Earthenware vessels, specifically designed for the consumption of hot beverages, are often crafted from various types of refined earth. These containers, typically featuring a handle for ease of use, are heated to high temperatures during manufacturing to achieve durability and impermeability. A common example includes a handcrafted item sourced from local potteries, used daily for morning coffee.

The significance of these vessels extends beyond mere functionality. They provide a tangible connection to artisanal traditions and offer an alternative to mass-produced items. Furthermore, the inherent thermal properties of the material can contribute to maintaining the beverage’s temperature for extended periods. Historically, similar receptacles have been used for centuries across diverse cultures for ritualistic and everyday purposes, highlighting their enduring importance.

The subsequent sections will delve into the specific types of earth employed in their creation, the various glazing techniques used to enhance their aesthetic appeal and protect the material, and the potential impacts of their production and disposal on the environment.

Clay Coffee Mugs

Proper handling and care will extend the lifespan and preserve the aesthetic qualities of earthenware beverage containers.

Tip 1: Preheat Before Use. Rapid temperature changes can induce stress fractures in the material. Introduce hot liquid gradually by first warming the interior with hot tap water.

Tip 2: Hand Washing Recommended. While some varieties may be dishwasher safe, hand washing with a non-abrasive sponge and mild detergent is a gentler approach that reduces the risk of chipping or glaze degradation.

Tip 3: Avoid Microwave Use Unless Specified. Metallic components in some glazes can cause arcing in microwave ovens. Verify microwave compatibility with the manufacturer before use.

Tip 4: Protect From Impact. The inherent fragility of the material renders it susceptible to breakage from impact. Store carefully to prevent accidental drops or collisions.

Tip 5: Manage Staining. Tannins in coffee and tea can cause staining. Regular cleaning with baking soda and water can help to remove these discolorations.

Tip 6: Ensure Complete Drying. After washing, ensure the item is thoroughly dried before storing to prevent moisture absorption, which can lead to mold growth or weakening of the clay structure.

Tip 7: Inspect for Cracks. Regularly examine the surface for any hairline cracks. These can expand with continued use, eventually leading to structural failure.

Adhering to these guidelines will help to preserve the integrity and prolong the usability of earthenware beverage containers, ensuring continued enjoyment.

The subsequent section will address the environmental considerations associated with the production and disposal of these items.

1. Material Composition

The primary determinant of a clay coffee mug’s functionality and longevity is its material composition. Various types of earth, including earthenware, stoneware, and porcelain, exhibit distinct characteristics that directly impact the finished product. Earthenware, typically fired at lower temperatures, results in a porous body requiring glazing for impermeability. Stoneware, fired at higher temperatures, achieves a vitrified state, offering increased durability and reduced porosity. Porcelain, characterized by its fine particle size and high firing temperature, yields a translucent and exceptionally strong vessel. The choice of material significantly influences the mug’s resistance to thermal shock, its ability to retain heat, and its susceptibility to chipping or cracking.

For instance, a mug crafted from low-fired earthenware might be prone to developing hairline cracks when subjected to rapid temperature changes, such as being transferred directly from a cold environment to a microwave. Conversely, a mug constructed from high-fired stoneware is less likely to exhibit this issue due to its increased density and reduced water absorption. Similarly, the presence of certain minerals within the earth can affect the final color and texture of the piece, influencing its aesthetic appeal. For example, the inclusion of iron oxide can impart a reddish hue, while the addition of feldspar can promote a smooth, glassy surface upon firing.

In summary, understanding the material composition of a clay coffee mug is essential for both manufacturers and consumers. It dictates the appropriate usage and care protocols, ensuring prolonged functionality and preventing premature degradation. Selecting the correct material, and understanding its properties, is crucial in determining the suitability of a mug for specific applications and temperature ranges.

2. Firing Temperature

Firing temperature is a critical determinant of the final properties and characteristics of earthenware beverage containers. This thermal process induces irreversible transformations in the raw earth, dictating its strength, porosity, and overall durability.

