Acquiring substantial quantities of raw coffee material represents a procurement strategy focused on volume. This approach contrasts with purchasing smaller, retail-packaged amounts. For instance, a caf anticipating high demand might opt to secure a large shipment from a distributor rather than repeatedly purchasing individual bags from a local supplier.

The practice offers potential advantages in cost savings, supply chain simplification, and inventory management. Historically, this method has been employed by large-scale roasters and distributors to ensure a consistent supply and mitigate price fluctuations. It allows businesses to negotiate favorable pricing and build long-term relationships with producers or wholesalers.

The following sections will detail various aspects of sourcing large quantities of raw coffee, including considerations for selection, storage, roasting, and potential applications across different business models.

Considerations for Purchasing Substantial Quantities of Coffee Beans

The acquisition of significant amounts of raw coffee requires careful planning and execution to maximize benefits and minimize potential risks. The following points outline critical considerations for businesses engaging in such purchases.

Tip 1: Source Verification. Prioritize traceability and verification of origin. Independent certifications or direct relationships with farmers provide assurance of quality and ethical sourcing practices.

Tip 2: Quality Assessment. Conduct thorough quality evaluations, including cupping and visual inspection, before committing to a large order. Sample roasts are essential to assessing flavor profiles and potential defects.

Tip 3: Storage Capacity. Ensure adequate storage facilities are available to maintain bean quality. Ideal conditions involve climate control, low humidity, and protection from direct sunlight. Improper storage leads to degradation and loss of flavor.

Tip 4: Contract Negotiation. Secure favorable contract terms that address price fluctuations, quality guarantees, and delivery schedules. Consider options for hedging or price locking to mitigate market volatility.

Tip 5: Roasting Capabilities. Evaluate roasting capacity and efficiency. Large-scale purchases necessitate optimized roasting schedules and consistent quality control measures.

Tip 6: Inventory Management. Implement robust inventory management systems to track bean age, roast dates, and usage rates. First-in, first-out (FIFO) inventory management minimizes waste and ensures optimal freshness.

Tip 7: Supplier Relationships. Cultivate strong relationships with suppliers. Consistent communication and collaboration can lead to preferential pricing, access to exclusive lots, and early notification of market trends.

Strategic planning across sourcing, storage, roasting, and distribution is vital for successfully leveraging the advantages of bulk coffee acquisition. Effective implementation translates to cost savings, enhanced quality control, and a stable supply chain.

The subsequent section will explore the roasting process.

1. Economies of Scale

Economies of scale, in the context of acquiring coffee beans in large quantities, represent a significant driver of cost reduction and operational efficiency for businesses. By leveraging increased purchasing power, companies can secure more favorable pricing and optimize various aspects of their supply chain.

- Reduced Unit Cost

Purchasing substantial quantities of coffee beans often results in a lower per-unit cost compared to smaller, more frequent acquisitions. Suppliers typically offer volume discounts, reflecting savings in packaging, handling, and administrative overhead. This direct cost reduction enhances profitability for roasters and retailers.

- Negotiating Power

Large-volume purchasers possess greater negotiating leverage with suppliers. This allows for the establishment of more favorable contract terms, including payment schedules, quality guarantees, and preferential access to specific bean varieties or harvest seasons. Enhanced negotiating power translates to improved financial and operational stability.

- Streamlined Logistics

Consolidated shipments reduce transportation costs and simplify logistical operations. Instead of managing multiple smaller deliveries, businesses can coordinate fewer, larger shipments, minimizing handling fees and transportation delays. This optimization contributes to supply chain efficiency and reduced inventory holding costs.

- Optimized Production Planning

Predictable bean availability, facilitated by large orders, enables businesses to streamline production schedules and minimize downtime. This predictability is critical for maintaining consistent product quality and meeting customer demand without disruptions. Effective production planning ensures optimal resource utilization and minimizes waste.

The benefits derived from economies of scale directly impact a business’s bottom line. Strategic implementation of large-volume purchasing strategies, coupled with efficient operational practices, contributes to a sustainable competitive advantage within the coffee industry.

