This method of producing a chilled coffee concentrate employs precise temperature control and immersion techniques. The process involves sealing coarsely ground coffee and water in a bag, then submerging it in a water bath maintained at a specific, often low, temperature for an extended period. This controlled environment facilitates the extraction of desirable compounds while minimizing the oxidation and bitter notes typically associated with traditional methods.

The advantages of this preparation lie in its ability to produce a consistently smooth and balanced beverage. The lower temperature and controlled environment significantly reduce the acidity and harshness often present in hot-brewed or conventionally steeped cold brew. This results in a smoother, more palatable drink, showcasing the nuanced flavors of the coffee bean. The controlled variables also allow for replicable results, offering a consistent flavor profile across multiple batches. This method represents a technological refinement in the craft of coffee preparation, capitalizing on principles established in modern cooking techniques to enhance the drinking experience.

The subsequent sections will detail the specific equipment required, optimal temperature and time parameters, and techniques for fine-tuning the process to achieve the desired flavor profile. Further discussion will address the storage and usage of the resulting concentrate, along with potential variations and experimental modifications to this innovative brewing approach.

Tips for Enhanced Coffee Preparation

Optimizing the water bath immersion technique for coffee concentrate requires meticulous attention to detail. The following tips are intended to assist in achieving superior results.

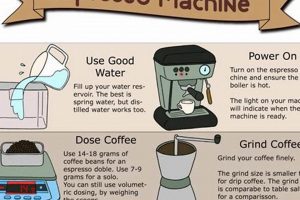

Tip 1: Grind Coarsely and Consistently: A coarse grind is crucial to prevent over-extraction and the resulting bitterness. Aim for a grind size similar to that used for French press brewing. Uniformity in grind size is equally important; a burr grinder is highly recommended over a blade grinder.

Tip 2: Utilize Filtered Water: The water used will directly impact the final flavor profile. Employing filtered water, free of chlorine and other impurities, allows the inherent characteristics of the coffee beans to shine through.

Tip 3: Maintain Precise Temperature Control: Deviation from the target temperature can significantly alter the extraction process. Investing in a quality immersion circulator that maintains consistent temperature is essential for repeatable results. Optimal temperatures generally range between 60-70F (15-21C).

Tip 4: Experiment with Immersion Time: The duration of immersion influences the strength and flavor profile of the concentrate. Starting with a 12-18 hour immersion period is advisable, adjusting as needed based on individual preference. Longer immersion times may lead to a more robust flavor.

Tip 5: Ensure Proper Sealing: Complete sealing of the bag containing the coffee grounds and water is paramount to prevent water from entering and diluting the mixture. A vacuum sealer is ideal for this purpose. If using a zip-top bag, ensure all air is removed before sealing.

Tip 6: Strain Thoroughly: After immersion, strain the concentrate through a fine-mesh sieve or cheesecloth to remove any remaining sediment. Multiple straining passes may be necessary to achieve optimal clarity.

Tip 7: Store Properly: The resulting concentrate should be stored in an airtight container in the refrigerator. Properly stored, the concentrate can maintain its quality for up to two weeks.

These tips, when implemented with diligence, will contribute to a higher quality, more flavorful coffee concentrate. Experimentation and careful record-keeping are encouraged to refine the process to individual tastes.

The subsequent section will explore the potential variations in coffee beans and water ratios to further customize the brewing experience.

1. Temperature Control

Temperature control is paramount in water bath immersion coffee concentrate production, directly influencing the extraction rate of various compounds from the coffee grounds. The precision afforded by this method allows for selective extraction, minimizing undesirable bitter compounds while maximizing the desirable aromatic and flavor components.

- Enzyme Activity Modulation

Lower temperatures, specifically those maintained during this method, inhibit the activity of enzymes that contribute to bitterness and acidity. This results in a smoother, less harsh final product compared to hot brewing or conventional steeping. In hot brewing, elevated temperatures accelerate enzymatic reactions, leading to a more pronounced bitter flavor profile. By contrast, the controlled low temperatures employed in this approach allow for a more balanced and nuanced extraction.

- Extraction Rate Regulation

The rate at which various compounds are extracted from coffee grounds is directly proportional to temperature. By maintaining a consistently low temperature, the extraction process is slowed, allowing for a more controlled and even extraction of flavors. This prevents over-extraction of undesirable compounds, which can occur at higher temperatures. For example, if the temperature is too high, tannins are extracted, leading to an astringent, unpleasant taste.

- Solubility of Compounds

Different compounds within coffee grounds have varying solubility rates depending on temperature. Lower temperatures favor the extraction of certain desirable compounds, such as those responsible for the fruity and floral notes, while limiting the extraction of less desirable compounds that contribute to bitterness. If the temperature were excessively low, however, the extraction of any compound could be insufficient, leaving the final product weak and lacking in flavor. Thus the optimal temperature balances flavor extraction.

