket. Over time, this basket might become clogged with mineral deposits or damaged, necessitating replacement. Sourcing a compatible, if not identical, replacement becomes critical to maintaining the original brewing parameters. Substituting a different filter basket type for example, switching from a mesh to a plastic basket alters the flow rate, sediment control, and ultimately, the taste profile of the brewed coffee. This highlights the crucial role of selecting the appropriate filter basket as a component.

In summary, filter basket types form an indispensable aspect of coffee maker parts. Recognizing the interplay between the filter baskets characteristics and the resultant brew allows users to optimize their coffee-making process. Challenges arise in ensuring compatibility and sourcing exact replacements for older models. However, a clear understanding of filter basket functions, coupled with mindful selection, guarantees consistent brewing performance and extends the functional lifespan of the appliance.

3. Heating element function

The operational integrity of a coffee maker is fundamentally dependent on the heating element’s functionality. As a core component, its purpose is to elevate the water temperature to the optimal brewing range. Its failure precipitates a complete cessation of the brewing process, thus rendering the coffee maker unusable.

- Resistance Heating Principles

The heating element typically employs resistance heating, converting electrical energy into thermal energy. A resistive coil, constructed from a material such as nichrome, impedes the flow of electricity, resulting in heat generation. The efficiency of this conversion, and the evenness of heat distribution, directly impacts the final water temperature and brewing consistency. Deviations from the designed resistance values can lead to under-heating, over-heating, or complete failure.

- Thermostat Regulation

A thermostat, intrinsically linked to the heating element, regulates its operation by monitoring water temperature. The thermostat functions as a switch, interrupting the electrical circuit once the desired temperature threshold is reached. Malfunctioning thermostats may cause the heating element to continuously heat, posing a safety hazard, or fail to activate altogether, preventing the brewing cycle from commencing.

- Material Degradation and Scale Buildup

Prolonged exposure to water and high temperatures inevitably leads to material degradation within the heating element. Mineral scale deposits, accumulated from hard water sources, further impede heat transfer and accelerate component failure. Periodic descaling, using appropriate cleaning agents, mitigates scale buildup and extends the heating element’s functional lifespan.

- Safety Mechanisms and Overload Protection

Integrated safety mechanisms are essential to prevent overheating and potential fire hazards. Thermal fuses, designed to permanently interrupt the circuit in the event of excessive temperature, serve as a critical fail-safe measure. Similarly, overload protection circuits safeguard the heating element from voltage spikes and current surges, minimizing the risk of premature component failure.

Understanding the heating element’s multifaceted function is crucial for diagnosing coffee maker malfunctions. Identifying deviations from normal operating parameters, such as insufficient heating or erratic temperature regulation, allows for targeted troubleshooting and component replacement. The interplay between heating element design, thermostat control, and preventive maintenance ultimately determines the appliance’s reliability and longevity.

4. Water reservoir capacity

The water reservoir’s capacity, a critical specification of coffee maker components, directly influences the unit’s brewing capabilities. The stated volume dictates the maximum amount of coffee that can be brewed in a single cycle, representing a fundamental constraint on operational parameters. A smaller reservoir necessitates more frequent refills, while a larger one offers greater convenience for brewing multiple cups or serving a group. This element, therefore, impacts user experience and operational efficiency.

The size of the reservoir affects the design and selection of other components, such as the heating element and pump. A larger capacity requires a more powerful heating element to ensure consistent water temperature throughout the brewing cycle. The pump must also be capable of delivering sufficient water pressure to saturate the coffee grounds effectively. For example, a home coffee maker with a 12-cup reservoir requires a correspondingly robust heating element and pump compared to a smaller 4-cup model. Furthermore, the materials used in the reservoir’s construction must be food-safe and able to withstand repeated exposure to hot water.

Understanding water reservoir capacity, therefore, has practical significance in several areas. For manufacturers, it is a key design consideration, influencing component selection and overall product performance. For consumers, it informs purchasing decisions based on individual brewing needs and preferences. This capacity dictates the unit’s brewing capabilities, design constraints, and material selection. Maintaining the reservoir in good condition, free from cracks or leaks, is essential for the coffee maker’s continued functionality.

5. Control panel components

Control panel components are integral to the operation of coffee brewing appliances. These elements constitute the user interface, enabling control over various brewing parameters. Their functionality directly impacts the usability and features of the coffee maker.

The control panel comprises switches, buttons, displays, and internal circuitry. These components relay user commands to the internal mechanisms, governing brewing time, strength settings, and automated functions like pre-programmed start times. For instance, a malfunctioning power switch renders the entire appliance inoperable, irrespective of the functionality of other components. Similarly, a defective display screen hinders user feedback, making it difficult to monitor the brewing process or program settings. The reliability and responsiveness of these components are crucial for a satisfactory user experience. Modern appliances often incorporate sophisticated digital displays and touch-sensitive controls, adding complexity but also expanding functionality. A broken button affects the functionality of control panel components of coffee maker.

Effective control panel functionality requires careful design and robust construction. The components must withstand repeated use and environmental factors, such as humidity and heat. Understanding the interdependence of these elements and their impact on the overall operation of the coffee maker facilitates troubleshooting and repair efforts. This detailed knowledge is essential for both service technicians and informed users aiming to maintain their appliances.

