This component is a detachable cover, frequently circular, designed to fit securely on top of a drinking vessel, typically crafted from fired clay. Its purpose is to insulate the contained liquid, preserving its temperature for an extended period, and to prevent spills. An example includes a fitted top resting on a standard 12-ounce hot beverage container, effectively minimizing heat loss.

The implementation of this feature offers several advantages. It aids in maintaining beverage warmth, reducing the need for frequent reheating. Moreover, it provides a barrier against airborne contaminants, ensuring the liquid remains sanitary. Historically, similar covers have been employed to safeguard and insulate liquids in various vessels, evolving with advancements in materials and design.

The subsequent sections will delve into the diverse materials, manufacturing processes, and design considerations involved in creating these components. Furthermore, the discussion will extend to the aspects of maintenance, safety, and aesthetic appeal.

Tips for Optimal Use

The following are guidelines intended to maximize the functionality and longevity of this specialized component.

Tip 1: Proper Sealing: Ensure complete and secure contact between the cover’s rim and the container’s edge. This action minimizes heat escape and prevents spillage. For example, inspect the seal for any gaps before transporting the container.

Tip 2: Pre-Heating Considerations: Prior to filling, warming the cover with hot water can enhance thermal retention properties. This minimizes temperature shock and extends the duration the beverage remains warm.

Tip 3: Cleaning Procedures: After each use, thoroughly clean the cover with a non-abrasive cleaner and warm water. Residue build-up can compromise the seal and potentially harbor bacteria.

Tip 4: Careful Handling: Though durable, the cover is susceptible to damage from impact. Avoid dropping it onto hard surfaces, as this can lead to cracking or chipping, rendering it ineffective.

Tip 5: Storage Practices: Store the cover in a dry, safe location when not in use. This prevents damage and maintains its structural integrity.

Tip 6: Temperature Limitations: Exercise caution when using in microwave environments. Extreme temperatures could cause it to crack or become damaged. Refer to manufacturer’s instructions before microwaving.

Adhering to these guidelines can significantly extend the usability and effectiveness of the insulating cover, ensuring consistent performance.

The subsequent section will provide a concluding overview of the key aspects covered within this article.

1. Insulation

Insulation, in the context of a fired clay cover for a hot beverage container, is paramount to its functional performance. The ability of the cover to impede heat transfer directly impacts the temperature maintenance of the contained liquid, affecting the user’s experience.

- Material Properties

The inherent thermal conductivity of the material from which the cover is crafted is a primary determinant of its insulation effectiveness. Ceramic, while generally a poor conductor compared to metals, varies in density and composition, impacting its heat transfer rate. A denser ceramic may offer better structural integrity but could also be more conductive, requiring a balance in material selection.

- Air Gap Utilization

The design may incorporate an air gap between the cover and the container’s opening. Air is a poor conductor of heat; therefore, this gap can significantly reduce conductive heat loss. The effectiveness of this air gap depends on its width and the prevention of convection currents within the gap itself.

- Surface Finish and Color

The emissivity of the cover’s external surface influences radiative heat loss. A matte finish, compared to a glossy one, tends to increase emissivity, potentially leading to greater heat dissipation. Color also plays a role; darker colors generally absorb and emit more radiant heat than lighter colors.

- Cover Thickness and Design

A thicker cover provides a longer path for heat to travel, increasing resistance to heat transfer. Similarly, intricate designs that increase the surface area exposed to the air can enhance conductive and convective heat loss, necessitating a design approach that minimizes surface exposure while maximizing insulation.

Effective insulation for a fired clay cover involves careful consideration of material properties, design features, and surface characteristics. Optimization of these elements directly contributes to prolonged beverage temperature maintenance, enhancing user satisfaction and the overall utility of the hot beverage container.

2. Durability

Durability, in the context of a fired clay cover for beverage containers, refers to its ability to withstand wear, pressure, or damage. This characteristic is paramount to the longevity and reliability of the component, directly influencing its usability and perceived value.

- Material Composition and Firing Process

The inherent strength of a fired clay cover is heavily dependent on the specific ceramic composition and the firing process it undergoes. High-quality ceramic materials, when properly fired at appropriate temperatures, yield a dense, vitrified structure that is resistant to cracking and chipping. Conversely, poorly formulated ceramics or inadequate firing can result in a weaker, more brittle product prone to early failure. For example, a cover made from porcelain, known for its high strength and durability, will typically outperform one made from earthenware.

