A specialized appliance designed for high-volume coffee bean processing is essential for businesses such as cafes, restaurants, and coffee roasting facilities. These devices transform whole coffee beans into uniformly ground particles, a critical step in producing quality brewed coffee. The consistent particle size ensures even extraction during brewing, impacting the final flavor profile. For instance, a busy coffee shop relies on its ability to quickly and efficiently produce grounds for hundreds of daily orders.

The utilization of robust grinding equipment provides numerous advantages. Businesses experience increased efficiency, reduced labor costs, and, most importantly, enhanced coffee quality. Historically, manual grinding methods were time-consuming and yielded inconsistent results. The advent of automated grinding technology revolutionized the industry, allowing for precise control over grind size and output volume. This precision is paramount for achieving optimal flavor and aroma extraction, leading to improved customer satisfaction and repeat business.

The subsequent sections will delve into the different types of grinding mechanisms employed, factors influencing the selection of appropriate machinery, and the maintenance procedures necessary for ensuring longevity and consistent performance. Further discussion will explore the significance of grind size in relation to various brewing methods and the evolving technological advancements in this domain.

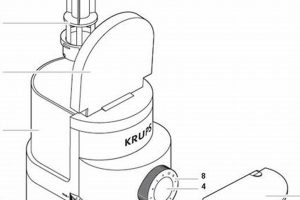

Commercial Coffee Grinder

Proper operation and maintenance of a coffee-grinding apparatus are vital for achieving optimal performance and prolonging equipment lifespan. Adhering to established guidelines minimizes operational downtime and ensures consistent coffee quality.

Tip 1: Grind Size Selection. Employ the correct grind size for the intended brewing method. A coarse grind is appropriate for French press applications, while espresso machines require a fine, consistent grind to facilitate proper extraction.

Tip 2: Regular Cleaning. Implement a daily cleaning schedule to remove coffee oils and grounds from the grinding burrs. Neglecting this task can lead to rancidity and negatively impact flavor profiles.

Tip 3: Burr Inspection and Replacement. Routinely inspect the burrs for wear and tear. Dull burrs produce inconsistent particle sizes, compromising coffee quality. Replace burrs according to manufacturer recommendations or when performance degrades.

Tip 4: Hopper Management. Avoid overfilling the hopper. Excess weight can strain the motor and potentially damage the equipment. Maintain appropriate bean levels to ensure consistent feeding.

Tip 5: Calibrate Grind Settings. Periodically calibrate the grind settings to maintain accuracy. External factors such as humidity and bean density can influence the grinding process. Refer to the equipment manual for calibration procedures.

Tip 6: Avoid Grinding Foreign Objects. Ensure no foreign objects such as stones or metal fragments enter the hopper. These can severely damage the burrs and internal components.

Tip 7: Monitor Motor Temperature. Pay attention to motor temperature during prolonged operation. Overheating can indicate a potential issue and may lead to motor failure. Reduce usage or allow for cooling periods as needed.

Following these guidelines will optimize the functionality of coffee grinding equipment, yielding superior coffee quality, reducing maintenance costs, and maximizing the return on investment.

The subsequent section will address advanced techniques for troubleshooting common issues and explore innovative technologies in coffee grinding.

1. Grind Consistency

Grind consistency, referring to the uniformity of coffee particle size after grinding, is a pivotal attribute in determining the quality and flavor profile of brewed coffee. In the context of a commercial coffee grinding apparatus, achieving optimal grind consistency is not merely a desirable feature but a fundamental requirement for delivering a superior product.

- Extraction Uniformity

Consistent particle size ensures uniform extraction during the brewing process. If the grounds contain a mix of fine and coarse particles, finer particles will over-extract, leading to bitterness, while coarser particles will under-extract, resulting in sourness. Equipment designed for commercial use must deliver grounds that minimize this disparity, allowing for a balanced and nuanced flavor profile. An example of excellent consistency in practice would be using a disc grinder that produces an almost identical size.