- Vitrification and Density

Elevated firing temperatures promote vitrification, a process where the earthen material partially melts and fuses together. This results in a denser structure with reduced porosity. Mugs fired at higher temperatures exhibit enhanced resistance to liquid absorption and are less susceptible to staining or cracking. For example, stoneware, fired at temperatures ranging from 2100F to 2300F, boasts superior density compared to earthenware fired at lower temperatures. The degree of vitrification directly correlates with the mug’s ability to withstand repeated use and dishwashing.

- Structural Strength and Durability

The crystalline structure of the earthen material is significantly altered during firing. Higher temperatures foster the development of stronger interatomic bonds, increasing the overall structural integrity of the mug. This enhanced strength translates to greater resistance to chipping, thermal shock, and mechanical stress. Earthenware mugs, due to their lower firing temperatures, are inherently more fragile and prone to damage compared to porcelain mugs fired at significantly higher temperatures.

- Glaze Integration and Bonding

Firing temperature plays a crucial role in the fusion of glaze with the earthen body. The glaze, a vitreous coating applied to the surface, provides impermeability and aesthetic appeal. The optimal firing temperature ensures proper melting and bonding of the glaze to the mug, creating a durable and seamless finish. Under-fired glazes may result in a rough, uneven surface, while over-fired glazes may run or blister. Proper glaze integration is essential for preventing the leaching of harmful substances and ensuring food safety.

In essence, the firing temperature represents a pivotal control variable in the manufacturing of earthenware beverage containers. Precisely calibrated temperatures are crucial for achieving the desired balance between strength, durability, and aesthetic appeal. The selection of an appropriate firing temperature is fundamental to producing a mug that meets both functional and aesthetic demands, ensuring its longevity and safe usage.

3. Glaze Type

The selection of glaze for earthenware beverage containers directly influences their functionality, safety, and aesthetic appeal. Glaze serves as a protective barrier, rendering the porous earth impermeable to liquids, while also providing a decorative finish. Diverse glaze formulations exist, each possessing unique properties and implications for the final product.

- Lead-Based Glazes

Historically, lead compounds were incorporated into glazes to achieve vibrant colors and a smooth, glossy surface at relatively low firing temperatures. However, lead is a neurotoxin, and its potential to leach into beverages poses a significant health risk. Consequently, lead-based glazes are now largely prohibited for use in food-contact applications. An example is antique earthenware, which may exhibit unusually bright colors but should not be used for consumption due to the risk of lead contamination.

- Lead-Free Glazes

Modern glazes are formulated without lead, utilizing alternative fluxes such as boron and alkaline oxides to achieve vitrification. These glazes prioritize consumer safety while still offering a wide range of colors and textures. The majority of commercially available coffee mugs are coated with lead-free glazes to comply with health regulations. It is critical that ceramic products intended for food use explicitly state that they are lead-free.

- Functional Glazes

Beyond aesthetics, glazes provide crucial functionality. They create a smooth, non-porous surface, preventing the absorption of liquids and facilitating cleaning. Glazes also enhance the durability of the earthenware, protecting it from scratches and chemical damage. For instance, a properly formulated glaze can prevent staining from coffee or tea, maintaining the mug’s appearance over time. The ability to withstand repeated dishwashing cycles is another important function conferred by glaze.

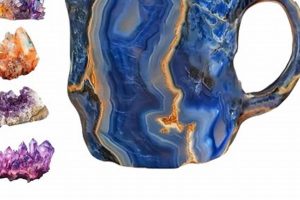

- Decorative Glazes

Glazes offer a vast palette for artistic expression. From matte to glossy finishes, transparent to opaque colors, and textured to smooth surfaces, glazes allow for endless design possibilities. Techniques such as layering, brushing, and sgraffito can be used to create intricate patterns and visual effects. For example, a potter might use multiple layers of different colored glazes to achieve a depth and complexity that would not be possible with a single glaze application. The aesthetic qualities of the glaze contribute significantly to the overall appeal and perceived value of the earthenware beverage container.

In summary, the selection of glaze type is a critical consideration in the production of earthenware beverage containers. It impacts not only the aesthetic appeal but also the safety and functionality of the product. Lead-free glazes are essential for ensuring consumer health, while functional glazes provide impermeability and durability. The diverse range of decorative glazes allows for artistic expression and enhances the overall value of the mug. Consequently, careful attention to glaze formulation and application is paramount in the creation of high-quality and safe coffee mugs.

