This kitchen appliance is engineered for brewing coffee, typically in commercial settings. It is designed for reliability and efficiency, offering a consistent output to meet the demands of restaurants, cafes, and other establishments where volume production is necessary.

Such a device streamlines beverage service, enhancing operational efficiency by producing large quantities of coffee quickly. Its historical context lies in the evolution of commercial coffee brewing technology, moving from manual methods to automated systems capable of maintaining consistent quality and reducing labor costs. The benefits include minimized waste, optimized brewing cycles, and durability for extended use in high-traffic environments.

Further discussion will detail specific models, their features, maintenance procedures, and considerations for selecting the appropriate unit for various business needs.

Operation and Maintenance Tips

Adhering to proper operational and maintenance procedures extends the lifespan and ensures the optimal performance of commercial coffee brewing equipment.

Tip 1: Water Quality Management: Consistent water quality is paramount. Regularly test and address water hardness and mineral content to prevent scale buildup within the machine. Implement a filtration system to remove impurities that can affect coffee taste and equipment longevity.

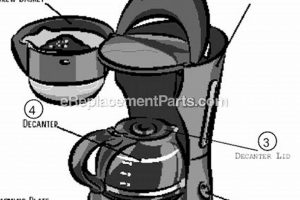

Tip 2: Daily Cleaning Regimen: Establish a daily cleaning schedule. Thoroughly rinse carafes and decanters immediately after use. Wipe down exterior surfaces and control panels to prevent residue accumulation.

Tip 3: Descaling Procedures: Periodically descale the equipment according to the manufacturer’s instructions. The frequency will depend on water hardness, but neglecting this step leads to decreased heating efficiency and potential component failure.

Tip 4: Basket and Filter Maintenance: Inspect brew baskets and filters regularly. Replace torn or damaged filters to prevent grounds from entering the finished product. Clean brew baskets thoroughly to remove coffee oils and residue.

Tip 5: Calibration and Settings: Periodically verify calibration settings such as brew time and water temperature. Deviations from optimal settings can impact coffee quality and consistency. Consult the user manual for proper adjustment procedures.

Tip 6: Preventive Maintenance Schedule: Implement a preventive maintenance schedule that includes inspection of hoses, seals, and heating elements. Address minor issues promptly to avoid major repairs.

Tip 7: Carafe Warming Plate Caution: Exercise caution when using the warming plate to ensure coffee does not scorch and impact the coffee pot’s integrity with prolonged exposure, use timers when available to limit warming duration.

Consistent adherence to these guidelines ensures optimal performance, extends equipment lifespan, and contributes to a consistent and high-quality coffee product.

The subsequent section will provide detailed troubleshooting advice for common issues and scenarios.

1. Commercial-grade brewing

Commercial-grade brewing signifies a standard of coffee preparation designed for high-volume, consistent output, and durability in demanding environments. Its application within the Avantco coffee maker is paramount to its intended use in restaurants, cafeterias, and other food service establishments. The following facets highlight the critical relationship between these two elements.

- Temperature Stability

Commercial-grade brewing necessitates precise temperature control throughout the brewing cycle. The Avantco coffee maker is engineered to maintain consistent water temperature, ensuring optimal extraction and a uniform flavor profile from batch to batch. Fluctuations in temperature can lead to under-extraction, resulting in sour or weak coffee, or over-extraction, causing bitterness.

- Brew Time Optimization

Brew time is a critical factor influencing coffee quality. Commercial-grade brewing equipment, such as the Avantco model, typically incorporates pre-set or adjustable brew time parameters. These settings allow operators to optimize the contact time between water and coffee grounds, achieving the desired strength and flavor characteristics while minimizing the risk of over or under-extraction. Incorrect brew times can negatively impact the final product, leading to customer dissatisfaction.

- Volume Consistency

Commercial-grade brewing demands the capability to produce consistent volumes of coffee. The Avantco coffee maker incorporates automated water level controls and pre-set volume settings, ensuring that each batch conforms to the specified quantity. This consistency is crucial for inventory management, cost control, and maintaining a consistent product offering. Variations in volume can disrupt operational efficiency and affect profitability.

- Robust Construction and Durability

Commercial-grade brewing equipment must withstand continuous use in demanding environments. The Avantco coffee maker is constructed with durable materials and components designed for longevity. This robust construction minimizes downtime, reduces maintenance costs, and ensures reliable performance. Inferior materials and construction can lead to frequent breakdowns and costly repairs, disrupting operations and impacting revenue.

The synergy between commercial-grade brewing principles and the Avantco coffee maker centers on delivering a reliable, consistent, and high-quality coffee product in demanding commercial settings. Understanding and adhering to these principles is essential for maximizing the value and longevity of the equipment.

2. Volume output capacity

The volume output capacity of an Avantco coffee maker directly influences its suitability for different commercial environments. This specification denotes the quantity of brewed coffee the machine can produce within a given timeframe, typically measured in gallons per hour or cups per hour. A higher volume output capacity enables the machine to meet the demands of establishments with significant coffee consumption, such as busy restaurants, large offices, or catering services. Conversely, a lower volume output may suffice for smaller cafes or break rooms with less frequent demand. Inadequate volume capacity relative to demand results in service delays, customer dissatisfaction, and potential revenue loss.

