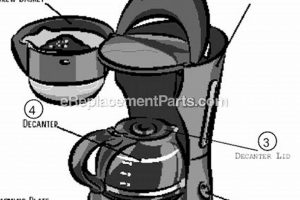

A glass or thermal container specifically designed to receive brewed coffee from an automated coffee machine. This receptacle often features a handle and pouring spout, facilitating the dispensing of the prepared beverage. A typical usage involves placing the container under the drip spout of a coffee machine before initiating the brewing cycle.

The use of a designated vessel to collect brewed coffee ensures convenient serving and maintains the beverage’s temperature. Historically, such containers have evolved from simple pitchers to sophisticated thermal designs capable of preserving heat for extended periods. This evolution addresses the need for both ease of use and preservation of coffee quality.

The subsequent sections will delve into the different types available, the materials used in their construction, factors to consider when selecting a replacement, proper maintenance techniques, and potential compatibility issues with various coffee machine models.

Tips Regarding Coffee Machine Vessels

Considerations for maximizing the lifespan and performance of receptacles used with automated coffee machines are detailed below.

Tip 1: Ensure compatibility. Prior to acquiring a replacement, verify that the model number corresponds with the specifications of the coffee machine to prevent leakage or malfunction.

Tip 2: Prioritize material selection. Thermal models offer superior temperature retention compared to glass, but require different cleaning protocols.

Tip 3: Implement regular cleaning procedures. Mineral buildup from hard water can impair thermal efficiency and affect taste. Use a descaling solution periodically.

Tip 4: Avoid abrasive cleaners. Scouring pads and harsh chemicals can scratch glass surfaces, leading to cloudiness and potential structural weakness.

Tip 5: Handle with care. Glass is susceptible to thermal shock. Avoid sudden temperature changes, such as immediately immersing a hot vessel in cold water.

Tip 6: Inspect for damage. Regularly check for cracks, chips, or fractures, particularly around the handle and spout, as these can compromise structural integrity and pose a safety hazard.

Tip 7: Consider capacity. Select a size that aligns with typical brewing volumes to minimize waste and optimize efficiency.

Adhering to these recommendations will contribute to extended usability, consistent performance, and the preservation of coffee quality.

The subsequent section will present a concluding overview of the information presented.

1. Material Composition

The selection of materials significantly influences the performance, durability, and safety of receptacles intended for use with automated coffee machines. The composition directly affects thermal properties, chemical inertness, and structural integrity.

- Glass (Borosilicate)

Borosilicate glass, commonly employed, exhibits high thermal shock resistance, mitigating the risk of fracture due to rapid temperature changes. Its inert nature prevents the leaching of chemicals into the brewed coffee, preserving flavor integrity. However, glass is susceptible to breakage upon impact and offers limited thermal retention compared to alternative materials.

- Stainless Steel (Thermal)

Double-walled stainless steel constructions, often with vacuum insulation, provide superior thermal retention, maintaining coffee temperature for extended periods. Stainless steel is durable and resistant to corrosion. However, it is opaque, preventing visual assessment of coffee level. Additionally, some individuals may perceive a metallic taste, though this is typically associated with lower-grade alloys.

- Plastic (BPA-Free)

Certain components, such as handles and lids, may incorporate BPA-free plastics. These materials are lightweight and cost-effective. The absence of BPA reduces the risk of endocrine disruption. However, plastic is less durable than glass or stainless steel and can potentially absorb odors or flavors over time.

- Ceramic

While less common, ceramic offers aesthetic appeal and good thermal properties. Ceramic is inert and does not impart flavors to coffee. However, it is more brittle than glass and stainless steel, increasing the risk of breakage.

The choice of material composition represents a critical trade-off between thermal performance, durability, cost, and aesthetic considerations. Manufacturers must carefully balance these factors to meet consumer expectations for both functionality and safety.

2. Thermal Retention

Thermal retention is a crucial attribute directly influencing the functionality and user satisfaction associated with vessels designed for automated coffee machines. Its effectiveness determines the duration for which brewed coffee maintains an optimal serving temperature, impacting taste and overall enjoyment.

- Material Conductivity

The inherent thermal conductivity of the vessel’s material dictates the rate of heat transfer. Materials with low thermal conductivity, such as insulated stainless steel, minimize heat loss to the surrounding environment, resulting in extended temperature maintenance. Conversely, materials like glass exhibit higher thermal conductivity, leading to more rapid cooling of the coffee.

- Insulation Techniques

The implementation of insulation techniques further enhances thermal retention. Vacuum insulation, commonly employed in double-walled stainless steel constructions, creates a void devoid of air, thereby impeding heat transfer through conduction and convection. Other techniques include the use of insulating layers or coatings to minimize radiative heat loss.

- Lid Design and Sealing

The design and sealing mechanism of the lid significantly contribute to thermal performance. A tightly sealed lid prevents heat escape through convection and minimizes evaporative cooling. The material of the lid, its fit, and the presence of gaskets or seals all influence its effectiveness in retaining heat.