4. Thermal Properties

Thermal properties play a crucial role in the performance and user experience of earthenware beverage containers. The inherent ability of earth materials to conduct, retain, and radiate heat directly influences the temperature of the liquid contents and the external surface temperature of the mug, affecting usability and overall satisfaction.

- Heat Capacity and Retention

Heat capacity, the measure of energy required to raise the temperature of a substance, is a key factor. Earthenware generally exhibits moderate heat capacity, enabling it to absorb heat from the beverage and subsequently release it slowly. This slow release maintains the drink’s temperature for a longer period compared to materials with lower heat capacity, such as thin glass or metal. However, compared to materials like insulated stainless steel, the retention is less effective, leading to a gradual cooling of the contents. The thickness of the vessel wall also influences retention; thicker walls provide greater insulation and extended heat maintenance.

- Thermal Conductivity

Thermal conductivity dictates the rate at which heat transfers through the material. Earthenware’s relatively low thermal conductivity means that heat does not readily dissipate through the mug walls. This characteristic is advantageous as it prevents excessive heat transfer to the user’s hand, allowing the mug to be held comfortably even when filled with hot liquid. Conversely, rapid heat transfer to the handle is also undesirable, and design considerations, such as a hollow handle or a handle made of a material with even lower thermal conductivity, mitigate this issue.

- Thermal Shock Resistance

Thermal shock resistance is the ability of a material to withstand sudden temperature changes without cracking or fracturing. Earthenware, due to its inherent composition and manufacturing process, can be susceptible to thermal shock, especially if not preheated or if exposed to extreme temperature variations. Rapid transition from a cold environment to a hot liquid can induce stress within the material, leading to micro-cracks or, in severe cases, catastrophic failure. The type of earth used, the firing temperature, and the glaze formulation all contribute to the overall thermal shock resistance of the mug.

- Surface Temperature and User Comfort

The thermal properties of the earth directly affect the surface temperature of the mug. While low thermal conductivity prevents excessive heat transfer, the external surface still warms up when filled with hot liquid. The temperature gradient between the liquid and the external surface depends on the material’s thickness, the ambient temperature, and the liquid’s temperature. Designs often incorporate features to enhance user comfort, such as strategically placed handles that minimize direct contact with the hottest areas or textured surfaces that provide a better grip and reduce the perception of heat.

The interplay of these thermal properties significantly influences the practical use and perceived quality of earthenware beverage containers. By understanding and manipulating these characteristics through careful material selection, design, and manufacturing processes, artisans can create mugs that effectively retain heat, provide a comfortable user experience, and withstand the rigors of daily use. The selection of a mug should therefore consider the user’s specific needs and preferences, balancing heat retention capabilities with thermal shock resistance and overall comfort.

5. Handcrafted Variation

Handcrafted variation represents a significant component of earthenware beverage containers, influencing both their aesthetic value and functional characteristics. The manual production process, inherent in the creation of such items, leads to unique attributes distinguishable from mass-produced counterparts. This variation stems from multiple factors, including the potter’s individual technique, the subtle inconsistencies in raw materials, and the nuances of the firing process. For example, two mugs crafted from the same batch of clay by the same artisan may exhibit slight differences in size, shape, glaze application, or surface texture. These deviations are not necessarily indicative of flaws but rather hallmarks of the human element in the manufacturing process. The importance of handcrafted variation lies in its contribution to the uniqueness and individuality of each piece.

The impact of handcrafted variation extends beyond mere aesthetics. Discrepancies in wall thickness, for instance, can affect thermal properties, influencing the rate at which the beverage cools. Slight imperfections in the glaze can alter the surface texture, impacting the tactile experience. Furthermore, the subtle variations in form and dimension can influence the comfort and ergonomics of the mug. Artisans may intentionally incorporate specific variations to enhance the aesthetic appeal or functional performance of their creations. The intentional introduction of texture, for example, can provide a more secure grip, while the application of unique glaze patterns can transform a utilitarian object into a work of art. Understanding these variations is crucial for appreciating the value and artistry inherent in handcrafted objects.