- Impact Resistance

A key measure of durability is the cover’s ability to withstand impact without fracturing. Accidental drops or collisions with other objects are common occurrences in daily use. A more robust cover will absorb impact energy more effectively, reducing the likelihood of damage. The design can also play a role, with rounded edges and thicker cross-sections providing greater resistance to impact forces. A cover with sharp edges, on the other hand, is more vulnerable to chipping.

- Thermal Shock Resistance

Sudden temperature changes can induce stress within the ceramic material, leading to cracking or shattering. Thermal shock resistance is therefore a critical aspect of durability. Covers designed to withstand rapid heating or cooling cycles, such as those experienced when pouring hot liquids or cleaning with cold water, will have a longer lifespan. This is often achieved through the use of specific ceramic formulations and controlled cooling processes after firing.

- Chemical Resistance

Exposure to various chemicals, such as detergents, acids, or bases, can gradually degrade the surface of a ceramic cover, affecting its structural integrity and appearance. High-quality, properly glazed covers are resistant to chemical attack, maintaining their strength and finish over time. A poorly glazed or unglazed cover, however, may be susceptible to staining, etching, or even structural weakening when exposed to aggressive chemicals.

The facets of material composition, impact resistance, thermal shock resistance, and chemical resistance are all intertwined in defining the durability of a fired clay cover. A cover exhibiting superior performance across these parameters ensures long-term usability and value, withstanding the rigors of daily use without succumbing to premature failure. Failure in any of these areas, however, will lead to a shortened lifespan and a diminished user experience.

3. Fit

The attribute of “Fit” is of paramount importance in the context of a fired clay cover for a hot beverage container. Precise and secure mating between the cover and the container’s rim is essential for optimal functionality, influencing both thermal performance and spill prevention.

- Dimensional Accuracy

Dimensional accuracy refers to the degree to which the cover’s inner diameter and the container’s outer diameter correspond. Inaccuracies, even minor ones, can compromise the seal, leading to heat loss and potential leakage. For instance, a cover with an inner diameter that is too large will not create a tight seal, allowing air to escape and potentially causing spills when the container is tilted. Conversely, a cover with an inner diameter that is too small may not fit onto the container at all, rendering it useless. Tolerances in manufacturing are critical; overly generous tolerances may lead to inconsistent “Fit” across different units of the same product line.

- Seal Integrity

Seal integrity refers to the effectiveness of the contact between the cover and the container in preventing the passage of liquids or gases. A well-designed cover will create a tight, impermeable seal that prevents spills and minimizes air exchange. The design of the sealing surface, whether it is a flat rim, a stepped rim, or a gasket, plays a crucial role in achieving this integrity. A cover with a damaged or poorly designed sealing surface will not create a secure seal, leading to leaks and a reduced ability to maintain beverage temperature. The presence of a gasket is useful, as the cover sits on the inside rim of the container preventing spills when tilted or inverted.

- Material Compatibility

Material compatibility influences the seal’s long-term performance. Differences in thermal expansion coefficients between the fired clay cover and the material of the beverage container can cause the “Fit” to change over time. If the cover and container expand or contract at different rates when exposed to temperature changes, the seal may loosen or tighten, potentially leading to leaks or cracking. Ideally, the materials should have similar thermal expansion properties to maintain a consistent “Fit” across a range of temperatures. In cases where the ceramic cover fits into the inside of the vessel, thermal expansion can impact the likelihood of cracking and shattering.

- Stability and Securement

A secure “Fit” ensures the cover remains firmly in place during normal use, preventing accidental dislodgement. The design may incorporate features such as friction ridges, locking mechanisms, or interference fits to enhance stability. A cover that is easily knocked off or that slides around on the container is not only inconvenient but also poses a safety hazard, particularly when containing hot liquids. The degree of force required to remove the cover should be balanced; it should be secure enough to prevent accidental removal but not so tight that it is difficult to remove intentionally.

These characteristics concerning “Fit” are interwoven in determining the overall functionality and safety of the fired clay cover. Suboptimal “Fit” in any of these aspects leads to compromise in its performance, ultimately diminishing the user experience and potentially posing risks. By optimizing dimensional accuracy, seal integrity, material compatibility, and securement, manufacturers can ensure that the fired clay cover provides reliable and safe performance throughout its intended lifespan.

4. Safety

The connection between safety and the fired clay cover for a hot beverage container is multifaceted, encompassing material composition, structural integrity, and user interaction. The potential for adverse effects, ranging from chemical leaching to physical injury, necessitates careful consideration of safety protocols throughout the design, manufacturing, and usage phases. Cause-and-effect relationships are prominent; for instance, the use of lead-based glazes can result in lead contamination of beverages, leading to serious health consequences. Structural weaknesses, such as hairline cracks, can cause sudden shattering when exposed to thermal stress, resulting in burns or cuts. The primary importance of safety as a component lies in preventing these adverse outcomes and ensuring user well-being.