- External Environmental Factors

External environmental factors, such as ambient temperature and air currents, exert a considerable influence on thermal retention. A vessel placed in a cold environment will experience a faster rate of heat loss compared to one situated in a warmer setting. Similarly, exposure to drafts or moving air can accelerate cooling.

The interplay of material properties, insulation methodologies, lid design, and environmental conditions collectively determines the thermal retention capabilities. Consequently, selecting a vessel that addresses these factors is paramount for consumers seeking to preserve the temperature and palatability of their brewed coffee over extended periods.

3. Capacity Volume

The capacity volume of a container used with automated coffee machines directly dictates the quantity of brewed coffee produced in a single brewing cycle. The intended use case for the coffee maker determines the appropriate capacity. Smaller households or individuals typically require receptacles with lower volumes, while larger offices or frequent entertainers necessitate larger capacities.

Selecting a volume that aligns with typical consumption patterns minimizes waste. For example, consistently brewing only half the capacity of an oversized receptacle results in prolonged exposure of the coffee to air, potentially affecting its flavor and temperature. Conversely, a volume insufficient for demand necessitates multiple brewing cycles, increasing energy consumption and user inconvenience. Real-world examples include single-serve coffee makers utilizing receptacles with a capacity of a single cup, and commercial coffee machines employing larger containers with multi-liter capacities.

The interrelationship between capacity volume and brewing frequency represents a key consideration for efficient operation. Manufacturers offer a range of volumes to accommodate diverse user needs. An informed selection optimizes resource utilization and ensures a consistent supply of freshly brewed coffee.

4. Compatibility

The concept of compatibility is paramount when addressing receptacles designed for automated coffee machines. Proper alignment between the vessel and the machine ensures seamless operation, prevents functional impairments, and avoids potential safety hazards. The following considerations outline the key facets of achieving this crucial compatibility.

- Dimensional Conformance

Precise dimensional conformance is critical for proper fit and function. The height, base diameter, and spout alignment must correspond precisely to the coffee machine’s specifications. Deviations can result in leakage, overflow, or failure of the brewing cycle. An instance of dimensional non-conformance is a receptacle too tall, obstructing the machine’s upper components, or a base diameter too small, leading to instability.

- Valve Actuation Mechanism

Many coffee machines incorporate a valve actuation mechanism that engages when the receptacle is correctly positioned. This mechanism allows the brewed coffee to flow. An incompatible container may fail to activate this valve, resulting in coffee not dispensing. The design and placement of the activating component on the vessel must precisely match the machine’s requirements.

- Thermal Sensor Interaction

Certain advanced coffee machines employ thermal sensors that monitor the temperature of the receptacle or the brewed coffee. These sensors regulate brewing parameters or activate safety features. An incompatible container may interfere with sensor readings, leading to inaccurate temperature control or system malfunctions. The material and shape of the receptacle must allow for accurate sensor readings.

- Material Composition and Chemical Reactivity

The material composition of the vessel must be compatible with the brewing process. Certain materials may react with the hot coffee, altering its flavor or leaching harmful chemicals. Incompatible materials can also degrade over time due to exposure to heat and moisture. The selected material should be inert, heat-resistant, and food-safe, ensuring the integrity of the brewed coffee and the safety of the user.

The aforementioned elements underscore the significance of confirming compatibility between automated coffee machines and their corresponding vessels. Neglecting these aspects can lead to operational inefficiencies, compromised coffee quality, and potential safety risks. Consulting the manufacturer’s specifications or utilizing designated replacement parts is advisable to ensure optimal performance.

5. Ergonomic Design

Ergonomic design principles are fundamentally linked to the utility and safety of containers designed for use with automated coffee machines. The integration of ergonomic considerations directly impacts the user’s ability to handle and manipulate the vessel, influencing pouring precision, minimizing strain, and reducing the risk of accidental spills or injuries. The following facets highlight key ergonomic considerations.

- Handle Design

Handle design encompasses factors such as shape, material, and grip surface. An ergonomically designed handle should facilitate a secure and comfortable grip, minimizing hand and wrist strain during pouring. Examples include contoured handles that conform to the natural curvature of the hand, and the utilization of non-slip materials to enhance grip security. An improperly designed handle can lead to awkward wrist angles and increased effort, potentially resulting in spills or muscle fatigue.

- Weight Distribution

Even weight distribution, both when empty and full, is crucial for stability and control. A vessel with uneven weight distribution can be prone to tipping, increasing the risk of spills and potential burns. An example of proper weight distribution involves a low center of gravity, providing a stable base of support. Conversely, a top-heavy design can make pouring precarious, particularly when the vessel is full.

- Spout Geometry

Spout geometry significantly impacts pouring precision and control. A well-designed spout should facilitate a smooth, drip-free pour, minimizing splashing and wasted coffee. Factors such as spout angle, width, and lip design contribute to its effectiveness. A poorly designed spout can result in erratic pouring streams, leading to spills and an untidy serving experience.