In conclusion, the presence of handcrafted variation in earthenware beverage containers is a defining characteristic that distinguishes them from mass-produced alternatives. This variation arises from the manual production process and contributes to the uniqueness, aesthetic appeal, and functional nuances of each piece. Recognizing and appreciating these variations is essential for understanding the inherent value and artistry of handcrafted objects, and allows consumers to make more informed choices based on their individual preferences and aesthetic sensibilities.

6. Artisanal Heritage

Earthenware beverage containers possess a tangible link to artisanal heritage, representing a continuity of craft traditions spanning centuries. The techniques employed in their creation, from the selection and preparation of raw materials to the shaping, firing, and glazing processes, often reflect localized knowledge and practices passed down through generations of artisans. This heritage imbues each piece with a cultural significance that transcends mere utilitarian function. The forms, patterns, and decorative motifs employed can often be traced back to specific geographic regions or historical periods, providing insight into the aesthetic preferences and cultural values of past societies. For example, the distinctive cobalt blue designs on Delftware, a type of tin-glazed pottery originating from the Netherlands, represent a direct connection to the 17th-century Dutch Golden Age. Similarly, the intricate floral patterns on traditional Japanese pottery reflect the influence of Zen Buddhism and the appreciation of natural forms. The preservation and perpetuation of these artisanal traditions are essential for maintaining cultural diversity and safeguarding valuable knowledge.

The importance of artisanal heritage in the context of earthenware beverage containers is multifaceted. First, it ensures the survival of traditional crafts and skills, preventing their extinction in an increasingly industrialized world. Second, it promotes sustainable practices, as many traditional techniques utilize locally sourced materials and environmentally friendly production methods. Third, it enhances the economic viability of rural communities, providing artisans with a means of livelihood and contributing to regional development. The resurgence of interest in handcrafted goods has led to a renewed appreciation for the value of artisanal heritage, with consumers increasingly seeking out unique, high-quality products that reflect a connection to tradition. This trend has spurred the growth of artisan cooperatives and small-scale pottery workshops, providing opportunities for artisans to showcase their skills and connect with a wider market. The revival of traditional pottery techniques in Oaxaca, Mexico, for instance, has revitalized local economies and preserved a rich cultural legacy.

In conclusion, the connection between artisanal heritage and earthenware beverage containers is profound and multifaceted. It represents a continuity of craft traditions, promotes sustainable practices, and enhances the economic viability of rural communities. Recognizing and valuing this heritage is essential for preserving cultural diversity and safeguarding valuable knowledge. The challenges associated with maintaining these traditions in the face of globalization and industrialization underscore the importance of supporting artisan initiatives and promoting consumer awareness of the value of handcrafted goods. The appreciation of artisanal heritage extends beyond the aesthetic realm, acknowledging the social, economic, and environmental benefits associated with these time-honored practices.

7. Durability Assessment

Durability assessment of earthenware beverage containers is a critical process for both manufacturers and consumers. It determines the lifespan, reliability, and overall value of these items, ensuring they can withstand the stresses of daily use. A thorough assessment considers various factors that contribute to the mug’s ability to resist damage and maintain its structural integrity over time.

- Resistance to Thermal Shock

Thermal shock resistance refers to the ability of the material to withstand sudden temperature changes without cracking or fracturing. This is particularly important for items that are frequently subjected to hot and cold liquids. To assess thermal shock resistance, a mug may undergo repeated cycles of rapid heating and cooling, followed by visual inspection for any signs of damage. For example, a mug may be submerged in ice water immediately after being filled with boiling water. The absence of cracks after several cycles indicates a higher level of thermal shock resistance.

- Chip Resistance

Chip resistance is a measure of the mug’s ability to withstand impacts without chipping or breaking. This is especially relevant for the rim and handle, which are the most vulnerable areas. Chip resistance can be evaluated through drop tests, where the mug is dropped from a specified height onto a hard surface. The severity of any chipping or damage is then assessed. Mugs intended for commercial use, such as in restaurants or cafes, often undergo more rigorous chip resistance testing to ensure they can withstand the demands of a high-traffic environment.

- Glaze Integrity

The integrity of the glaze coating is essential for both aesthetic appeal and functional performance. A durable glaze should resist scratching, staining, and crazing (the formation of fine cracks on the surface). Glaze integrity can be assessed through scratch tests, chemical resistance tests, and visual inspection. For example, a knife may be used to lightly scratch the surface of the glaze to determine its hardness and resistance to abrasion. Exposure to acidic substances, such as lemon juice or vinegar, can also reveal any vulnerabilities in the glaze coating.