2. Consistent Supply

Maintaining a reliable and predictable inflow of coffee beans is critical for businesses that rely on this commodity as a core component of their operations. Securing raw materials in substantial quantities directly influences the stability and efficiency of their supply chain.

- Operational Stability

A guaranteed source of coffee beans minimizes disruptions to production schedules. Predictable availability allows roasters and retailers to fulfill customer orders without delays. A stable supply chain is a prerequisite for consistent product offerings and brand reputation.

- Price Volatility Mitigation

Long-term contracts for significant volumes can buffer against price fluctuations in the coffee market. Locking in pricing at predetermined levels provides financial predictability, protecting businesses from unforeseen cost increases caused by weather events, political instability, or shifts in global demand.

- Inventory Management Efficiency

Predictable delivery schedules simplify inventory management, reducing the risk of stockouts and minimizing excess inventory holding costs. Efficient inventory practices optimize cash flow and reduce storage-related expenses. Forecasting demand and aligning procurement strategies are essential for inventory optimization.

- Strategic Growth Enablement

A secure supply of coffee beans supports expansion plans and new product development. Businesses confident in their access to raw materials can invest in growth initiatives without concern for supply chain limitations. Reliable access to resources fuels innovation and market expansion.

A strategy focused on acquiring large quantities of coffee beans offers a pathway to achieve consistent supply. The establishment of robust supplier relationships, coupled with proactive planning and efficient inventory management, contributes significantly to the stability and resilience of a coffee-dependent business.

3. Storage Requirements

Proper storage is paramount when dealing with substantial quantities of coffee beans. Neglecting optimal storage conditions can negate the cost benefits achieved through bulk purchasing and compromise the quality of the final product.

- Environmental Control

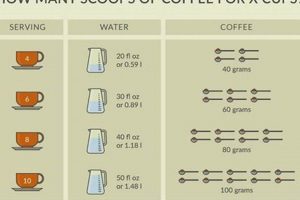

Coffee beans are highly susceptible to degradation from exposure to moisture, heat, and light. Storage facilities must maintain a stable environment, ideally with controlled temperature (between 60-70F) and humidity (around 50-60%). For example, a poorly ventilated warehouse in a humid climate can lead to mold growth and significant flavor loss. Proper environmental control preserves bean integrity and extends shelf life.

- Packaging Integrity

The packaging used for bulk storage should provide an effective barrier against external elements. Options include airtight bags or containers made of materials that prevent oxygen transmission. Improper packaging can lead to oxidation, staling, and the absorption of unwanted odors. Maintaining packaging integrity is essential for preventing flavor deterioration.

- Pest Management

Bulk storage creates an environment conducive to pest infestation. Regular inspections and preventative measures, such as pest control treatments, are necessary to protect against insects and rodents. Infestation can lead to significant product loss and contamination. Implementing a robust pest management program is crucial for maintaining product safety and preventing financial losses.

- Stacking and Handling Procedures

Improper stacking and handling can damage coffee bean packaging, leading to spills and exposure to the environment. Palletization and proper lifting equipment are essential for safely moving and storing large quantities of beans. Careless handling can compromise packaging integrity and increase the risk of product spoilage or damage.

Effective management of storage requirements is an integral component of a successful bulk coffee bean procurement strategy. Investing in appropriate storage facilities, packaging, and handling procedures ensures that the cost advantages gained through bulk purchasing are not offset by product spoilage or quality degradation.

4. Roasting Capacity

Roasting capacity is a critical factor for businesses engaging in the procurement of substantial quantities of coffee beans. The ability to process raw beans efficiently and effectively dictates the extent to which the cost and logistical advantages of bulk purchasing can be realized.

- Matching Capacity to Volume

The roasting infrastructure must be appropriately sized to handle the volume of green coffee acquired. Under-capacity leads to bottlenecks, delays, and potential spoilage of unroasted beans. For example, a roastery purchasing a container of green beans (approximately 40,000 lbs) needs the equipment to process that volume within a reasonable timeframe to maintain freshness. Mismatched capacity negates the economic benefits of bulk acquisition.

