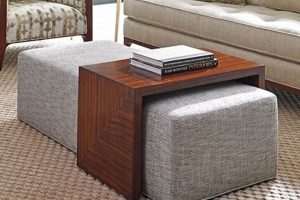

This furniture piece combines functionality and aesthetics, typically featuring a neutral color and a rising tabletop. This dual-purpose design is often found in living rooms or dens, serving as both a surface for display and a convenient workspace or dining area. An example is a low, rectangular furnishing with a painted surface in a muted shade, where the upper panel can be elevated to a more comfortable height.

Its value lies in maximizing space and providing versatility. The elevating mechanism allows users to transition from a casual setting to a more practical one for eating or working. Historically, such convertible furniture gained popularity in smaller living spaces, offering a solution to the challenges of limited room. The color choice adds a sense of sophistication and easily integrates into various interior design schemes.

The following sections will delve into specific aspects, including design variations, material considerations, and practical applications within different home environments. Further discussion will address factors to consider when selecting this type of furniture and maintenance tips to ensure its longevity.

Tips for Selecting and Maintaining a Lift-Top Coffee Table

This section provides essential guidance for choosing and caring for furniture of this design, ensuring longevity and optimal functionality.

Tip 1: Assess Spatial Requirements. Prior to purchase, measure the available space. Consider the unit’s dimensions in both its standard and elevated configurations to ensure comfortable movement within the room.

Tip 2: Evaluate Material Durability. Examine the construction materials carefully. Solid wood or high-quality engineered wood offers superior stability and resistance to wear. The lifting mechanism should also be constructed of robust metal components.

Tip 3: Inspect Lifting Mechanism Quality. Test the elevation system thoroughly. It should operate smoothly, quietly, and securely lock into place at various heights. Avoid models with flimsy or unstable mechanisms.

Tip 4: Consider Storage Capacity. Many models offer integrated storage beneath the lifting top. Evaluate the size and accessibility of this storage area to ensure it meets specific organizational needs.

Tip 5: Prioritize Surface Finish. The finish should be resistant to scratches, stains, and moisture. Opt for finishes that are easy to clean and maintain. Consider the color and texture to complement existing dcor.

Tip 6: Regular Cleaning Practices. Employ non-abrasive cleaning agents to prevent surface damage. Dust regularly and address spills promptly to avoid staining or warping.

Tip 7: Periodic Mechanism Inspection. Routinely inspect the lifting mechanism for any signs of wear or looseness. Tighten screws or lubricate moving parts as needed to maintain smooth operation.

By adhering to these guidelines, consumers can make informed decisions, ensuring lasting satisfaction and utility from this versatile furniture piece.

The following sections will expand on the practical applications and design considerations to enhance interior spaces.

1. Versatile Surface

The versatile surface is an inherent element of the design and contributes significantly to its overall utility. The rising tabletop transforms a standard furnishing into a multi-functional zone. This is critical in compact living environments, as it mitigates the need for separate dining or work surfaces. For example, an individual living in a studio apartment can readily convert a seating area into a dining space, thus eliminating the requirement for a dedicated dining table. The “Versatile Surface” functionality is not merely an added feature but an integral design aspect directly impacting the user experience.

The practical impact of a “Versatile Surface” extends to adaptability in various activities. It functions as a standard surface for displaying decorative items when lowered and serves as an ergonomic workspace when elevated. Consider a professional who works from home; this design offers a distinct advantage by facilitating posture correction and comfort during prolonged work sessions. This functionality alleviates stress on the back and neck, and increases productivity during the working hours.

In summary, the “Versatile Surface” defines the transformative quality of this type of furniture. It enhances its value by enabling seamless transitions between different applications, addressing space constraints, and promoting user comfort. The inherent flexibility solves practical living challenges, making the design a functional addition to modern interiors. The success of this furniture hinges on this specific attribute.

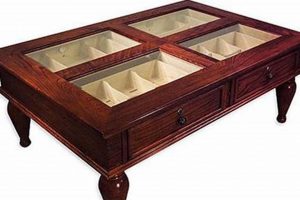

2. Storage Solution

The “Storage Solution” aspect is intrinsically linked to the functional design of a product, augmenting its appeal, particularly in space-constrained environments. The lifting mechanism is often designed to reveal a concealed compartment beneath the tabletop. This under-surface storage space provides a convenient location to store various items such as remote controls, magazines, blankets, and laptops, thereby minimizing clutter in the surrounding area. A direct consequence of incorporating this storage functionality is the improved organization and enhanced aesthetic appeal of the living space. The importance of this lies in its ability to offer a practical solution for maintaining a tidy and visually pleasing interior without sacrificing valuable floor space. For instance, in an apartment where square footage is limited, this furnishing offers both a surface for daily activities and a discrete location for storing personal items, reducing the need for additional storage units.