- Overall Form Factor

The overall form factor encompasses the shape, size, and proportions of the vessel. An ergonomically optimized form factor should be easy to grasp and maneuver, minimizing the risk of awkward handling or accidental bumps. Streamlined designs with rounded edges can enhance grip comfort and reduce the likelihood of snagging on objects. Bulky or awkwardly shaped designs can increase the risk of spills and user fatigue.

The ergonomic aspects outlined above collectively contribute to the overall usability and safety of vessels used with automated coffee machines. Adherence to these principles promotes a comfortable and efficient user experience, mitigating potential risks and enhancing the enjoyment of the brewed beverage. Considerations of material, form, and function are interwoven in the effective design of these often-overlooked components.

6. Cleaning Ease

The ease with which a receptacle for a coffee machine can be cleaned directly impacts its longevity and the overall quality of the brewed coffee. Residue buildup, primarily from coffee oils and mineral deposits, can negatively affect taste and contribute to unsanitary conditions. Therefore, cleaning ease is not merely a convenience but a critical performance characteristic. For instance, a design featuring a narrow opening can impede thorough cleaning, fostering the accumulation of residue and necessitating specialized brushes or tools. A real-world example is a thermal design with complex internal components, increasing the potential for trapped residue and diminishing long-term performance.

Practical considerations surrounding cleaning include dishwasher compatibility and the accessibility of internal surfaces. Dishwasher-safe designs reduce manual labor, while easily accessible surfaces permit effective scrubbing and rinsing. Materials prone to staining or difficult-to-remove deposits, such as certain plastics or improperly sealed glass, reduce cleaning effectiveness. In practical application, a stainless-steel interior generally offers superior resistance to staining and easier removal of mineral deposits than a plastic alternative. The shape and construction of the pouring spout are also important, since residue can accumulate in tight curves.

In summary, cleaning ease is an integral design consideration, influencing both hygiene and product lifespan. Choosing designs that facilitate efficient and thorough cleaning mitigates the buildup of contaminants, preserves the integrity of the brewed coffee, and enhances the long-term value of the vessel. Challenges lie in balancing cleaning ease with other performance requirements, such as thermal retention and durability.

Frequently Asked Questions

The following addresses common inquiries concerning receptacles designed for automated coffee machines, providing concise and informative responses.

Question 1: What materials are considered optimal for thermal preservation?

Double-walled stainless steel, typically with a vacuum-sealed cavity, offers superior thermal retention compared to glass or single-walled constructions. The vacuum inhibits heat transfer through conduction and convection, maintaining temperature for an extended duration.

Question 2: How does the vessel’s shape affect brewing performance?

The shape can influence the rate of heat dissipation and the evenness of coffee distribution during brewing. Taller, narrower designs may exhibit less heat loss, while wider bases provide greater stability. The internal shape should promote uniform coffee saturation.

Question 3: What cleaning agents are generally recommended for maintenance?

Mild dish soap and warm water are suitable for routine cleaning. For mineral deposit removal, a solution of white vinegar and water can be effective. Abrasive cleaners should be avoided as they can damage surfaces.

Question 4: Is it possible to use a substitute if the original receptacle is unavailable?

While a substitute may be employed, dimensional and functional compatibility must be ensured. Improper fit can lead to leaks or operational malfunctions. Verifying the manufacturer’s specifications is crucial.

Question 5: What indicators suggest that a replacement is necessary?

Visible cracks, chips, or fractures necessitate immediate replacement due to potential safety hazards. Loss of thermal insulation effectiveness also indicates a need for replacement.

Question 6: How does water quality impact the lifespan?

Hard water accelerates mineral deposit buildup, reducing thermal efficiency and potentially causing clogs. Regular descaling with appropriate solutions mitigates these effects, extending the lifespan.

Proper selection and maintenance are paramount for optimal performance and longevity.

The subsequent section will provide resources for sourcing replacements.

Concluding Remarks

This exploration has detailed the critical attributes of the receptacle used with automated coffee machines, encompassing material composition, thermal retention, capacity volume, compatibility, ergonomic design, and cleaning ease. Understanding these factors enables informed decision-making when selecting or replacing this essential component. Failure to consider these elements may result in suboptimal brewing performance, compromised beverage quality, and reduced equipment longevity.

Therefore, careful evaluation of these characteristics is not merely a matter of convenience, but a fundamental aspect of ensuring a reliable and satisfactory coffee brewing experience. Continued adherence to proper maintenance procedures further maximizes the lifespan and enhances the overall value of the receptacle. Consideration should be given to advancements in material science and design, as these innovations will undoubtedly shape the future of this indispensable accessory.

![Best Programmable 12 Cup Coffee Maker [Guide] The Ultimate Coffee Guide: Types, Brewing Methods & Best Beans Best Programmable 12 Cup Coffee Maker [Guide] | The Ultimate Coffee Guide: Types, Brewing Methods & Best Beans](https://deacoffee.com/wp-content/uploads/2026/02/th-300x200.jpg)