- Roasting Schedule Optimization

Large-scale green coffee inventory necessitates a well-defined roasting schedule. Efficient scheduling maximizes roaster utilization, minimizes energy consumption, and ensures timely fulfillment of orders. A poorly planned schedule can result in inconsistent roast profiles, increased labor costs, and delays in product delivery. Optimized scheduling is essential for efficient processing of bulk bean purchases.

- Equipment Maintenance and Reliability

Consistent operation of roasting equipment is crucial for maintaining throughput and minimizing downtime. Regular maintenance and preventative repairs are essential for ensuring the reliable operation of roasters and related equipment. A breakdown can lead to significant disruptions in the production schedule and potential spoilage of green coffee. Reliability is a key consideration when managing bulk inventories.

- Quality Control Implications

Increased roasting volume necessitates stringent quality control measures. Consistent monitoring of roast profiles, bean temperature, and color development is essential for maintaining product uniformity. Insufficient quality control can lead to inconsistencies in flavor and aroma, impacting customer satisfaction. Robust quality control procedures are indispensable for processing large quantities of coffee beans while upholding product standards.

The interplay between roasting capacity and bulk coffee bean purchases determines the overall efficiency and profitability of the operation. Effective management of roasting infrastructure, scheduling, maintenance, and quality control are critical for maximizing the benefits of large-volume procurement strategies. Failure to adequately address these factors can diminish the economic advantages associated with bulk purchasing.

5. Quality Control and Large-Volume Coffee Bean Acquisition

Acquiring substantial quantities of coffee beans necessitates a stringent quality control program to mitigate risks associated with variability inherent in agricultural commodities. Failure to implement rigorous assessment procedures can result in significant economic losses and damage to brand reputation. As an example, a roaster purchasing a large lot of beans without adequate pre-shipment samples may discover a high percentage of defective beans upon arrival, rendering a portion of the inventory unusable and impacting profitability. The potential for compounded losses underscores the importance of robust quality control as an indispensable component of bulk purchasing strategies.

Effective quality control extends throughout the entire procurement process, from initial supplier evaluation to final product packaging. Activities encompass cupping samples to assess flavor profiles, visual inspection for defects (e.g., broken beans, insect damage), and moisture content analysis to ensure proper storage conditions. Consider the case of a specialty coffee company committed to sourcing only beans with a specific flavor profile. Rigorous cupping protocols, including multiple blind tastings conducted by trained professionals, are essential for identifying lots that meet the company’s exacting standards. This proactive approach prevents the incorporation of substandard beans into the production process, safeguarding product consistency and customer satisfaction.

In summary, the relationship between quality control and large-volume coffee bean purchases is direct and consequential. Investment in robust quality assurance mechanisms is not merely an operational expense but a strategic imperative for mitigating risk, protecting brand value, and maximizing the economic benefits of bulk procurement. Challenges such as evolving coffee bean grading standards and increasingly complex supply chains necessitate continuous refinement of quality control protocols. Ultimately, effective management of quality is integral to success in the competitive coffee market.

6. Supplier Relations

The procurement of coffee beans in bulk necessitates cultivating robust and mutually beneficial relationships with suppliers. The volume inherent in such purchases creates a dependency that elevates the supplier relationship from a transactional arrangement to a strategic partnership. Positive interactions foster trust, transparency, and information sharing, which are critical for mitigating risks associated with supply chain disruptions, quality inconsistencies, and price volatility. For instance, a roaster establishing a direct trade relationship with a coffee cooperative can gain access to higher-quality beans at stable prices, while simultaneously supporting sustainable farming practices and community development. The establishment of such partnerships requires significant upfront investment of time and resources, but offers long-term benefits in terms of supply chain security and enhanced product differentiation.