Practical applications of this understanding are evident in the regulatory standards governing the production of ceramic food-contact articles. Agencies such as the Food and Drug Administration (FDA) in the United States set limits on the permissible levels of lead and cadmium that can leach from ceramicware. Manufacturers employ rigorous testing procedures to ensure compliance with these standards, safeguarding consumers from potential chemical hazards. Furthermore, design considerations play a crucial role. Smooth, rounded edges minimize the risk of cuts, while sturdy construction reduces the likelihood of breakage. The inclusion of steam vents can prevent pressure build-up within the container, mitigating the risk of explosive ejection of the cover. Proper labeling, including warnings about microwaving and temperature limitations, informs users about safe handling practices. The lid’s center of gravity must be directly over the mug, otherwise it becomes prone to tipping and spilling.

In summary, prioritizing safety in the design and manufacture of a fired clay cover for a hot beverage container involves a comprehensive approach that addresses material selection, structural integrity, and user awareness. While challenges remain, particularly in ensuring consistent adherence to safety standards across global supply chains, the integration of safety considerations into every stage of the product lifecycle is essential for protecting consumers and fostering trust. The broader theme of product safety underscores the responsibility of manufacturers to prioritize user well-being above all else.

5. Cleanliness

In the context of a fired clay cover for beverage containers, cleanliness assumes significant importance due to its direct impact on hygiene and potential influence on user health. The cover’s design and material properties must facilitate effective cleaning to prevent the accumulation of bacteria, mold, or beverage residue.

- Surface Porosity

The porosity of the ceramic material significantly affects its cleanability. Highly porous surfaces provide ample crevices for the entrapment of contaminants, making thorough cleaning challenging. Non-vitrified or improperly glazed ceramicware exhibits higher porosity, necessitating more rigorous cleaning methods to ensure sanitation. For instance, a porous cover may retain coffee oils even after washing, leading to bacterial growth and off-flavors. In contrast, a properly vitrified ceramic with a smooth, non-porous surface minimizes contaminant adhesion and simplifies cleaning procedures.

- Design Features

The cover’s design can either facilitate or hinder effective cleaning. Complex geometries, such as intricate patterns or deep grooves, create areas that are difficult to access and clean adequately. Simple, smooth designs with rounded edges are preferable, as they allow for easier cleaning and reduce the risk of residue accumulation. A cover with a deep, narrow groove along its rim, for example, may trap beverage residue that is difficult to remove with a standard sponge or brush.

- Glaze Composition and Durability

The type and quality of glaze applied to the ceramic cover influence its resistance to staining and scratching, both of which can impact its perceived cleanliness. Durable, stain-resistant glazes maintain their appearance and are easier to clean than softer, more porous glazes. A cover with a scratched or stained surface may appear unclean even after washing, creating a negative perception of hygiene. High-quality glazes also resist degradation from repeated cleaning cycles, ensuring long-term cleanability.

- Dishwasher Compatibility

The ability to withstand the high temperatures and harsh detergents used in dishwashers is an important aspect of cleanability. Covers that are not dishwasher-safe may degrade over time, losing their glaze or developing cracks that harbor bacteria. Dishwasher-safe covers should be made from durable materials that can withstand these conditions without compromising their structural integrity or surface finish.

The various facets of surface porosity, design features, glaze composition and durability, and dishwasher compatibility all interact to determine the cleanliness of a fired clay cover. Prioritizing these considerations in the design and manufacturing processes is critical for producing covers that are both hygienic and user-friendly, minimizing the risk of contamination and promoting long-term user satisfaction.

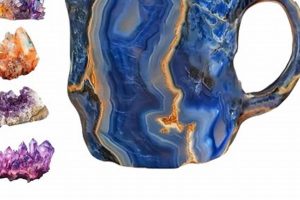

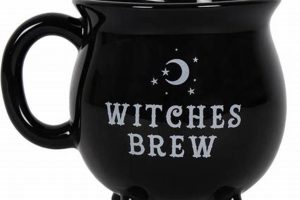

6. Aesthetics

Aesthetics, in the context of a fired clay cover for a hot beverage container, pertains to the visual appeal and perceived beauty of the object. It extends beyond mere functionality, encompassing design elements that contribute to the user’s sensory experience and overall satisfaction. The aesthetic design significantly impacts the perceived value and desirability of the product, influencing consumer choice and brand perception. A visually appealing cover can enhance the enjoyment of the beverage-drinking experience, transforming a routine act into a more pleasurable ritual. For example, a cover adorned with intricate patterns or a vibrant color can elevate the perceived quality of the beverage itself. Conversely, a poorly designed or aesthetically unappealing cover can detract from the overall experience, even if the cover functions perfectly in terms of insulation and spill prevention. The interplay between form and function is central to the aesthetic design of a fired clay cover; the design must not only be visually pleasing but also compatible with the intended use and manufacturing constraints. This creates a balancing act between aesthetic appeal and operational requirements.