Furthermore, the integration of a “Storage Solution” significantly impacts the user’s lifestyle. By providing easy access to frequently used items, such as reading materials or electronic devices, this design feature enhances convenience and overall user satisfaction. A real-world example illustrates this benefit: a family with young children can utilize the storage compartment to stow away toys and games after playtime, effectively managing clutter and creating a more organized environment. In terms of practical applications, a college student residing in a small dorm can leverage the available storage to hold textbooks and school supplies, optimizing the limited space and ensuring efficient access to study materials. It should be mentioned the benefits of cleaning is enhanced and items can be protected from sunligt and dust.

In summary, the “Storage Solution” is more than just an added feature; it is a critical design element that significantly contributes to the overall functionality and practicality. The furniture addresses the pervasive issue of clutter management in modern living spaces. Its integration transforms the function from a mere surface into a multi-purpose furniture piece, making it indispensable. Incorporating storage resolves functional problems to enhance lifestyle and contributes positively to the efficient organization of a living area. Further design innovations should focus on optimizing the storage space and ensuring the compartment is easily accessible and user-friendly, to maximize the benefits to the end-users.

3. Neutral Aesthetic

The inherent design characteristic of “Neutral Aesthetic” profoundly influences the appeal and versatility of the “gray coffee table lift top.” The selection of a neutral color palette, specifically gray, functions as a deliberate strategy to maximize compatibility with diverse interior design schemes. This adaptability is crucial, as it allows the furniture piece to seamlessly integrate into various living spaces, irrespective of existing color schemes or decorative styles. The causal relationship is evident: the gray color choice directly contributes to the furniture’s enhanced marketability and wider consumer appeal. Furthermore, it provides a subtle yet effective way to introduce a sense of sophistication without overpowering the existing aesthetic. This understated elegance translates into practical benefits, as it reduces the risk of aesthetic clashes and ensures that the furniture remains visually relevant over time.

The importance of “Neutral Aesthetic” as a component of a lift-top version lies in its capacity to complement both the functional and stylistic aspects of the furniture. The subdued gray provides a visual anchor that balances the inherent complexity of the lift mechanism. This functionality requires a balance between engineering and design. The color itself helps to minimize the furniture’s visual footprint. It creates a subdued aesthetic effect. For example, in a minimalist apartment, a bright color might clash with the theme. The gray finish will likely blend seamlessly. Additionally, the application of neutral hues is often coupled with minimalist design principles, resulting in a streamlined furniture piece that optimizes space and minimizes visual clutter. A real-world example would be a contemporary living room where the “gray coffee table lift top” subtly enhances the overall aesthetic. It complements the existing neutral shades without drawing unnecessary attention, while providing a functional surface.

In summary, the “Neutral Aesthetic” is not merely a stylistic choice but an integral design element that significantly enhances the overall value. It ensures adaptability and relevance within varying interior designs. It reinforces its value through both functional and aesthetic integration. The challenges associated with color trends and changing consumer preferences are mitigated by its timeless appeal. The benefits extend beyond visual appeal, contributing to practicality and the long-term relevance of the furniture. The color is integral for the success of this design.

4. Durable Build

The structural integrity, referred to as “Durable Build,” is paramount to the functionality and longevity of a “gray coffee table lift top.” The stresses inherent in the elevating mechanism and daily use necessitate a robust construction.

- Material Composition and Load-Bearing Capacity

The choice of materials directly impacts the “Durable Build.” Solid hardwoods, high-density composites, and reinforced metals are common. The material selection determines the furniture’s ability to withstand static loads, such as decorative objects, and dynamic loads associated with the lifting and lowering of the tabletop. A “gray coffee table lift top” constructed from lower-quality materials is susceptible to warping, cracking, or mechanical failure, reducing its lifespan. A “gray coffee table lift top” made from solid wood, reinforced with a steel frame underneath the lift top can bear loads up to 75lbs without structural issues.

- Joint Construction and Fastening Techniques

The method by which individual components are joined significantly contributes to the overall stability. Dovetail joints, mortise-and-tenon joints, and reinforced screw fixings enhance structural rigidity. Inferior joint construction, such as simple butt joints secured with weak adhesives, compromises the furniture’s ability to withstand stress. A “gray coffee table lift top” with inadequately reinforced joints is prone to wobbling or complete joint failure, rendering it unusable. Quality construction often employes high-grade fasteners and adhesives to prevent loosening over time.

- Finish Durability and Resistance to Wear

The surface finish not only enhances the aesthetic appeal but also protects the underlying material from damage. A durable finish resists scratches, stains, and moisture penetration. A poorly applied finish, or a finish made from low-quality components, is prone to chipping, peeling, or discoloration, diminishing the furniture’s appearance and potentially compromising its structural integrity. A “gray coffee table lift top” with a catalyzed lacquer finish will resist household chemicals and moisture better than one with a simple varnish. Regularly polishing the finished surface prevents damages and protects the “gray coffee table lift top”.

