These coffee seeds undergo a brief roasting process, resulting in a lighter color and a higher density compared to their darker counterparts. This shorter roasting time preserves many of the bean’s original characteristics, leading to a more acidic and nuanced flavor profile. For instance, a bean from Ethiopia, when processed lightly, will often exhibit bright citrus and floral notes.

A shorter roasting period emphasizes the origin of the coffee, yielding unique and complex flavor profiles that distinguish it from more intensely processed options. The preservation of inherent compounds contributes to a higher concentration of chlorogenic acids, linked to various health benefits. Historically, lightly roasted coffee was favored for its perceived stimulating effects and cleaner taste, particularly in regions where coffee cultivation originated.

Further discussion will focus on the specific flavor attributes resulting from this treatment, optimal brewing techniques for extracting its full potential, and the growing trend of coffee enthusiasts seeking out these distinctive and flavorful options in the contemporary coffee landscape.

Tips for Optimal Light Roast Coffee Bean Preparation

Achieving the full potential of these beans requires careful consideration of several factors. Adherence to these guidelines will enhance the overall coffee experience.

Tip 1: Grind Freshly Before Brewing: Grinding immediately prior to brewing preserves volatile aromatic compounds, ensuring maximum flavor extraction. Pre-ground coffee loses its intensity quickly.

Tip 2: Utilize Water at the Correct Temperature: Water heated to between 195-205F (90-96C) is ideal. Temperatures outside this range can lead to under-extraction (sourness) or over-extraction (bitterness).

Tip 3: Employ a Brewing Method That Highlights Nuance: Pour-over methods, such as Hario V60 or Chemex, allow for precise control over the brewing process, revealing the subtle flavor characteristics often present. Immersion brewing also can be a suitable method.

Tip 4: Experiment with Grind Size: Fine-tuning the grind size based on the brewing method is crucial. A coarser grind is generally preferable for pour-over, while a finer grind may be better suited for espresso.

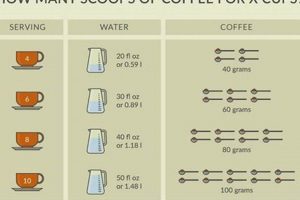

Tip 5: Adjust the Coffee-to-Water Ratio: A common starting point is a 1:15 ratio (e.g., 1 gram of coffee to 15 grams of water). Adjust this ratio based on personal preference and the specific characteristics of the chosen beans.

Tip 6: Consider Water Quality: The quality of water significantly impacts the final cup. Filtered water, free of chlorine and other impurities, is recommended.

Tip 7: Pre-wet the Grounds: Bloom the coffee grounds with a small amount of hot water (approximately twice the weight of the coffee) for 30 seconds before beginning the main brewing process. This allows gases to escape and improves extraction.

By implementing these techniques, one can unlock the inherent complexity and brightness these beans offer, leading to a more satisfying and flavorful cup.

The subsequent sections will elaborate on specific flavor profiles and offer additional brewing considerations.

1. Acidity and Brightness

The defining feature of coffee roasted to a lighter degree is its pronounced acidity and brightness. This characteristic arises from the shorter roasting time, which preserves organic acids inherently present in the green coffee bean. These acids, such as citric, malic, and phosphoric acids, contribute to a vibrant and often tangy sensation on the palate. The term “brightness” refers to this lively, clean, and refreshing quality. For instance, an East African coffee, lightly roasted, typically exhibits a distinct citrus-like acidity, while a Central American counterpart might present a malic acid-driven profile reminiscent of green apples. Understanding this relationship is critical because it directly influences the perceived flavor intensity and complexity of the final beverage. Without sufficient acidity, the coffee can taste flat and uninteresting.

The level of acidity is not only determined by roasting, but also by origin, processing method, and bean variety. Washed processed coffees, for example, often exhibit higher acidity than naturally processed coffees due to the removal of the fruit pulp before drying. Additionally, higher grown coffees tend to have more complex acidity due to slower maturation. Brewing method also plays a significant role in extracting acids. Pour-over and drip methods generally accentuate acidity, whereas immersion methods, like French press, may yield a smoother, less acidic cup. Careful extraction is key to balancing acidity with sweetness and body, preventing an overly sour or astringent taste.

In summary, the interplay between acidity and brightness is paramount in defining the qualities. The shorter roasting time preserves organic acids, enhancing brightness and providing a tangible sensory experience. This connection informs both the selection of beans and the adoption of specific brewing techniques to optimally balance these elements, addressing the challenge of maximizing flavor clarity without compromising the overall balance of the cup.

2. Origin Characteristics

The inherent qualities dictated by a coffee bean’s origin are critically highlighted when subjected to a lighter roasting profile. This minimal processing allows the unique terroir and processing methods to exert a dominant influence on the final cup, presenting a clearer expression of the bean’s natural characteristics.