- Structural Integrity

Structural integrity encompasses the overall stability and strength of the mug, ensuring it can withstand the stresses of daily handling and use. This can be assessed through weight-bearing tests and visual inspection for any signs of warping, cracking, or other structural defects. A weight-bearing test might involve filling the mug with a specific volume of liquid and then applying additional weight to the handle or body to determine its load-bearing capacity. Consistent use can overtime reveal any structural issues.

These facets of durability assessment, when applied to earthenware beverage containers, provide valuable insights into their expected lifespan and suitability for various applications. By carefully evaluating thermal shock resistance, chip resistance, glaze integrity, and structural integrity, both manufacturers and consumers can make informed decisions regarding the quality and longevity of these commonly used items. Understanding the nuances of these tests allows for a more objective evaluation beyond mere aesthetic appreciation.

Frequently Asked Questions

The following addresses common inquiries and misconceptions surrounding earthenware beverage containers, offering clarity on their usage, care, and properties.

Question 1: Are all clay coffee mugs safe for consuming hot beverages?

Not all are inherently safe. The glaze utilized must be lead-free and food-safe certified to prevent the leaching of harmful substances into the beverage. Purchase from reputable sources and verify compliance with relevant safety standards.

Question 2: How does one prevent clay coffee mugs from cracking due to thermal shock?

Sudden temperature changes induce stress. Preheat the item with warm water before introducing hot liquids. Avoid abrupt transitions from refrigerator to microwave or oven.

Question 3: What is the best method for cleaning clay coffee mugs to avoid damage?

Hand washing with a non-abrasive sponge and mild detergent is generally recommended. While some are dishwasher safe, the high heat and harsh detergents can degrade the glaze over time.

Question 4: Can clay coffee mugs be used in a microwave oven?

Microwave compatibility varies. Metallic glazes can cause arcing and damage. Verify microwave suitability with the manufacturer or look for indications on the item itself.

Question 5: How does the material of a clay coffee mug affect its heat retention capabilities?

Earthenware, stoneware, and porcelain exhibit different heat retention properties. Porcelain generally offers superior heat retention due to its density and vitrification. The thickness of the mug walls also plays a role.

Question 6: What are the environmental considerations associated with clay coffee mug production and disposal?

Production involves energy-intensive firing processes and resource extraction. Sustainable practices include using recycled materials, minimizing waste, and opting for locally sourced clay. Proper disposal methods are essential to minimize environmental impact.

In summary, responsible selection, usage, and disposal practices are essential for maximizing the benefits and minimizing the risks associated with earthenware beverage containers.

The subsequent section will explore emerging trends and innovations in the production and design of these items.

Concluding Observations on Earthenware Beverage Containers

The preceding exploration has illuminated the multifaceted nature of vessels designed for hot beverage consumption. From their material composition and firing temperatures to glaze types, thermal properties, and artisanal heritage, these items embody a complex interplay of factors that influence their functionality, aesthetic appeal, and cultural significance. The importance of durability assessment and responsible usage practices has also been emphasized, underscoring the need for informed consumer choices.

As the pursuit of sustainable and ethically sourced goods continues to gain momentum, the future of earthenware beverage containers hinges on innovative production methods, responsible material sourcing, and a renewed appreciation for the value of handcrafted traditions. Continued research and development in these areas will be crucial for ensuring the longevity and relevance of these enduring objects. The responsibility rests on manufacturers, artisans, and consumers alike to uphold the standards of quality, safety, and environmental stewardship that define the legacy of clay-based craftsmanship.

![Best 8 Ounce Travel Coffee Mug [Portable Size!] Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Best 8 Ounce Travel Coffee Mug [Portable Size!] | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://deacoffee.com/wp-content/uploads/2025/06/th-2621-300x200.jpg)

![Best Campfire Coffee Mugs [Outdoor Gear] Reviews Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Best Campfire Coffee Mugs [Outdoor Gear] Reviews | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://deacoffee.com/wp-content/uploads/2025/06/th-2033-300x200.jpg)