The documentation accompanying a specific brand of automated coffee brewing equipment outlines the procedures for its proper operation and maintenance. These guidelines typically include steps for initial setup, daily brewing processes, cleaning schedules, and troubleshooting common issues.

Adhering to the manufacturer’s provided documentation ensures optimal performance, consistent beverage quality, and extends the lifespan of the appliance. Historically, printed manuals were the primary source, but contemporary methods often incorporate digital formats accessible via online platforms or mobile applications. Following recommended procedures also helps to mitigate potential safety hazards and maintain warranty validity.

The subsequent sections will delve into specific aspects such as initial setup, the brewing process, cleaning protocols, and methods for resolving common operational errors related to this type of coffee-making device.

Operational Guidance

This section provides essential recommendations for maximizing the performance and longevity of the specific automated coffee brewer.

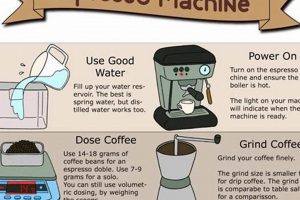

Tip 1: Priming the Tank: Prior to initial use, ensure the internal hot water tank is fully primed. This prevents element burnout and ensures immediate brewing capability. Fill the reservoir according to the manufacturer’s specifications and allow sufficient time for the unit to heat and stabilize.

Tip 2: Water Quality Considerations: Employ filtered water. Mineral deposits from untreated water can accumulate within the system, reducing efficiency and potentially causing damage. Periodic descaling, as outlined in the documentation, is recommended even with filtered water usage.

Tip 3: Correct Filter Usage: Utilize the recommended filter type and size. Improperly sized or incorrect filter types may lead to overflow or incomplete brewing. Ensure the filter is correctly positioned within the brew funnel before initiating the brewing cycle.

Tip 4: Grinding Consistency: Implement a medium-grind coffee. Too fine a grind may result in a bitter, over-extracted brew, while a coarse grind may produce a weak, under-extracted result. Adjust grinder settings to achieve optimal extraction.

Tip 5: Regular Cleaning Schedule: Adhere to the prescribed cleaning schedule. Mineral buildup and coffee oil residue can negatively impact flavor and performance. Follow the descaling procedures outlined in the manual, utilizing the recommended cleaning solutions.

Tip 6: Temperature Maintenance: If equipped, ensure the warmer plate is functioning correctly. Maintaining a consistent temperature is crucial for preserving the quality of the brewed coffee. Avoid prolonged periods of holding brewed coffee on the warmer to prevent bitterness.

Tip 7: Prompt Troubleshooting: Address any irregularities promptly. Unusual noises, slow brewing, or temperature fluctuations may indicate an underlying issue. Consult the troubleshooting section of the documentation for guidance.

Consistent adherence to these guidelines will contribute to optimal brewing results and extend the lifespan of the coffee-making appliance.

The concluding section will summarize key recommendations and offer final thoughts on operating the coffee brewing apparatus.

1. Initial setup procedure

The initial setup procedure, as detailed within the documentation for automated coffee brewing equipment, directly influences the operational lifespan and beverage quality of the appliance. The process transcends a simple power connection and necessitates specific steps for optimal performance.

- Tank Priming and Water Introduction

The filling and priming of the internal hot water tank constitute a critical first step. Failure to adequately prime the tank, according to specified procedures, can result in heating element damage and delayed operational readiness. This step is especially critical in plumbed-in models, where water pressure must be regulated. The manufacturer’s documentation provides precise guidelines for water level and initial heating duration, preventing dry starts and ensuring consistent water temperature for subsequent brewing cycles.

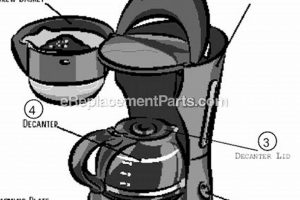

- Filter and Funnel Assembly

The correct assembly of the filter and brew funnel directly impacts the extraction process. Incorrect filter placement can lead to overflows, uneven saturation of coffee grounds, and inconsistent brew strength. The documentation provides visual aids and detailed instructions on properly seating the filter within the funnel and ensuring compatibility with the specific model. This step ensures efficient water flow through the grounds and prevents sediment from entering the brewed coffee.