- Terroir and Flavor Expression

Terroir, encompassing the climate, soil, and altitude of the growing region, significantly shapes the bean’s chemical composition and subsequently its flavor. For example, a high-altitude Kenyan coffee may exhibit a vibrant black currant acidity and complex floral aromas, while a Sumatran coffee, influenced by its volcanic soil and humid climate, might display earthy undertones and a heavier body. The reduced roasting time characteristic preserves these nuanced differences, ensuring that the origin’s signature characteristics are not masked by the roasting process.

- Processing Method Influence

The method used to process coffee cherries after harvesting significantly impacts the resulting flavor profile. Washed coffees, characterized by their clean and bright flavors, benefit from light roasting as it accentuates their inherent clarity and acidity. Conversely, naturally processed coffees, dried with the fruit intact, often possess a heavier body and fruity sweetness; light roasting allows these attributes to shine without introducing excessive roast character. The choice of processing method, therefore, becomes integral to the final cup’s expression.

- Varietal Specificity

Different coffee varietals, such as Gesha, Typica, or Bourbon, possess distinct flavor profiles. These nuanced differences are best appreciated when the beans are lightly roasted. Gesha beans, known for their delicate floral and tea-like qualities, require a subtle roast to preserve their inherent complexity. Lighter roasting highlights the varietals unique attributes, enabling a more discernible and authentic sensory experience.

- Altitude and Density Correlation

Coffee grown at higher altitudes typically exhibits greater density, resulting in a more complex flavor profile and heightened acidity. Light roasting preserves these desirable qualities, preventing the degradation of delicate aromatics and volatile compounds. The denser bean structure also withstands the roasting process better, allowing for a more even and consistent development of flavor.

In essence, the deliberate underdevelopment of the roasting process emphasizes the inherent characteristics of the bean’s origin. It requires a deep understanding of the coffees terroir, processing method, varietal, and growing conditions. The roaster becomes more of a curator, showcasing the bean’s natural qualities rather than imposing a uniform roast flavor, revealing the diversity and complexity inherent in the world of specialty coffee.

3. Bean Density

Bean density, a physical property of coffee beans, profoundly impacts the outcome of lighter roasting profiles. This characteristic influences heat transfer during roasting, flavor development, and ultimately, the overall quality of the brewed coffee. Understanding the interplay between bean density and the roasting process is therefore crucial for achieving desired flavor characteristics.

- Heat Absorption and Conduction

Denser beans require more energy to reach the same internal temperature as less dense beans. During roasting, this translates to a slower and more even heat absorption. This controlled heat penetration can mitigate scorching on the bean’s surface, allowing for a more uniform development of flavor compounds throughout the bean’s structure. The internal moisture of denser beans, which is higher, also creates a more even roast as the moisture creates steam and acts as a moderator. For example, high-altitude grown Arabica beans, known for their density, often exhibit a more balanced and nuanced flavor when lightly roasted.

- Flavor Compound Development

Density affects the transformation of complex carbohydrates and acids within the bean. Denser beans, with their more complex cellular structure, tend to produce a wider range of flavor precursors during the initial stages of roasting. When lightly roasted, these precursors are preserved and contribute to a brighter acidity, complex sweetness, and layered aromatics. Conversely, less dense beans might lack the necessary structure to support this intricate development, resulting in a flatter, less interesting cup.

- Roast Evenness and Consistency

Light roasting amplifies any inconsistencies in bean density within a batch. If a batch contains a mix of dense and less dense beans, the less dense beans will develop faster and may exhibit undesirable grassy or sour notes, while the denser beans remain under-developed. This unevenness degrades the overall flavor profile. Careful sorting and grading of green beans based on density is therefore essential to ensure a consistent and predictable roasting outcome. Utilizing a density separator after sorting is critical.

- Extraction Efficiency

The cellular structure of dense beans resists water penetration during brewing. Achieving optimal extraction from lightly roasted, dense beans requires a finer grind size and potentially higher water temperatures. Under-extraction can result in a sour and thin-bodied cup, while over-extraction can lead to bitterness. Precise control over brewing parameters is therefore crucial to unlock the full potential of dense beans. Dialing in recipes for the coffees by testing and taste is key.

The interplay between bean density and roasting provides a crucial lens for evaluating the potential and challenges associated with this style. Careful consideration of bean density is crucial for optimizing the light roasting process and enhancing the complexity and nuances of the final cup.

4. Caffeine Retention

A notable attribute associated with minimally processed coffee seeds is their relatively high caffeine content compared to darker roasts. The application of less heat during roasting results in less degradation of caffeine molecules, thus maintaining a higher concentration within the finished product. This difference stems directly from the chemical changes induced by extended roasting times, where prolonged exposure to heat causes a reduction in caffeine levels. The direct result of shorter roasting times is more caffeine.