- Burr Geometry and Precision

The design and precision of the grinding burrs significantly influence grind consistency. Commercial-grade grinding equipment utilizes advanced burr geometries to ensure that beans are uniformly processed, rather than crushed or shattered. High-precision manufacturing tolerances are critical to prevent particle size variations. For instance, a stepped burr geometry leads to a more even distribution of particle sizes.

- Calibration and Maintenance

Even the best grinding equipment requires periodic calibration and maintenance to maintain optimal grind consistency. Over time, burrs can wear down or become misaligned, leading to increased particle size variation. Regular calibration and burr replacement are necessary to ensure consistent performance. Without it, a grind output with too many fines will be produced, leading to a less than ideal final result.

- Brewing Method Compatibility

Different brewing methods require different grind sizes to optimize extraction. Commercial equipment must be capable of producing a range of grind sizes with a high degree of consistency within each setting. For example, espresso requires a very fine and consistent grind, while French press requires a coarser, more uniform grind. This adaptability ensures that the equipment can meet the diverse needs of a commercial coffee operation. A lower-end grinding machine often does not provide the full range of necessary settings.

The ability of a commercial coffee grinding apparatus to deliver a consistent grind is a primary determinant of its overall value and suitability for professional use. Equipment selection should prioritize models that emphasize precision, durability, and ease of maintenance to ensure consistent performance and customer satisfaction. Achieving consistent results is key to the reputation of the business relying on the equipment.

2. Burr Material

The selection of burr material is a critical factor in the performance and longevity of any coffee grinding apparatus employed in a commercial setting. The material properties directly influence grinding efficiency, heat generation, particle size consistency, and overall lifespan of the equipment.

- Hardness and Durability

The hardness of the burr material dictates its resistance to wear and tear during continuous operation. Harder materials, such as hardened steel or ceramic, exhibit greater durability and require less frequent replacement. This translates to reduced maintenance costs and minimizes downtime in a commercial environment. For example, a high-volume coffee shop grinding several kilograms of beans daily benefits significantly from using grinders with hardened steel burrs due to their enhanced lifespan.

- Heat Conductivity

Grinding coffee beans generates heat due to friction. The thermal conductivity of the burr material impacts the extent to which this heat is dissipated. Materials with lower thermal conductivity retain more heat, which can negatively affect the flavor profile of the ground coffee by causing volatile aromatic compounds to evaporate. Commercial grinders often utilize materials with enhanced heat dissipation properties to mitigate this issue. For instance, some advanced burr designs incorporate cooling fins or are constructed from materials like titanium, known for their superior heat transfer capabilities.

- Material Composition and Flavor Neutrality

The composition of the burr material should be inert to prevent any unwanted flavors from leaching into the coffee grounds. Certain materials, if not properly treated or coated, can impart metallic or other undesirable tastes. Food-grade stainless steel and ceramic are commonly used due to their inherent flavor neutrality and resistance to corrosion. Prioritizing materials that meet stringent food safety standards is essential for maintaining coffee quality and preventing contamination.

- Grinding Efficiency and Particle Size Distribution

The surface properties and geometry of the burr material affect the efficiency of the grinding process and the resulting particle size distribution. Certain materials and surface treatments can enhance the burr’s ability to grip and shear the coffee beans uniformly, leading to a more consistent grind. Precise control over particle size distribution is crucial for optimizing extraction during brewing and achieving the desired flavor characteristics. A burr material which offers fine adjustments leads to the barista having more control over the ground.

The careful consideration of burr material characteristics is paramount in selecting coffee grinding equipment for commercial applications. The choice directly impacts operational costs, coffee quality, and the overall efficiency of the business. Investing in grinders with appropriate burr materials ensures long-term reliability and consistently superior coffee.

3. Motor Power

Motor power, measured typically in watts (W) or horsepower (HP), is a critical specification for equipment designed to grind coffee beans in a commercial setting. The motor’s capacity directly impacts the machine’s ability to consistently and efficiently process large volumes of beans without overheating or experiencing performance degradation. Insufficient power leads to slower grinding speeds, inconsistent particle sizes, and potential motor failure, resulting in operational downtime and compromised coffee quality. A caf consistently serving high volumes of espresso, for example, requires a grinder with a robust motor to maintain workflow during peak hours.