- Initial Cleaning Cycle

Many manufacturers recommend running an initial cleaning cycle with water to remove any residual manufacturing oils or debris from the system. This cycle purges the internal components, ensuring a clean taste in the first batch of brewed coffee. Failure to perform this initial cleaning may result in an off-taste or odor in subsequent brews. The documentation specifies the volume of water required for this cleaning cycle and any recommended cleaning agents, if applicable.

- Power Connection and System Test

The final step involves connecting the unit to a power source and verifying its functionality. The documentation will specify the required voltage and any necessary grounding precautions. After powering on, the user should observe the system for any error messages or unusual noises. The brewing of a test batch, following the documentation’s instructions, confirms the system’s operational status and verifies proper water heating and dispensing.

These elements of the initial setup procedure are interdependent and collectively contribute to the reliable operation of the coffee brewing equipment. Adherence to these guidelines, as detailed within the documentation, directly minimizes the risk of operational errors and maximizes the potential for consistently high-quality brewed coffee.

2. Water reservoir filling

The water reservoir filling process, as delineated in the documentation accompanying automated coffee brewing equipment, represents a critical prerequisite for proper operation. Deviations from the specified filling parameters can initiate a cascade of adverse effects, ranging from compromised brewing performance to potential appliance damage. The instructions provide specific guidance concerning water level limits, water quality considerations, and the sequencing of the filling process, all of which directly impact the final beverage produced. Insufficient water levels, for instance, can lead to incomplete brewing cycles, while overfilling may cause overflow and system malfunction. The manufacturer’s documentation explicitly outlines these potential consequences, reinforcing the importance of adherence to the recommended procedures.

Beyond operational considerations, the type of water introduced into the reservoir directly affects the longevity of the brewing apparatus. Mineral-rich water sources contribute to scale buildup within the heating elements and internal plumbing, reducing efficiency and potentially leading to premature failure. The documentation often recommends the use of filtered water or provides guidance on descaling procedures to mitigate these effects. Furthermore, the instructions address the proper method for filling the reservoir, particularly concerning models with direct water line connections. Incorrect connections can cause leaks, water pressure issues, or contamination of the water supply. The documentation serves as a reference for ensuring a safe and reliable water supply to the brewing equipment.

In summary, the proper filling of the water reservoir, as guided by the equipment’s documentation, forms a foundational element of its successful operation. Adherence to the specified guidelines ensures optimal brewing performance, extends the lifespan of the appliance, and mitigates the risk of operational malfunctions. By following these procedures, users can reliably produce high-quality brewed coffee while minimizing the potential for costly repairs or replacements. The documented instructions serve as an essential resource for achieving consistent and trouble-free operation.

3. Filter type specification

The filter type specification, as outlined within the documentation accompanying automated coffee brewing equipment, plays a crucial role in the overall brewing process. Adherence to these specifications directly influences beverage quality, equipment performance, and operational safety. The manufacturer’s provided documentation is the authoritative source for determining the correct filter type.

- Filter Material and Pore Size

The filter material and pore size dictates the rate of water flow and the retention of coffee grounds. Paper filters, commonly specified in the documentation, remove sediment and oils, producing a cleaner-tasting brew. The pore size ensures consistent water flow and prevents over-extraction or under-extraction of the coffee. Deviations from the prescribed material or pore size can lead to undesirable flavors or clogging of the brewing apparatus.

- Filter Dimensions and Shape

Filter dimensions and shape are critical for proper fit within the brew funnel. The manufacturer’s documentation explicitly details the correct filter size (e.g., basket, cone) and shape, ensuring a secure fit and preventing overflow or bypass of coffee grounds. Incorrect dimensions may result in uneven saturation, inconsistent brew strength, and potential damage to the equipment.

- Filter Bleaching and Chemical Composition

The filter’s bleaching process and chemical composition affect the taste and aroma of the brewed coffee. The documentation may specify chlorine-free or unbleached filters to minimize any residual chemicals from leaching into the coffee. Such specifications cater to consumer preferences and adhere to safety standards. The use of unapproved filter types, especially those with unknown chemical compositions, can introduce unwanted flavors and pose potential health risks.

- Filter Compatibility with Brewing Equipment

The filter type must be compatible with the design of the brewing equipment. Documentation specifies whether the equipment necessitates proprietary filters or if generic alternatives are acceptable. The use of incompatible filters can compromise brewing efficiency, damage the equipment, and void warranties. Following the manufacturers specifications ensures that the chosen filter integrates seamlessly with the brewing process.

