Custom drinkware, specifically ceramic vessels designed for hot beverages, can undergo a permanent marking process using focused light beams. This technique alters the surface of the material, creating intricate designs, logos, or personalized text. The resulting product is durable, dishwasher-safe, and resistant to fading, offering a long-lasting customized solution.

This method provides a unique and professional way to personalize items for gifting, corporate branding, or individual expression. The permanency of the marking ensures that the design remains intact over time, providing lasting value. Historically, customization of drinkware relied on methods prone to wear and tear, while this modern approach provides superior quality and durability.

The following sections will delve into the intricacies of the process, explore the diverse applications, and examine the cost-effectiveness and considerations for those seeking this type of customized product.

Tips for Selecting Quality Laser Etched Coffee Mugs

The selection of customized drinkware requires careful consideration to ensure both aesthetic appeal and lasting value. The following guidelines provide insight into maximizing satisfaction with this product.

Tip 1: Material Selection: Consider the type of ceramic used. Higher-quality ceramics offer improved durability and a more refined aesthetic. Options range from standard stoneware to finer porcelain or bone china, each with varying levels of heat resistance and visual appeal.

Tip 2: Design Complexity: Intricate designs require a higher level of precision. Complex artwork may necessitate a higher cost and a more experienced operator. Evaluate the design’s suitability for the marking process.

Tip 3: Etch Depth and Clarity: The depth and clarity of the marking determine its longevity and visual impact. Inquire about the laser’s power and resolution to ensure a clean, well-defined result. Deeper markings tend to be more durable.

Tip 4: Customization Options: Explore the full range of customization options available. This may include the placement of the design, the size of the marked area, and the possibility of wrapping designs around the entire mug.

Tip 5: Proofing Process: Always request a digital proof before production begins. This allows for a review of the design’s placement, size, and overall appearance on the mug. Address any concerns or modifications at this stage.

Tip 6: Supplier Reputation: Choose a supplier with a proven track record of producing high-quality, custom-marked items. Look for reviews, testimonials, and examples of their work to assess their capabilities.

Tip 7: Cleaning and Care Instructions: Inquire about the proper cleaning and care procedures. Although the marking is permanent, certain harsh chemicals or abrasive cleaners may damage the surrounding ceramic surface.

Following these guidelines will contribute to a successful outcome, ensuring a personalized item that meets expectations for both quality and visual appeal. These careful considerations will maximize the value and longevity of the customized product.

The next section will address common applications and use cases for personalized ceramic beverage containers.

1. Material Durability

The material from which a ceramic beverage container is constructed directly impacts the longevity and overall value of a product featuring surface marking via focused light beam technology. The intrinsic strength and resistance to physical stress determine the vessel’s capacity to withstand routine use, temperature fluctuations, and potential impacts. Lower-grade ceramics, such as porous earthenware, are inherently more susceptible to chipping, cracking, and thermal shock, potentially compromising the integrity of the etched design and rendering the item unusable. Conversely, denser materials like porcelain or stoneware exhibit superior resilience, preserving both the structural integrity of the mug and the aesthetic quality of the surface marking over an extended period.

The etching process, while creating a permanent mark, does introduce localized stress to the material. If the base ceramic possesses inherent weaknesses, the etching process could exacerbate pre-existing flaws, leading to premature failure. For example, a mug made from poorly vitrified clay could develop micro-cracks around the etched area, eventually leading to structural failure with repeated heating and cooling. Proper material selection mitigates this risk, ensuring that the customization process does not compromise the structural integrity of the vessel. This underscores the necessity of considering the ceramic’s composition, firing temperature, and overall manufacturing quality when choosing substrates for laser-based customization.

In conclusion, material durability is a foundational element influencing the performance and lifespan of customized ceramic beverage containers. While the surface marking offers aesthetic enhancement and personalization, the underlying material’s strength dictates the product’s ability to withstand real-world use. Prioritizing high-quality, durable ceramics minimizes the risk of damage, thereby maximizing the value and longevity of the personalized item. This focus on material properties ultimately contributes to a more satisfying and sustainable consumer experience.

2. Design Precision

Design precision, in the context of laser etching on ceramic drinkware, signifies the accuracy and fidelity with which a design is transferred onto the mug’s surface. It is a critical factor determining the aesthetic appeal and perceived quality of the finished product, directly influencing its suitability for applications ranging from promotional items to personalized gifts.