The relationship between motor power and grind quality is also significant. A more powerful motor sustains consistent burr speed under load, ensuring a uniform grind profile, essential for optimal extraction. Lower-powered motors may struggle to maintain consistent speed, particularly when grinding denser or lighter roasted beans, leading to inconsistent extraction and suboptimal flavor. Furthermore, grinders with higher motor power frequently incorporate thermal protection mechanisms to prevent overheating during extended use, contributing to the equipment’s overall durability and reliability. High motor power can give consistent grind to all types of roast.

In summary, motor power is a primary determinant of a grinding machine’s suitability for commercial applications. Selecting equipment with adequate motor power is essential for ensuring consistent performance, maintaining grind quality, and maximizing the longevity of the machine. Failure to consider motor power in relation to the demands of the operation can result in operational inefficiencies, increased maintenance costs, and compromised product quality. It should be a high priority when choosing a grinding machine.

4. Grind Settings

The adjustability of grind settings on a commercial coffee grinder is paramount to its versatility and ability to cater to diverse brewing methods. Grind settings dictate the particle size of the ground coffee, directly influencing extraction rates and the resulting flavor profile. The availability of a wide and precise range of grind settings is a defining characteristic of professional-grade equipment.

- Adaptability to Brewing Methods

Different brewing methods necessitate varying grind sizes for optimal extraction. Espresso, for instance, requires a fine grind to increase surface area exposure and facilitate rapid extraction under pressure. Conversely, French press brewing benefits from a coarser grind to prevent over-extraction and the presence of excessive sediment in the final cup. A commercial coffee grinder with a wide range of grind settings enables businesses to accommodate multiple brewing methods and cater to diverse customer preferences. Restaurants which offer a french press as well as espresso beverages would require this adaptability.

- Consistency and Repeatability

The precision and repeatability of grind settings are crucial for maintaining consistent coffee quality. A professional-grade grinder should allow users to precisely adjust and consistently reproduce specific grind sizes to ensure each batch of coffee is brewed with the same parameters. This consistency minimizes variability and enables businesses to develop and maintain standardized coffee recipes. Some grinders utilize numbered or indexed settings to enhance repeatability, allowing baristas to easily switch between grind sizes and replicate results.

- Impact on Extraction Yield and Flavor

Grind settings directly influence the extraction yield and the flavor characteristics of brewed coffee. Finer grinds increase surface area exposure, leading to higher extraction yields and potentially intensifying bitterness or astringency if over-extracted. Coarser grinds decrease surface area exposure, resulting in lower extraction yields and potentially producing sour or weak-tasting coffee if under-extracted. Adjusting grind settings allows baristas to fine-tune extraction parameters and achieve the desired balance of sweetness, acidity, and body in the final cup. Minor changes to the grinder’s setting makes a difference.

- Calibration and Fine-Tuning

Commercial coffee grinders require periodic calibration and fine-tuning of grind settings to compensate for burr wear, changes in bean density, and variations in humidity. Calibration ensures that the indicated grind settings accurately reflect the actual particle size produced by the grinder. Fine-tuning involves making small adjustments to the grind settings to optimize extraction for specific bean varieties or brewing methods. The best grinders have calibration and fine-tuning settings.

In summation, the adjustability, precision, and consistency of grind settings are critical attributes of a commercial coffee grinder, enabling businesses to adapt to diverse brewing methods, maintain consistent coffee quality, and optimize extraction for specific bean varieties. Equipment selection should prioritize models that offer a wide range of grind settings and allow for precise calibration and fine-tuning to ensure optimal performance and customer satisfaction. Grind settings can greatly impact the customer and their final cup.

5. Hopper Capacity

Hopper capacity, referring to the volume of whole coffee beans a commercial coffee grinder can hold, is a significant determinant of operational efficiency and workflow management. The size of the hopper directly impacts the frequency with which the grinder needs refilling, influencing labor requirements and potentially affecting the consistency of grind production.