The extent of caffeine retention in the is not merely a matter of academic interest. Consumers often seek specific caffeine levels for particular effects, ranging from alertness to performance enhancement. Furthermore, an understanding of this caffeine retention provides valuable insights for coffee producers and roasters aiming to cater to diverse consumer preferences. For instance, certain coffee shops promote their lightly roasted options as providing a stronger caffeine kick, thus attracting customers looking for an energy boost. The caffeine amounts will vary from bean to bean, but overall the trend of caffeine retention has been proven.

In summary, light roast coffee bean retains a greater proportion of its original caffeine content due to the shorter roasting process. This characteristic is not only a significant selling point for consumers seeking a higher-caffeine beverage but also a crucial consideration for producers and roasters aiming to optimize their product offerings. While roasting will influence the amount, the main variable for how much caffeine a bean has is still going to be dependent on the type of bean used.

5. Roasting Time

The duration of the roasting process is the defining characteristic of coffee seeds prepared in this manner. This temporal element directly influences the bean’s chemical composition, flavor profile, and overall suitability for various brewing methods. The following factors elaborate on the crucial aspects of roasting time.

- Development of Volatile Compounds

Shorter roasting times, typically ranging from 8 to 12 minutes, preserve a greater proportion of volatile aromatic compounds within the bean. These compounds, which contribute to the coffee’s nuanced flavors and aromas, are susceptible to degradation under prolonged heat exposure. For instance, a bean roasted for 10 minutes will retain more of its floral or fruity notes compared to a bean roasted for 15 minutes. These volatile compounds give the coffee brightness and complexity.

- Caramelization and Maillard Reaction

While these reactions occur during the roasting process, the degree to which they develop is limited in the case. The Maillard reaction, responsible for browning and the development of complex flavors, requires time and heat. With shorter roasting durations, these reactions are truncated, resulting in less body and less developed sweetness compared to darker roasts. As a result, light roasting can be hard, and it takes skill to get right.

- Moisture Content Reduction

The roasting process reduces the moisture content within the green coffee bean. Lighter roasting profiles necessitate careful monitoring of moisture levels to avoid underdevelopment. If roasting stops too soon, the bean can retain excessive moisture, leading to a grassy or sour taste. Achieving the optimal balance between moisture reduction and flavor development is critical for this coffee.

- Acidity Level Control

Roasting time directly impacts the perceived acidity in the final cup. Shorter roasting times preserve the inherent organic acids within the bean, resulting in a brighter and more acidic profile. This acidity, while desirable for some, requires careful management to prevent an overly sour or unbalanced cup. Proper preheating of the roaster and sufficient airflow can help moderate acidity.

In summary, the duration significantly determines the characteristics of coffee prepared in this style. By carefully controlling the roasting time, roasters can manipulate the development of volatile compounds, manage acidity levels, and ensure adequate moisture reduction, ultimately influencing the coffee’s flavor profile and overall quality. Short times are very popular now, but a great deal of precision is required to produce the correct outcome.

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding the characteristics, preparation, and suitability of coffee prepared with a lighter roast profile.

Question 1: Does light roast coffee have more caffeine?

Generally, yes. Shorter roasting times preserve more caffeine compared to darker roasts. However, the varietal and origin of the bean are more influential factors.

Question 2: Is light roast coffee more acidic?

Yes, typically. Shorter roasting times preserve the natural organic acids present in the green bean, resulting in a brighter and more acidic cup.

Question 3: Is it more difficult to brew properly?

Lightly roasted coffee requires greater precision in brewing. Factors such as grind size, water temperature, and brewing time must be carefully controlled to achieve optimal extraction.

Question 4: Does it taste sour or underdeveloped?

If brewed improperly, lightly roasted coffee can indeed taste sour or underdeveloped. These flavors indicate under-extraction, often due to too coarse of a grind or insufficient brewing time.

Question 5: Is it suitable for espresso?

While possible, light roast coffees can be challenging for espresso due to their density and higher acidity. Precise grinding and tamping are essential to achieve a balanced shot.

Question 6: How does the origin impact the taste?

The shorter roasting process allows the origin characteristics to shine through. Terroir, processing methods, and varietal differences become more pronounced in lightly roasted coffee.

In essence, this style offers a complex and nuanced flavor experience. Proper preparation and an appreciation for origin characteristics are essential to fully appreciate its potential.

The subsequent section will explore advanced brewing techniques and flavor pairing suggestions for enthusiasts.

Conclusion

The preceding exploration has illuminated the multifaceted nature of coffee, emphasizing the critical role that roasting plays in shaping its final characteristics. From its inherent bean density and caffeine retention to the profound impact of roasting time and origin characteristics, a meticulous understanding of these factors is paramount for both producers and consumers. These variables shape flavor and brew methods.

Ultimately, the appreciation of the bean requires a discerning palate and a commitment to precise brewing techniques. As the specialty coffee industry continues to evolve, further research and experimentation are essential to unlock the full potential and ensure a consistently exceptional coffee experience. Continuing to investigate the brewing process will allow for greater control over the final product.