Filter specifications, as provided in the brewing equipment’s documentation, are not merely suggestions; they are critical parameters that govern the brewing process. By adhering to these specifications, users can consistently produce high-quality coffee while minimizing the risk of operational issues and equipment damage. The manufacturer’s instructions provide an essential guide for ensuring filter compatibility and achieving optimal brewing results.

4. Brewing cycle initiation

The commencement of the brewing cycle constitutes a pivotal step in the operation of automated coffee brewing equipment. The “bunn o matic coffee maker instructions” provide explicit guidelines on the correct procedure for initiating this cycle, thereby directly influencing the resultant beverage’s quality and consistency. Deviations from the manufacturer’s recommended procedures can lead to incomplete brewing, overflow issues, or equipment malfunction. For instance, incorrect button presses or improperly engaged switches may prevent the system from initiating the heating process, resulting in a cold or weak brew. The instructions serve as a safeguard against such operational errors.

The documented procedures address specific considerations relevant to different equipment models. Some units require pre-heating before initiating the brewing cycle. Others feature programmable timers, allowing for automated initiation at a pre-set time. The “bunn o matic coffee maker instructions” detail these model-specific nuances, ensuring that users correctly activate the brewing process according to their particular equipment. Moreover, the instructions typically include safety precautions, such as ensuring that the carafe is properly positioned before initiation to prevent spills and potential burns. Real-world examples, such as leaving the carafe askew, highlight the practical significance of adhering to these safety directives.

In conclusion, the brewing cycle initiation process is inextricably linked to the “bunn o matic coffee maker instructions.” These instructions serve as the definitive guide for achieving optimal brewing performance and ensuring safe operation. Understanding and adhering to the manufacturer’s recommendations minimizes the risk of operational errors, promotes consistent beverage quality, and protects the integrity of the coffee brewing equipment. The consistent theme throughout is that proper adherence to the brewing cycle initiation process guarantees successful and safe brewing process with a bann o matic coffee maker.

5. Regular cleaning protocols

Regular cleaning protocols, as detailed within the equipment’s documentation, are essential for the sustained operational efficiency and beverage quality of automated coffee brewing equipment. These protocols address the accumulation of mineral deposits, coffee oils, and other residues that impede performance and compromise taste. Adherence to these procedures, as described in the “bunn o matic coffee maker instructions,” is critical for maintaining the integrity of the system.

- Descaling Procedures

Descaling procedures involve the removal of mineral deposits, primarily calcium and magnesium carbonates, that accumulate within the heating elements and internal plumbing. The “bunn o matic coffee maker instructions” specify the frequency of descaling based on water hardness and the recommended descaling agents. Failure to regularly descale can lead to reduced heating efficiency, increased brewing time, and ultimately, equipment failure. For example, a hard water source necessitates more frequent descaling cycles to prevent mineral buildup from impeding water flow.

- Cleaning of Brewing Components

The brewing components, including the brew funnel, spray head, and carafe, require routine cleaning to remove coffee oils and grounds residue. The “bunn o matic coffee maker instructions” provide guidance on the appropriate cleaning solutions and methods for each component. Neglecting this aspect of the cleaning protocols can result in stale coffee flavors, clogs in the spray head, and unsanitary conditions within the brewing chamber. Improper cleaning solutions could also damage sensitive components.

- Sanitization Protocols

Sanitization protocols aim to eliminate bacterial growth and ensure hygienic conditions within the coffee brewing equipment. The “bunn o matic coffee maker instructions” outline the use of sanitizing agents or high-temperature cleaning cycles to achieve this objective. Sanitization is particularly important in commercial settings to prevent the spread of foodborne illnesses. Insufficient sanitation practices can result in the growth of mold or bacteria within the reservoir or brewing components, posing a health risk.

- Preventative Maintenance Checks

Regular cleaning protocols often include preventative maintenance checks, such as inspecting hoses, seals, and connectors for leaks or damage. The “bunn o matic coffee maker instructions” may provide a checklist of items to inspect during the cleaning process. Identifying and addressing minor issues early on can prevent more significant problems from developing, extending the lifespan of the equipment. For example, a cracked water line, if left unaddressed, could lead to a major leak and necessitate costly repairs.

The implementation of consistent cleaning protocols, as detailed within the “bunn o matic coffee maker instructions,” is not merely a matter of aesthetic cleanliness; it is an essential element of equipment maintenance and operational hygiene. Adherence to these procedures promotes optimal brewing performance, safeguards the integrity of the coffee brewing equipment, and mitigates the risk of health hazards. By prioritizing regular cleaning, users can ensure a consistent supply of high-quality coffee while preserving the longevity of their brewing apparatus.