- Operational Efficiency

A larger hopper reduces the frequency of refilling, minimizing interruptions during peak service hours. This is particularly crucial in high-volume establishments such as busy cafes or restaurants where consistent workflow is essential. Conversely, smaller hoppers necessitate more frequent refills, increasing labor costs and potentially slowing down service. A coffee shop that experiences high traffic during the morning commute would benefit greatly from a grinder with a large hopper capacity, streamlining operations.

- Bean Freshness and Staling

While larger hoppers offer convenience, they can also negatively impact bean freshness. Coffee beans exposed to air and light for extended periods can stale, losing their aromatic compounds and flavor complexity. In situations where coffee consumption is lower, a smaller hopper might be preferable to ensure that beans are used before significant staling occurs. This highlights the importance of aligning hopper size with the typical consumption rate to optimize coffee quality.

- Grind Consistency and Bean Feed

Hopper capacity can indirectly influence grind consistency. When hoppers are nearly empty, the weight of the remaining beans may not provide consistent pressure for feeding into the burrs, potentially leading to uneven grinding. A hopper that is appropriately sized for the grinding mechanism ensures a consistent and reliable bean feed, contributing to uniform particle size distribution. Moreover, hoppers designed to facilitate smooth bean flow, preventing bridging or clogging, are essential for consistent grinding performance.

- Equipment Size and Space Constraints

Hopper capacity contributes to the overall size of the grinding equipment. In environments with limited counter space, a smaller hopper might be a necessary compromise, even if it requires more frequent refills. Conversely, in larger establishments with ample space, a larger hopper can be accommodated to maximize operational efficiency. Balancing hopper capacity with spatial constraints is a key consideration in selecting appropriate grinding equipment.

The selection of a commercial coffee grinder with the appropriate hopper capacity requires careful consideration of operational demands, bean freshness concerns, grind consistency requirements, and spatial limitations. Balancing these factors ensures optimal performance, minimizes labor costs, and maximizes the quality of the final coffee product. Paying special attention to the capacity is paramount.

6. Maintenance Schedule

A systematically structured maintenance schedule is indispensable for ensuring the sustained functionality, performance consistency, and extended lifespan of any commercial coffee grinder. Neglecting regular maintenance results in diminished grinding efficiency, compromised coffee quality, and potentially costly repairs or premature equipment failure.

- Daily Cleaning Procedures

Daily cleaning protocols are paramount for removing accumulated coffee oils and grounds from the burrs, grinding chamber, and dispensing mechanisms. Failure to adhere to a daily cleaning regimen leads to rancidity, imparting undesirable flavors to the coffee and hindering grinding efficiency. A typical daily cleaning routine includes brushing or vacuuming the burrs and wiping down external surfaces. The implementation of these procedures reduces the risk of flavor contamination and ensures consistent grind quality.

- Burr Inspection and Replacement

Periodic inspection of the grinding burrs is essential for detecting wear, damage, or misalignment. Worn or damaged burrs produce inconsistent particle sizes, resulting in uneven extraction and diminished coffee flavor. Burr replacement should occur according to manufacturer recommendations or when performance degradation becomes evident. A proactive burr inspection and replacement schedule ensures optimal grinding performance and prevents costly equipment failures.

- Motor and Electrical Component Checks

Scheduled inspection of the motor and electrical components is crucial for identifying potential issues such as overheating, loose connections, or frayed wiring. Overheating can lead to motor failure, while loose connections or frayed wiring pose safety hazards. Routine checks should include visual inspection, voltage testing, and cleaning of ventilation openings. Addressing these issues promptly prevents equipment malfunctions and ensures safe operation.

- Calibration and Adjustment

Regular calibration and adjustment of the grind settings are necessary for maintaining accurate particle size control. Over time, external factors such as humidity and bean density can influence the grinding process, requiring adjustments to the grind settings to compensate for these variations. Calibration ensures that the indicated grind settings accurately reflect the actual particle size produced by the grinder. Precise grind settings are required for consistent espresso.