The design and engineering of the Avantco coffee maker are intrinsically linked to its volume output capacity. Larger models often incorporate multiple brewing chambers or enhanced heating elements to accelerate the brewing process and maintain consistent temperature across high-volume production cycles. These design features contribute to operational efficiency and prevent degradation in coffee quality when brewing large quantities. Proper maintenance and descaling are also essential to sustain optimal volume output, as mineral buildup can impede heating efficiency and reduce overall brewing capacity.

Understanding the volume output capacity of an Avantco coffee maker is crucial for informed purchasing decisions. Businesses must accurately assess their average and peak coffee consumption rates to select a model that aligns with their operational needs. Choosing a machine with insufficient capacity leads to inefficiencies and unmet demand, while overspecifying results in unnecessary capital expenditure. The capacity should also be considered in relation to the machine’s cycle time, which refers to the duration required to brew a complete batch. Efficient cycle times minimize wait times and maximize the throughput of the brewing process. Therefore, the intersection of volume output capacity and cycle time dictates the overall performance of the coffee maker within a specific commercial context.

3. Operational consistency

Operational consistency, concerning the Avantco coffee maker, denotes the machine’s ability to produce coffee of uniform quality and quantity across repeated brewing cycles. This factor is crucial in commercial settings where predictable output is paramount for customer satisfaction and cost control. The following facets detail the integral elements of this consistency.

- Temperature Regulation

Consistent water temperature is essential for optimal coffee extraction. The Avantco coffee maker’s thermostatic control mechanisms ensure the water remains within a narrow temperature range throughout the brewing process. Variations outside this range can lead to under-extraction (weak, sour coffee) or over-extraction (bitter, astringent coffee). Stable temperature regulation contributes directly to predictable flavor profiles.

- Brew Time Management

The duration of the brewing cycle significantly affects coffee strength and flavor. Consistent brew time, regulated by the machine’s internal timer, ensures that the water remains in contact with the coffee grounds for the appropriate length of time. Deviations in brew time can result in inconsistent extraction, impacting the coffee’s taste and aroma. Programmable settings enhance brew time management capabilities.

- Water Volume Control

The amount of water used in each brewing cycle must be consistent to maintain the desired coffee-to-water ratio. Automated water level controls within the Avantco coffee maker ensure precise water dispensing, contributing to predictable coffee strength and volume. Inconsistent water levels can lead to variations in coffee concentration and overall product quality.

- Component Reliability

The durability and consistent performance of the machine’s internal components are crucial for long-term operational consistency. The heating element, pump, and control circuitry must operate reliably over extended periods to ensure uniform brewing parameters. Periodic maintenance and inspection are essential to identify and address any component degradation that could affect brewing consistency. Regular descaling is also important.

These facets collectively underscore the significance of operational consistency in the Avantco coffee maker. Their impact ensures a predictable, high-quality coffee product, crucial for managing customer expectations and maintaining operational efficiency in commercial establishments. Failure to address any of these facets can compromise the machine’s performance and undermine its intended purpose.

4. Durable component construction

Durable component construction is a defining characteristic of the Avantco coffee maker, directly influencing its longevity, reliability, and suitability for demanding commercial environments. The selection of robust materials and the implementation of sound engineering principles are essential to withstand the rigors of continuous operation and minimize downtime.

- Heating Element Integrity

The heating element, responsible for rapidly and consistently heating water, is subjected to thermal stress with each brewing cycle. Avantco coffee makers utilize heating elements constructed from high-grade stainless steel or Incoloy alloys, known for their resistance to corrosion, scaling, and thermal fatigue. Robust heating elements ensure consistent temperature maintenance, preventing fluctuations that compromise coffee quality. The heating element also dictates the energy efficiency of the coffee maker.

- Pump Mechanism Reliability

The pump mechanism, responsible for delivering water to the brewing chamber, requires durable construction to maintain consistent pressure and flow rate. Avantco designs incorporate positive displacement pumps made from brass or stainless steel, materials known for their resistance to wear and tear. A reliable pump ensures uniform water distribution across the coffee grounds, contributing to even extraction and consistent flavor. Pump failure leads to inconsistent brewing, and sometimes to equipment inoperability.

- Control Panel and Circuitry Protection

The control panel and associated circuitry regulate the brewing process and require protection from environmental factors such as moisture and temperature fluctuations. Avantco coffee makers employ sealed control panels with durable switches and controls, safeguarding internal components from damage. Over-current protection and surge suppression further protect the circuitry from electrical surges, enhancing the units overall reliability and lifespan. Electronic or physical damage here inhibits the operation of the coffee maker.

- Frame and Housing Material Strength

The frame and housing provide structural support and protect internal components from physical damage. Avantco coffee makers utilize stainless steel or heavy-duty polymer frames, offering resistance to corrosion, impact, and chemical exposure. A robust frame ensures stability and prevents damage to internal components during transport and operation. Damaged frames are also possible safety risks.