Effective supplier relations involve open communication channels, regular performance evaluations, and collaborative problem-solving. Consider a scenario where a weather event impacts a key coffee-producing region. A roaster with strong supplier ties is more likely to receive early notification of potential supply shortages, allowing them to adjust their procurement strategy and minimize disruptions to their operations. Conversely, a roaster relying solely on spot market purchases may face sudden price spikes or inability to secure adequate supply. Supplier relations facilitate the exchange of valuable information regarding market trends, crop forecasts, and quality issues. This information empowers buyers to make informed decisions, optimize inventory management, and proactively address potential challenges.

In conclusion, supplier relations are integral to successful bulk coffee bean procurement. By prioritizing relationship building, clear communication, and collaborative problem-solving, businesses can mitigate risks, enhance supply chain resilience, and gain a competitive advantage. Challenges such as geographic distance, cultural differences, and language barriers necessitate ongoing effort and investment in cultivating and maintaining strong supplier partnerships. Ultimately, the effectiveness of these relationships directly influences a company’s ability to secure a consistent supply of high-quality coffee beans at competitive prices, contributing to long-term sustainability and profitability.

Frequently Asked Questions

This section addresses common inquiries regarding the purchase and utilization of coffee beans in substantial quantities, providing insights for businesses and individuals considering this procurement strategy.

Question 1: What constitutes “coffee beans in bulk”?

The term generally refers to purchasing quantities exceeding typical retail sizes, often measured in kilograms or pounds. The specific threshold varies depending on the supplier and the intended application. For example, a small cafe may consider 50 lbs a bulk purchase, while a large roaster may only consider orders over 1000 lbs to qualify.

Question 2: What are the primary benefits of acquiring coffee beans in bulk?

The primary benefits include potential cost savings through volume discounts, reduced shipping frequency, and streamlined inventory management. Bulk purchases also offer greater control over sourcing and blending, enabling consistent product quality.

Question 3: What are the key considerations for storing large quantities of coffee beans?

Proper storage is crucial to maintain freshness and prevent degradation. Ideal conditions include a cool, dry, dark environment, away from strong odors. Airtight containers are recommended to minimize oxygen exposure. Maintaining consistent temperature and humidity levels is also essential.

Question 4: How does bulk purchasing impact roasting practices?

Bulk purchases require adequate roasting capacity and efficient scheduling to ensure timely processing and prevent bean spoilage. Consistent quality control measures are essential to maintain uniform roast profiles across large batches. Attention to detail is paramount.

Question 5: What are the potential drawbacks of acquiring coffee beans in bulk?

Drawbacks may include the need for significant upfront investment, the risk of bean spoilage due to improper storage, and potential losses if market prices decline after purchase. Accurate demand forecasting is essential to avoid overstocking.

Question 6: How does one ensure the quality and ethical sourcing of coffee beans purchased in bulk?

Traceability and certification are key. Direct trade relationships with farmers or cooperatives offer greater transparency and control over sourcing practices. Independent certifications, such as Fair Trade or Rainforest Alliance, provide assurance of ethical and sustainable production. Reputable suppliers should be able to provide detailed information about the origin and processing of their beans.

In conclusion, acquiring coffee beans in bulk presents both opportunities and challenges. Careful planning, informed decision-making, and adherence to best practices are essential for maximizing the benefits and mitigating the risks associated with this procurement strategy.

The subsequent sections will delve into specific case studies.

Conclusion

This exploration of coffee beans in bulk has underscored the critical aspects of this procurement strategy. From the economic advantages of scale to the logistical considerations of storage and roasting, the article has presented a detailed overview. Successful implementation requires careful planning, robust quality control, and the cultivation of strong supplier relationships to mitigate risks and optimize benefits.

As the coffee industry continues to evolve, a comprehensive understanding of the factors influencing bulk procurement becomes increasingly vital. Businesses should consider the presented insights to inform their sourcing decisions and ensure a sustainable, efficient, and profitable supply chain. Prudent evaluation and execution are essential for realizing the full potential of coffee beans in bulk.