- Raster Resolution and Dot Density

Raster resolution, measured in dots per inch (DPI), dictates the level of detail a laser can reproduce. Higher DPI values translate to finer lines and more intricate patterns. A low DPI setting results in pixelated or blurred images, particularly noticeable in curved or complex designs. For instance, reproducing a detailed company logo requires a high DPI to maintain legibility and brand integrity. Insufficient resolution degrades the visual impact and diminishes the perceived value of the product.

- Vector Accuracy and Path Following

Vector accuracy refers to the laser’s ability to precisely follow predefined paths. This is crucial for creating clean, sharp lines and defined edges, especially in geometric shapes or text. Deviations from the intended path result in jagged or uneven markings, compromising the design’s aesthetic appeal. Consider a design featuring a series of interlocking circles; inaccurate path following leads to distorted shapes and a poorly executed visual. Maintaining vector accuracy is paramount for achieving professional-grade results.

- Calibration and Alignment

Proper calibration and alignment of the laser system are essential for consistent and predictable results. Misalignment can lead to skewed images, inconsistent etching depths, and variations in marking quality across different mugs. For example, if the laser is not properly aligned with the mug’s rotational axis, a circular design may appear elliptical or distorted. Regular calibration procedures are necessary to ensure the accuracy and repeatability of the etching process. Failure to maintain proper alignment results in inconsistencies and rejects, increasing production costs and diminishing customer satisfaction.

- Material Consistency and Laser Parameters

Ceramic composition and surface texture influence the laser’s interaction with the material. Variations in ceramic density, glaze thickness, or surface irregularities can affect the etching depth and contrast. Precise control over laser power, speed, and pulse frequency is necessary to compensate for these material variations and achieve consistent results. Inconsistent laser parameters can lead to uneven markings, burned edges, or insufficient contrast. Optimizing laser settings for each specific ceramic type is crucial for achieving uniform and high-quality etching.

These facets of design precision collectively determine the quality and visual appeal of laser etched coffee mugs. Maintaining high standards in raster resolution, vector accuracy, system calibration, and laser parameter optimization ensures that designs are reproduced accurately, consistently, and with exceptional detail, enhancing the perceived value and utility of the customized drinkware. The pursuit of design precision directly translates to a superior product that effectively conveys the intended message or aesthetic.

3. Etching Permanence

Etching permanence, concerning laser-marked ceramic drinkware, refers to the ability of the etched design to resist degradation and maintain its visual integrity over an extended period of use. This characteristic is paramount in determining the long-term value and utility of such items, particularly in applications where branding or personalization is crucial.

- Material Ablation and Depth Control

The laser etching process involves material ablation, where focused energy removes a thin layer of the ceramic surface to create the design. The depth of this ablation directly correlates with the design’s resistance to wear. Shallow etchings are susceptible to fading or disappearing with repeated washing or abrasion, while deeper, controlled ablations create a more permanent mark. Precise control of laser power and pulse duration is necessary to achieve optimal depth without compromising the structural integrity of the ceramic. For example, a promotional mug designed for daily use should feature an etching depth sufficient to withstand hundreds of dishwasher cycles without noticeable degradation.

- Resistance to Chemical Degradation

Household detergents, cleaning agents, and even certain food substances can contribute to the degradation of etched surfaces over time. The etched area, being a modified surface, may exhibit different chemical properties compared to the surrounding glaze. Therefore, the etching process must be optimized to create a chemically stable mark that resists discoloration, staining, or dissolution upon exposure to common household chemicals. For instance, an etched coffee mug repeatedly washed with an abrasive cleaner may experience accelerated fading if the etching is not chemically resistant.

- Thermal Stability and Crack Propagation

Ceramic drinkware is frequently subjected to thermal stress from hot beverages and temperature changes during washing. The laser etching process can introduce micro-cracks or thermal stress points in the ceramic, potentially leading to crack propagation and design degradation. The etching parameters must be carefully controlled to minimize thermal impact and ensure that the etched area remains stable under varying temperature conditions. For example, rapidly cooling a hot, etched mug may induce thermal shock, causing the etching to fracture or delaminate if not properly executed.