6. Power Cord Safety

Power cord safety is a crucial, yet often overlooked, aspect of maintaining a functional coffee brewing appliance. The power cord serves as the essential conduit for electrical energy, supplying the necessary power to all internal components, including the heating element, pump, and control panel. Damage to the power cord, such as fraying, cuts, or exposed wires, presents a significant electrical hazard, posing risks of shock, fire, and potential equipment failure. Given the high-wattage nature of coffee makers, the power cord must be in proper condition and adequately rated to handle the electrical load. The power cord is an essential part of the coffee maker to make it function.

A compromised power cord not only poses a safety risk but also directly impacts the functionality of the coffee maker. Intermittent power supply due to a damaged cord can lead to inconsistent brewing cycles, temperature fluctuations, and ultimately, complete failure of the appliance. Regularly inspecting the power cord for any signs of wear or damage is a critical preventative measure. If damage is detected, the cord should be immediately replaced with a properly rated replacement. Ignoring power cord safety can lead to dangerous and costly consequences. For example, if the cord is not functioning properly it will cause a short circuit to the coffee maker.

In summary, prioritizing power cord safety is integral to ensuring the safe and reliable operation of coffee brewing appliances. Regular inspections, prompt replacement of damaged cords, and adherence to manufacturer guidelines regarding cord usage are essential. Addressing potential hazards proactively minimizes the risk of electrical incidents and prolongs the lifespan of the appliance. The integrity of the power cord forms a non-negotiable prerequisite for the safe and effective functioning of any coffee maker.

7. Replacement part sourcing

The availability of replacement components directly determines the lifespan and usability of “mr coffee maker parts.” Component sourcing, therefore, is not merely a logistical concern, but a core factor in the economic and environmental viability of these appliances. A broken carafe or a malfunctioning heating element does not necessitate the disposal of the entire unit if compatible replacement parts are accessible. This accessibility reduces waste and lowers the overall cost of appliance ownership.

Effective replacement part sourcing requires manufacturers to prioritize the continued production and distribution of individual components, beyond the initial sale of the complete coffee maker. Third-party suppliers also play a crucial role in providing aftermarket components, catering to older models or offering alternative options. However, consumers face the challenge of verifying the compatibility and quality of these replacement parts. Non-genuine components may compromise the appliance’s performance or even present safety risks. A malfunctioning heating element can cause a short circuit if it is not the right part.

In summary, efficient replacement part sourcing is essential for extending the lifespan and maximizing the value of “mr coffee maker parts.” While manufacturers and third-party suppliers contribute to the availability of these components, consumers must exercise caution and verify the compatibility and quality of any replacements. This ensures safe and effective appliance repair, reducing waste and promoting sustainable consumption practices.

Frequently Asked Questions

The following section addresses common inquiries regarding the components that comprise a standard coffee brewing appliance. Understanding these elements facilitates effective maintenance and troubleshooting.

Question 1: Where can one reliably source replacement carafes for discontinued coffee maker models?

Replacement carafes for discontinued models can often be found through online retailers specializing in appliance parts or from authorized service centers that maintain inventories of older components. Specifying the exact model number is crucial for ensuring compatibility.

Question 2: How does the type of filter basket affect the resulting coffee flavor?

Filter basket material, design, and mesh size influence the flow rate and sediment retention during brewing. Mesh filters tend to produce a bolder flavor due to increased sediment, while paper filters yield a cleaner, less sediment-laden brew.

Question 3: What are the primary causes of heating element failure in coffee makers?

Heating element failure typically results from mineral scale buildup, corrosion, or electrical overload. Regular descaling and adherence to recommended voltage specifications can mitigate these issues.

Question 4: What are the consequences of overfilling the water reservoir?

Overfilling the water reservoir can lead to water spillage, potentially damaging internal electrical components and creating a safety hazard. Adhering to the maximum fill line is essential.

Question 5: How does one troubleshoot a non-responsive control panel on a coffee maker?

Troubleshooting a non-responsive control panel involves checking the power supply, verifying the integrity of the wiring connections, and testing the individual buttons and switches. Component replacement may be necessary in cases of irreparable damage.

Question 6: What safety precautions should be observed when replacing a damaged power cord?

When replacing a damaged power cord, ensure that the replacement cord matches the original specifications in terms of gauge and voltage rating. Disconnect the appliance from the power source before commencing the repair and verify the secure connection of all wires.

Accurate understanding of these aspects can help prolong the life and performance of the coffee brewing appliance.

The subsequent section will address maintenance tips.

Conclusion

This exposition has detailed the critical facets of components related to a common coffee brewing appliance. The discussion encompassed component availability, functional necessity, and crucial maintenance. Understanding these diverse aspects enables informed decisions regarding repair, replacement, and preventative care. Prioritizing this knowledge directly impacts appliance longevity and user experience.

Effective utilization of this information promotes responsible consumption and minimizes unnecessary waste. Continued adherence to recommended maintenance protocols ensures consistent performance and reduces the likelihood of premature component failure. A proactive approach to appliance care provides both economic benefits and environmental advantages. It is incumbent upon users to apply this understanding to achieve optimal appliance performance and sustainable practices.

![Best Commercial Cold Press Coffee Maker [Guide & Reviews] The Ultimate Coffee Guide: Types, Brewing Methods & Best Beans Best Commercial Cold Press Coffee Maker [Guide & Reviews] | The Ultimate Coffee Guide: Types, Brewing Methods & Best Beans](https://deacoffee.com/wp-content/uploads/2026/02/th-87-300x200.jpg)