Adherence to a comprehensive maintenance schedule, encompassing daily cleaning, burr inspection and replacement, motor and electrical component checks, and calibration adjustments, is critical for maximizing the performance and lifespan of commercial coffee grinding equipment. This proactive approach minimizes downtime, reduces repair costs, and ensures the consistent delivery of high-quality coffee. An effective maintenance program results in fewer service disruptions.

Frequently Asked Questions

The following questions address common concerns and misconceptions regarding commercial coffee grinding equipment. These answers aim to provide clarity and informed decision-making when selecting and maintaining this essential equipment.

Question 1: What is the expected lifespan of a commercial coffee grinder, and what factors influence it?

The typical lifespan ranges from 5 to 10 years, contingent upon usage frequency, maintenance practices, and the quality of construction. Regular cleaning, proper calibration, and timely replacement of worn parts, such as burrs, significantly extend the operational lifespan.

Question 2: How frequently should the grinding burrs be replaced in a commercial coffee grinder?

Replacement frequency varies depending on the volume of coffee processed and the burr material. As a general guideline, burrs should be replaced after grinding a specific quantity of coffee, usually measured in kilograms or pounds, as specified by the manufacturer. Inspecting the burrs regularly for wear is essential to maintain grind consistency.

Question 3: What are the key differences between flat burr and conical burr commercial coffee grinders?

Flat burr grinders typically produce a more consistent particle size, resulting in a brighter, more defined flavor profile. Conical burr grinders tend to generate a bimodal particle distribution, which can yield a sweeter, more balanced cup. The choice depends on the desired flavor characteristics and brewing methods employed.

Question 4: How important is motor power in a commercial coffee grinder, and what are the potential consequences of insufficient power?

Motor power is critical for maintaining consistent burr speed and throughput, especially during peak service hours. Insufficient power leads to slower grinding speeds, inconsistent particle sizes, and potential motor overheating or failure. Selecting a grinder with adequate motor power is essential for ensuring consistent performance and longevity.

Question 5: What are the common signs of a malfunctioning commercial coffee grinder, and what troubleshooting steps should be taken?

Common signs include inconsistent grind size, unusual noises, overheating, and failure to start. Troubleshooting steps include checking the power supply, inspecting the burrs for damage or obstruction, and verifying the hopper is properly seated. If the issue persists, professional servicing is recommended.

Question 6: How does the type of coffee bean (e.g., light roast vs. dark roast) affect the performance and settings of a commercial coffee grinder?

Darker roasts tend to be more brittle and require coarser grind settings compared to lighter roasts, which are denser and require finer settings. Adjusting the grind settings based on the bean type is crucial for achieving optimal extraction and preventing over- or under-extraction.

Selecting and maintaining commercial coffee grinding equipment requires careful consideration of various factors, including lifespan, burr type, motor power, and maintenance practices. Adhering to these guidelines ensures consistent performance and maximizes the return on investment.

The following section will explore emerging technologies and future trends in commercial coffee grinding.

Commercial Coffee Grinder

The preceding exploration has underscored the critical role of the commercial coffee grinder in delivering consistent, high-quality coffee in professional settings. Discussions have encompassed vital aspects, including grinding mechanisms, burr materials, motor power considerations, the importance of precise grind settings, the impact of hopper capacity, and the necessity of rigorous maintenance schedules. Emphasis has been placed on the interconnectedness of these factors in achieving optimal performance and maximizing equipment lifespan, factors which determine the equipment’s value in the market.

Investing in appropriate grinding apparatus represents a strategic decision for businesses seeking to elevate their coffee offerings and optimize operational efficiency. As technology continues to evolve, ongoing evaluation of equipment advancements and adherence to best practices are paramount. Continued refinement of grinding methodologies promises further enhancements in extraction control, flavor consistency, and operational sustainability within the coffee industry, and will be key for companies to maximize performance and control costs.

![Best Manual vs Electric Coffee Grinder [Guide] Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Best Manual vs Electric Coffee Grinder [Guide] | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://deacoffee.com/wp-content/uploads/2025/06/th-82-300x200.jpg)