- UV Resistance and Color Stability

Prolonged exposure to ultraviolet (UV) radiation can cause fading or discoloration of certain etched designs, particularly those incorporating colored glazes or surface treatments. The etching process may alter the UV resistance of the ceramic surface, making it more susceptible to fading over time. Selecting UV-resistant materials and optimizing the etching parameters to minimize surface alteration can enhance the long-term color stability of the design. A mug left on a sunny windowsill will experience accelerated fading of the etching if the mark isn’t properly UV stable.

These interconnected facets underscore the complexities involved in achieving etching permanence on ceramic beverage containers. A comprehensive understanding of material properties, laser parameters, and environmental factors is crucial for producing durable, long-lasting etched designs that withstand the rigors of daily use. Properly executed, laser marking offers a superior alternative to traditional printing methods, ensuring lasting personalization and brand visibility. By contrast, techniques such as pad printing tend to exhibit significant fading, peeling, or complete removal over time.

4. Customization Breadth

Customization breadth, when applied to laser-etched coffee mugs, dictates the range of design possibilities and functional enhancements available to the end user. This encompasses factors such as the area available for etching, the complexity of designs that can be accurately reproduced, the choice of fonts and graphics, and the option to include personalized text or logos. A wider customization breadth directly translates to a more versatile product, capable of satisfying diverse customer needs and accommodating varied branding requirements. For instance, a limited customization breadth might restrict a user to simple text or basic geometric shapes, whereas an expansive customization breadth allows for intricate logos, detailed artwork, and personalized messaging, thereby increasing the mug’s appeal and perceived value.

The practical significance of understanding customization breadth lies in its ability to drive purchasing decisions and enhance brand recognition. Businesses seeking promotional items, for example, benefit from a wider range of design options to effectively convey their brand identity. A coffee shop chain might utilize laser etching to incorporate its logo, a specific design motif, and a customer’s name onto a mug, creating a personalized and memorable item. Conversely, an organization with strict brand guidelines may require precise control over design elements, necessitating a laser etching process that can accurately reproduce their logo with consistent font styles and color fills. The greater the customization breadth, the more effectively the coffee mug can function as a branding tool.

Ultimately, customization breadth is a key differentiator in the market for laser-etched coffee mugs. By offering a wider range of design possibilities, manufacturers can cater to a broader customer base and create products that are both functional and aesthetically appealing. However, challenges such as maintaining design integrity across complex surfaces and ensuring consistent etching quality across varied ceramic materials must be addressed. The ongoing advancements in laser technology are continually expanding the customization breadth, making laser-etched coffee mugs an increasingly versatile and valuable promotional item and personalized gift.

5. Application Versatility

Application versatility, concerning laser-etched coffee mugs, refers to the breadth of contexts in which these customized items can be effectively utilized. This encompasses diverse scenarios ranging from corporate branding initiatives to personal gifting, highlighting the adaptability and wide-ranging utility of the product.

- Corporate Branding and Marketing

Laser-etched coffee mugs serve as effective promotional tools for businesses. They provide a tangible and lasting representation of a company’s brand, suitable for distribution at trade shows, conferences, or as employee appreciation gifts. The mugs offer a practical, everyday item that reinforces brand recognition and fosters a positive association with the company. For example, a technology firm might distribute laser-etched mugs featuring its logo and a company motto to potential clients at an industry event, thereby creating a lasting impression.

- Personalized Gifting and Special Occasions

These mugs offer a personalized gifting option for various special occasions, including birthdays, holidays, and weddings. The ability to engrave names, dates, or custom messages allows for the creation of unique and sentimental gifts that reflect the recipient’s individuality. A common example includes couples receiving laser-etched mugs with their names and wedding date as a memorable keepsake.

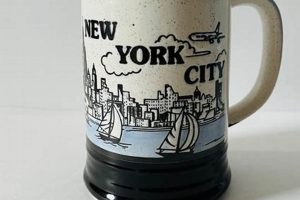

- Souvenirs and Tourism

Laser-etched coffee mugs function as souvenirs for tourists and visitors. Destinations can offer mugs featuring local landmarks, city skylines, or regional artwork, providing a tangible reminder of the travel experience. Museums, historical sites, and tourist attractions often stock these mugs as a readily available and affordable souvenir option.