The durable component construction of the Avantco coffee maker translates directly to reduced maintenance costs, minimized downtime, and prolonged operational lifespan. These characteristics are essential for commercial establishments seeking reliable and cost-effective coffee brewing solutions.

5. Simplified user interface

The implementation of a simplified user interface in the Avantco coffee maker directly impacts its operational efficiency and reduces training overhead. The interface typically consists of intuitive buttons or controls, clearly labeled with brewing options, power settings, and timer functions. The presence of easily understandable indicators, such as lights or digital displays, allows operators to quickly ascertain the machine’s status and make necessary adjustments. A streamlined interface minimizes the likelihood of user error, ensuring consistent brewing parameters and predictable coffee quality. In a fast-paced commercial kitchen, every second counts, and a complex interface can lead to wasted time and inconsistent results. Example: Clear button indicators prevent the wrong cup of coffee from being brewed during a breakfast rush, reducing waste.

Furthermore, a simplified user interface reduces the reliance on specialized training for staff. New employees can quickly learn the basic operation of the Avantco coffee maker, enabling them to contribute to the workflow with minimal supervision. This ease of use also translates to reduced maintenance costs, as operators are less likely to mishandle the equipment due to confusion or lack of understanding. Example: Pictorial representation of brewing strength levels allows any employee to quickly serve regular or bold coffee with minimal training. By reducing time spent on equipment training, personnel can focus on customer service and other important tasks, improving overall productivity. A straightforward interface decreases operational costs by minimizing training time, reducing error rates, and limiting equipment damage.

In conclusion, the simplified user interface of the Avantco coffee maker is not merely a cosmetic feature; it is a critical component that enhances operational efficiency, reduces training requirements, and minimizes the risk of user error. These factors collectively contribute to improved productivity and reduced costs, making the machine a more attractive option for commercial establishments. While technological advancements may offer more complex interfaces, the Avantco prioritizes practicality and ease of use, ensuring consistent and reliable coffee brewing with minimal operational overhead.

Frequently Asked Questions

The subsequent questions and answers address common inquiries regarding the operation, maintenance, and selection of Avantco coffee makers. This information is intended to provide clarity and facilitate informed decision-making.

Question 1: What water quality standards are recommended for optimal performance?

Water hardness should be within the range of 50-100 ppm. Excessive mineral content leads to scale buildup, reducing heating efficiency and compromising coffee flavor. Regular water testing and filtration are advised.

Question 2: How often should the equipment be descaled?

Descaling frequency depends on water hardness and usage volume. A monthly descaling cycle is recommended for most commercial settings. More frequent descaling may be necessary in areas with particularly hard water.

Question 3: What type of filter is compatible with this equipment?

Avantco coffee makers typically utilize standard basket filters. Filter size and compatibility specifications are outlined in the equipment’s user manual.

Question 4: What is the appropriate coffee-to-water ratio for optimal brewing?

A coffee-to-water ratio of 1:16 (e.g., 1 gram of coffee per 16 grams of water) is generally recommended. Adjustments may be necessary based on desired coffee strength and bean characteristics.

Question 5: What preventative maintenance procedures are necessary for extending equipment lifespan?

Preventative maintenance includes regular cleaning, descaling, inspection of hoses and seals, and verification of calibration settings. Adherence to a scheduled maintenance program is crucial for ensuring long-term reliability.

Question 6: What steps should be taken if the unit fails to heat?

First, confirm that the unit is properly plugged in and that the power outlet is functioning. Second, check the heating element for signs of damage or burnout. If the heating element is intact, consult a qualified technician for further diagnosis and repair.

These answers provide a foundational understanding of Avantco coffee maker operation and maintenance. Consult the user manual for specific model details and troubleshooting guidance.

The following section will address potential challenges in operating a commercial coffee machine.

Conclusion

This discussion has explored facets of the Avantco coffee maker, emphasizing its design for commercial-grade brewing, volume capacity, operational consistency, durable construction, and simplified user interface. These elements collectively define its value proposition for establishments requiring reliable and efficient coffee production. Proper maintenance, informed operation, and adherence to recommended water quality standards are essential for maximizing the equipment’s lifespan and ensuring consistent beverage quality. The decision to integrate such equipment necessitates a thorough assessment of specific operational needs and a commitment to ongoing maintenance protocols.

The continued success of any establishment utilizing the Avantco coffee maker hinges on understanding its capabilities and limitations. The future outlook involves ongoing adherence to best practices in maintenance and a proactive approach to addressing potential operational challenges. A sustained focus on these areas will yield long-term benefits in beverage quality, operational efficiency, and overall customer satisfaction.

![Best Programmable 12 Cup Coffee Maker [Guide] The Ultimate Coffee Guide: Types, Brewing Methods & Best Beans Best Programmable 12 Cup Coffee Maker [Guide] | The Ultimate Coffee Guide: Types, Brewing Methods & Best Beans](https://deacoffee.com/wp-content/uploads/2026/02/th-300x200.jpg)