6. Descaling frequency

Descaling frequency, a critical aspect of coffee brewer maintenance, is directly dictated by the “bunn o matic coffee maker instructions.” These instructions provide specific guidelines on how often the descaling process should be performed, tailored to the equipment model and considering factors impacting mineral buildup.

- Water Hardness and Descaling Intervals

Water hardness, measured by the concentration of minerals such as calcium and magnesium, directly influences the rate of scale accumulation within the brewing equipment. The “bunn o matic coffee maker instructions” typically include a chart or guidance on determining water hardness and correlating it with appropriate descaling intervals. For example, areas with “hard” water require more frequent descaling compared to regions with “soft” water. Failure to adjust descaling frequency based on water hardness can lead to reduced heating efficiency and potential equipment damage.

- Descaling Agent Specifications

The “bunn o matic coffee maker instructions” specify the type of descaling agent that is compatible with the equipment’s internal components. The wrong descaling agent can corrode or damage the heating elements and plumbing. For instance, using a harsh acid-based descaler on a system designed for a milder citric acid solution can result in premature failure. Adhering to the specified descaling agent ensures the safe and effective removal of mineral deposits without compromising the integrity of the machine.

- Descaling Procedure Steps

The “bunn o matic coffee maker instructions” provide step-by-step instructions on performing the descaling process. This includes details on solution concentration, fill levels, brewing cycles dedicated to descaling, and rinsing protocols. Deviating from these instructions can result in incomplete descaling, residual descaling agent affecting the taste of subsequent brews, or even damage to the equipment due to improper handling of descaling solutions.

- Consequences of Neglecting Descaling

The “bunn o matic coffee maker instructions” often highlight the consequences of neglecting regular descaling, which range from reduced brewing performance to equipment failure. Untreated scale buildup restricts water flow, reduces heating efficiency, and can ultimately cause the heating element to overheat and fail. The instructions may also include visual examples of scale buildup and its impact on system performance, providing a tangible reason for adhering to the recommended descaling schedule.

In summary, the descaling frequency, as defined by the “bunn o matic coffee maker instructions,” is not arbitrary but a calculated parameter based on water quality and equipment design. Adhering to these instructions ensures optimal brewing performance, extends the lifespan of the equipment, and maintains the quality of the brewed coffee. These instructions must be consulted to properly descaled the coffee maker to ensure maximum value. The instruction are very specific for a reason.

7. Troubleshooting guidance

Troubleshooting guidance, an integral component of the comprehensive documentation accompanying automated coffee brewing equipment, serves as a critical resource for resolving operational anomalies and maintaining optimal performance. These “bunn o matic coffee maker instructions” encompass a structured approach to diagnosing and rectifying common issues encountered during the lifespan of the appliance.

- Symptom Identification and Error Code Interpretation

The initial step in effective troubleshooting involves accurate symptom identification. The “bunn o matic coffee maker instructions” provide a catalog of common symptoms, such as slow brewing, unusual noises, or failure to heat, and correlate these symptoms with potential underlying causes. Moreover, many models display error codes that offer more specific diagnostic information. The documentation includes a comprehensive error code directory, enabling users to pinpoint the source of the malfunction. For example, an error code indicating “low water level” would prompt the user to verify the water reservoir level and inspect the water inlet valve.

- Component-Specific Diagnostic Procedures

Once a potential cause has been identified, the “bunn o matic coffee maker instructions” guide the user through component-specific diagnostic procedures. These procedures may involve visual inspections, electrical testing, or mechanical assessments. For instance, if the brewing cycle is slow, the documentation may instruct the user to inspect the spray head for clogs or to test the heating element’s resistance. Clear diagrams and step-by-step instructions facilitate these diagnostic tasks, minimizing the risk of misdiagnosis or further equipment damage.

- Corrective Action Recommendations and Safety Precautions

Upon pinpointing the source of the malfunction, the “bunn o matic coffee maker instructions” offer corrective action recommendations. These recommendations range from simple solutions, such as descaling the unit, to more complex procedures, such as replacing a faulty heating element. The documentation also emphasizes safety precautions, such as disconnecting the power supply before performing any repairs. Failure to heed these safety warnings can result in electrical shock or further equipment damage. For example, attempting to replace a heating element without first disconnecting the power poses a significant safety hazard.