- Fundraising and Charitable Events

Non-profit organizations and charitable groups utilize laser-etched mugs as fundraising tools. The mugs can be customized with the organization’s logo, mission statement, or artwork created by beneficiaries. Selling these mugs generates revenue while also raising awareness for the organization’s cause. A wildlife conservation organization, for instance, might sell mugs featuring images of endangered species to support its conservation efforts.

The adaptability of laser-etched coffee mugs across these varied applications underscores their inherent versatility. This widespread utility, coupled with the durability and aesthetic appeal of the product, contributes to its enduring popularity as a customizable item suitable for diverse purposes. The ability to tailor the design to specific needs and contexts makes these mugs a valuable asset for organizations and individuals seeking a practical, personalized, and impactful item.

Frequently Asked Questions

The following section addresses common inquiries regarding ceramic drinkware surface-marked with focused light beams. The objective is to provide clear and concise information to aid informed decision-making.

Question 1: What is the expected lifespan of a design on ceramic drinkware marked using focused light beam technology?

The lifespan of such a design depends on several factors, including the etching depth, the quality of the ceramic material, and the frequency of use and cleaning. Generally, properly executed surface marking creates a permanent design that will endure for the functional life of the mug, withstanding regular dishwashing without significant degradation. However, abrasive cleaners may expedite wear.

Question 2: Is there a difference in quality between different providers of ceramic drinkware surface-marked with focused light beams?

Yes. Variations in laser equipment, operator skill, material sourcing, and quality control procedures can significantly impact the final product. Factors such as design precision, etching depth consistency, and ceramic quality may vary substantially between different providers. It is prudent to request samples or review portfolios before committing to a specific vendor.

Question 3: Can all designs be accurately reproduced on ceramic drinkware using focused light beam technology?

While this technology offers considerable design flexibility, certain limitations exist. Extremely intricate designs with fine lines or complex shading may not be perfectly replicated, particularly on curved surfaces. Vector-based graphics generally yield superior results compared to raster images. Consultation with the provider is recommended to assess the feasibility of specific designs.

Question 4: Are ceramic drinkware items surface-marked with focused light beams safe for food and beverage consumption?

Yes, provided that food-safe ceramic materials and appropriate laser equipment are used. The process itself does not introduce any harmful substances to the ceramic. However, it is essential to ensure that the ink or coating, if any, used for filling or coloring the design is also food-safe and compliant with relevant regulations.

Question 5: How does the cost of ceramic drinkware surface-marked with focused light beams compare to other customization methods?

The cost-effectiveness of this method depends on factors such as order volume, design complexity, and material choices. In comparison to screen printing or pad printing, it may be more expensive for large-scale production runs. However, for smaller quantities or designs requiring high precision and durability, it can represent a competitive and worthwhile investment.

Question 6: What are the typical turnaround times for orders of ceramic drinkware surface-marked with focused light beams?

Turnaround times vary depending on the provider’s capacity, order complexity, and current workload. Simple designs and smaller orders may be completed within a few days, while more intricate projects or larger quantities can take several weeks. It is essential to confirm turnaround times with the provider prior to placing an order.

This FAQ section has addressed several fundamental considerations regarding ceramic drinkware utilizing surface marking techniques. It is recommended that prospective customers conduct thorough research and solicit detailed information from potential vendors to ensure optimal results.

The subsequent section will delve into the environmental aspects associated with laser etching processes.

Laser Etched Coffee Mugs

This exploration has detailed the process, benefits, and critical considerations surrounding ceramic drinkware customized through focused light beam technology. Key aspects, including material durability, design precision, etching permanence, customization breadth, and application versatility, have been thoroughly examined. These factors collectively influence the product’s value and suitability for various purposes, ranging from corporate branding to personalized gifting.

The informed selection of this type of customized product necessitates careful evaluation of these elements. While offering durable and aesthetically pleasing personalization, the process demands attention to detail to ensure optimal results. Continued advancements in laser technology promise further enhancements in design complexity and etching precision, solidifying the position of custom-marked ceramic drinkware in both personal and professional contexts. Organizations and individuals are encouraged to thoroughly assess their specific needs and partner with reputable providers to realize the full potential of this customization method.