- Mechanism Stability and Lifespan

The lifting mechanism itself must be constructed from durable materials and designed to withstand repeated use. High-gauge steel and precision engineering are essential for smooth operation and long-term reliability. A poorly designed or constructed mechanism can bind, jam, or fail prematurely, requiring costly repairs or replacement. A “gray coffee table lift top” that utilizes a gas-spring mechanism will provide a smoother, controlled lift compared to a simple hinge system and will likely have a longer functional life. Regular maintenace may be required to avoid having the mechanism start squeaking.

These facets of “Durable Build” collectively determine the long-term usability and value of a “gray coffee table lift top.” Compromises in any of these areas will reduce the furniture’s lifespan, increase the likelihood of functional problems, and diminish its overall appeal. Quality materials and construction are crucial for a furniture piece that sees regular use and is expected to last for many years. For example, cheaper lift-top mechanism may only last 2 -3 years while a quality mechanism will last 10+ years.

5. Smooth Lift

The operational attribute of a “Smooth Lift” is fundamental to the user experience and overall utility. The absence of a smooth elevation translates directly into user dissatisfaction and diminished functionality. The lifting mechanism must operate with minimal friction, noise, and instability. A mechanism characterized by jerky movements, audible squeaks, or significant resistance detracts from the product’s perceived value and functional convenience.

The importance of “Smooth Lift” as a core component of a “gray coffee table lift top” stems from its direct impact on ease of use and safety. A smooth, controlled ascent and descent prevent accidental spills or damage to items placed on the tabletop. It also minimizes the risk of injury, particularly for users with limited strength or mobility. For example, a lift mechanism with excessive resistance may require significant force to operate, potentially leading to strain or injury. Conversely, a “Smooth Lift” ensures effortless operation, making the furniture accessible to a broader range of users.

The practical significance of understanding the nuances of “Smooth Lift” lies in enabling informed purchasing decisions. Consumers should evaluate the lifting mechanism’s smoothness, stability, and noise level before making a purchase. Mechanisms employing gas springs or high-quality hinges tend to offer a superior “Smooth Lift” compared to simpler, less sophisticated designs. The challenge lies in balancing the need for a smooth, reliable lift with cost considerations. Consumers must weigh the benefits of a higher-quality mechanism against their budget constraints. The value of a “gray coffee table lift top” is significantly enhanced by a “Smooth Lift”, contributing to long-term user satisfaction.

Frequently Asked Questions About Gray Coffee Table Lift Tops

This section addresses common inquiries regarding the features, selection, and maintenance of gray coffee table lift tops.

Question 1: What are the primary benefits of a gray coffee table lift top?

A gray coffee table lift top provides a versatile surface for dining or working, integrated storage, and a neutral aesthetic that complements various dcor styles. These tables are particularly beneficial for small living spaces, offering enhanced functionality without occupying additional square footage.

Question 2: What material considerations are important when selecting this type of furniture?

Durable materials, such as solid wood or high-quality engineered wood, are essential for the base and tabletop. The lifting mechanism should be constructed from robust metal components to ensure smooth operation and longevity. The surface finish should be resistant to scratches, stains, and moisture.

Question 3: How does the lifting mechanism contribute to the furniture’s overall value?

A smooth, stable, and quiet lifting mechanism is crucial for user satisfaction and safety. Gas-spring mechanisms or high-quality hinges are preferred for their controlled ascent and descent, minimizing the risk of spills or injury.

Question 4: What maintenance practices are recommended to prolong the life of a gray coffee table lift top?

Regular dusting, prompt spill cleanup, and periodic inspection of the lifting mechanism are essential. Non-abrasive cleaning agents should be used to prevent surface damage. Screws should be tightened and moving parts lubricated as needed.

Question 5: How does the gray color enhance the furniture’s versatility?

The neutral gray tone allows this furniture to seamlessly integrate into various interior design schemes, irrespective of existing color palettes or decorative styles. This adaptability ensures that the furniture remains visually relevant over time.

Question 6: What should be considered regarding the storage capacity of these tables?

The size, configuration, and accessibility of the integrated storage area should be evaluated based on individual organizational needs. This feature offers a convenient location for storing items such as remote controls, magazines, or blankets.

The key takeaways from these FAQs highlight the importance of material quality, mechanism functionality, and aesthetic considerations when selecting and maintaining a gray coffee table lift top.

The following section will explore design trends and variations to broaden the understanding of this furniture piece.

Conclusion

The exploration of the gray coffee table lift top underscores its multifaceted value as a furniture piece. Key points include its space-saving versatility, inherent storage capabilities, adaptable aesthetic, structural resilience, and the significance of a smooth lifting mechanism. These factors collectively contribute to its functional appeal and potential to enhance modern living spaces.

As trends in interior design evolve, the gray coffee table lift top represents a pragmatic solution to spatial constraints and functional demands. Continued innovation in materials, mechanisms, and design integration will determine its ongoing relevance and utility in contemporary homes. Prospective buyers and designers should carefully consider these attributes to ensure informed selections that maximize value and long-term satisfaction.