Real-life examples of aesthetically driven fired clay covers abound in the marketplace. High-end coffee brands often invest heavily in the design of their lids, employing skilled artisans to create unique shapes, textures, and color palettes. These covers often feature embossed logos, intricate patterns, or hand-painted details, transforming them into miniature works of art. Other manufacturers prioritize minimalist designs, opting for sleek, unadorned covers that complement the clean lines of modern beverage containers. The choice of aesthetic style is often driven by brand identity and target market; a brand targeting younger consumers may opt for bold, vibrant colors and playful designs, while a brand catering to a more mature audience may favor more subdued, elegant aesthetics. There are many styles, such as rustic, contemporary, classic, or whimsical, with each style evoking a different mood and appealing to different sensibilities. The design needs to be carefully considered to align with the manufacturers objectives.

In summary, aesthetics plays a crucial role in the overall appeal and perceived value of a fired clay cover. While challenges may exist in balancing aesthetic considerations with functional requirements and manufacturing constraints, the investment in thoughtful design can yield significant returns in terms of consumer satisfaction and brand recognition. Ultimately, the aesthetic design of a fired clay cover contributes to the broader theme of creating products that are not only functional but also visually pleasing and emotionally engaging, enhancing the user’s overall experience and fostering a deeper connection with the product and brand.

Frequently Asked Questions

The subsequent section addresses common inquiries regarding the function, maintenance, and safety of this specific component.

Question 1: What is the optimal method for cleaning a ceramic cover?

Abrasive cleaners should be avoided. Warm water and a mild dish soap are generally sufficient. For stubborn stains, a paste of baking soda and water can be applied gently.

Question 2: Is it safe to microwave a ceramic cover?

Some ceramic covers are microwave-safe, but it is crucial to verify this information with the manufacturer’s instructions. Metallic accents or certain glazes may render a cover unsuitable for microwave use.

Question 3: How does the material of the cover affect heat retention?

Density and composition of the ceramic influence thermal conductivity. A denser ceramic typically retains heat more effectively, but material blends impact this characteristic.

Question 4: What is the best way to prevent a ceramic cover from cracking?

Avoid rapid temperature changes and impacts. Gradual heating and cooling, along with careful handling, are critical for preventing thermal shock and physical damage.

Question 5: How can one ensure a proper seal between the cover and the mug?

The cover and mug must be designed with precise dimensional tolerances. Inspection for chips or irregularities on the rim of both components is recommended.

Question 6: Can a ceramic cover leach harmful substances into the beverage?

If the cover is manufactured using lead-free glazes and adheres to relevant safety standards, the risk of leaching is minimal. Verification of compliance with regulations is essential.

This FAQ section provides a concise overview of essential considerations regarding this type of component.

The subsequent section offers a conclusion of the topics discussed within this article.

Conclusion

This exploration has illuminated the multifaceted nature of the coffee mug ceramic lid, encompassing its design, functionality, safety, and aesthetic dimensions. Key points addressed include the significance of material composition, thermal properties, structural integrity, cleanability, and adherence to regulatory standards. The importance of a precise fit between the cover and the mug, alongside user safety, has been underlined.

Continued advancements in materials science and manufacturing techniques hold the potential to further enhance the performance and safety of this ubiquitous component. Emphasis on sustainable manufacturing practices and consumer awareness of proper usage and care will contribute to the longevity and utility of the coffee mug ceramic lid, ensuring its continued role in the enjoyment of hot beverages.

![Best 8 Ounce Travel Coffee Mug [Portable Size!] Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Best 8 Ounce Travel Coffee Mug [Portable Size!] | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://deacoffee.com/wp-content/uploads/2025/06/th-2621-300x200.jpg)

![Best Campfire Coffee Mugs [Outdoor Gear] Reviews Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Best Campfire Coffee Mugs [Outdoor Gear] Reviews | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://deacoffee.com/wp-content/uploads/2025/06/th-2033-300x200.jpg)