- Escalation Pathways for Unresolved Issues

In situations where the user is unable to resolve the issue through the provided troubleshooting steps, the “bunn o matic coffee maker instructions” outline escalation pathways. This may involve contacting the manufacturer’s customer support line, seeking assistance from a qualified technician, or initiating a warranty claim. The documentation typically includes contact information and warranty details, ensuring that users have access to appropriate support channels. Attempting to perform unauthorized repairs can void the warranty and potentially cause further damage to the equipment.

The structured approach to troubleshooting, as defined by the “bunn o matic coffee maker instructions,” empowers users to resolve common operational issues efficiently and safely. By systematically identifying symptoms, diagnosing potential causes, and implementing corrective actions, users can minimize downtime and extend the lifespan of their coffee brewing equipment. The integration of clear diagrams, step-by-step instructions, and safety warnings ensures that troubleshooting tasks are performed correctly and without compromising personal safety or equipment integrity.

Frequently Asked Questions

This section addresses common inquiries regarding the operational procedures of automated coffee brewing equipment, drawing directly from the manufacturer’s documented instructions. The answers provided aim to clarify potential points of confusion and ensure proper equipment usage.

Question 1: What is the significance of priming the hot water tank during initial setup?

Priming the hot water tank is critical to prevent damage to the heating element. Without sufficient water, the element can overheat and fail prematurely. The manufacturer’s instructions provide specific guidance on the correct priming procedure.

Question 2: Why does the manufacturer emphasize the use of specific filter types?

The filter type, encompassing material and pore size, directly impacts brewing performance and beverage quality. Using non-specified filters can lead to overflow, uneven saturation, and inconsistent brew strength, according to the appliance’s documentation.

Question 3: How frequently should the equipment undergo descaling, and why is this important?

Descaling frequency depends on the water hardness in the user’s region. Mineral buildup restricts water flow, reduces heating efficiency, and can damage internal components. Refer to the provided instructions for determining the appropriate descaling schedule.

Question 4: What steps should be taken if the coffee brewing cycle is noticeably slower than usual?

Slow brewing cycles may indicate mineral buildup, a clogged spray head, or a malfunctioning heating element. Consult the troubleshooting section of the documentation for specific diagnostic and corrective procedures.

Question 5: Can any cleaning agent be used for routine maintenance, or are there specific recommendations?

The manufacturer’s instructions specify the recommended cleaning agents, emphasizing the avoidance of harsh chemicals that could damage internal components or leave residual flavors. Adherence to these recommendations is critical for preserving equipment integrity and beverage quality.

Question 6: What recourse is available if the equipment malfunctions despite adherence to the documented instructions?

If troubleshooting procedures fail to resolve the issue, consult the warranty information and contact the manufacturer’s customer support for assistance. Unauthorized repairs may void the warranty.

The information presented aims to provide clarification on commonly encountered operational questions. Consultation with the manufacturer’s documentation remains the primary source for comprehensive guidance.

The subsequent section will delve into advanced operational techniques.

Conclusion

The preceding analysis has detailed the importance of the documentation provided with automated coffee brewing equipment. Specific areas of focus included initial setup, water reservoir filling, filter type specifications, brewing cycle initiation, regular cleaning protocols, descaling frequency, and troubleshooting guidance. Each of these facets directly impacts the operational performance, longevity, and beverage quality of the device. Adherence to these directives ensures proper functionality and mitigates potential risks associated with improper use.

Therefore, thorough comprehension and consistent application of the “bunn o matic coffee maker instructions” are not merely recommendations, but essential prerequisites for maximizing the utility and lifespan of the equipment. Neglecting these guidelines can lead to diminished performance, equipment damage, and potential safety hazards. Responsible operation necessitates a commitment to following the manufacturer’s specifications and maintaining a proactive approach to equipment maintenance. The long-term benefits of proper adherence far outweigh the perceived inconvenience of diligent execution.

![Best Commercial Cold Press Coffee Maker [Guide & Reviews] The Ultimate Coffee Guide: Types, Brewing Methods & Best Beans Best Commercial Cold Press Coffee Maker [Guide & Reviews] | The Ultimate Coffee Guide: Types, Brewing Methods & Best Beans](https://deacoffee.com/wp-content/uploads/2026/02/th-87-300x200.jpg)