- Consistency and Repeatability

Precise temperature control ensures consistency across multiple batches. Fluctuations in temperature can lead to significant variations in flavor profile. The ability to maintain a consistent temperature is crucial for producing a repeatable product with a predictable flavor profile. Unlike traditional methods where temperature is more variable, the immersion circulator provides stability, ensuring that each batch aligns closely with the desired flavor characteristics.

The interconnectedness of these facets underscores the critical role of temperature control in water bath immersion coffee concentrate preparation. The ability to precisely regulate temperature directly influences enzyme activity, extraction rates, compound solubility, and overall consistency, culminating in a superior product characterized by its smoothness, balance, and nuanced flavor profile. Improper temperature control can lead to undesirable flavors and inconsistent results, highlighting the importance of meticulous execution in this brewing method.

2. Extraction Time

Extraction time, a critical variable in water bath immersion coffee concentrate preparation, significantly influences the final flavor profile and characteristics of the beverage. Controlled manipulation of extraction time allows for precise adjustment of strength, body, and overall balance, distinguishing this method from traditional cold brewing techniques.

- Impact on Flavor Profile

Shorter extraction times, typically ranging from 12 to 16 hours, tend to yield a brighter, more acidic concentrate. These shorter durations favor the extraction of volatile aromatic compounds responsible for fruity and floral notes. Conversely, extended extraction times, spanning 18 to 24 hours, result in a bolder, more robust flavor profile, emphasizing chocolate and nutty undertones. Prolonged immersion facilitates the extraction of heavier, less volatile compounds that contribute to body and mouthfeel. The key is balancing the extraction of pleasant and unpleasant compounds. Over-extraction leads to bitterness due to extraction of polyphenols. Under-extraction leads to a weak and sour taste, as the desired flavors have not been developed.

- Influence on Caffeine Content

Caffeine extraction is time-dependent. Longer extraction times generally result in a higher caffeine concentration in the final concentrate. This relationship is not linear; the initial extraction rate of caffeine is faster, gradually slowing down as equilibrium is approached. While temperature influences the rate of caffeine extraction, time remains a primary determinant of the total caffeine content in a water bath immersion preparation. Therefore, the goal is to balance desired flavor and caffeine content for each individual.

- Relationship with Grind Size

Extraction time must be considered in conjunction with grind size. Finer grinds, possessing a larger surface area, extract more quickly. Consequently, shorter extraction times are appropriate for finer grinds, whereas coarser grinds require longer immersion periods to achieve optimal extraction. Adjusting the extraction time based on grind size is crucial for preventing over-extraction and maintaining a balanced flavor profile. Dialing in the grind and the extraction time simultaneously enables precise control over the final concentrate.

- Consistency and Repeatability

Maintaining consistent extraction times is essential for achieving repeatable results. Variations in extraction time, even within a narrow range, can noticeably alter the flavor profile of the concentrate. Utilizing a timer and adhering to a strict brewing schedule is crucial for ensuring consistency across multiple batches. Combined with temperature control, extraction time is a primary driver of consistency.

These facets highlight the interconnectedness of extraction time with other variables in water bath immersion coffee concentrate production. Through careful manipulation of extraction time, in concert with grind size, temperature, and water quality, one can achieve a final product that aligns closely with their desired flavor characteristics. The ability to fine-tune extraction time distinguishes this method as a precise and controlled approach to coffee preparation, yielding a superior and consistently high-quality concentrate.

3. Grind Consistency

Grind consistency plays a crucial role in the efficacy of water bath immersion coffee concentrate preparation. Uniform particle size directly influences the extraction rate and the resulting flavor profile, impacting the overall quality of the final concentrate. Precise control over grind consistency is essential for achieving balanced and predictable results.

- Surface Area and Extraction Rate

Inconsistent grind size leads to varied surface area exposure among coffee particles. Finer particles possess a larger surface area, resulting in faster extraction and potential over-extraction of bitter compounds. Conversely, coarser particles have a smaller surface area, leading to under-extraction and a weak, sour flavor. A uniform grind ensures that all particles extract at a similar rate, promoting a balanced and harmonious flavor profile. Consider a scenario where a blend contains both very fine and very coarse grinds. The fine grinds release bitter notes prematurely, while the coarse grinds fail to contribute sufficient flavor, resulting in a compromised brew. In this controlled immersion environment, consistency is key for optimized flavors.

- Channeling and Uneven Saturation

Inconsistent grind can cause channeling during the water bath immersion process. Smaller particles tend to clump together, creating denser areas that impede water flow. This forces water to bypass these areas, leading to uneven saturation and extraction. The result is a mixture of over-extracted and under-extracted flavors, creating an unbalanced and muddy taste. Even saturation is crucial for maximized flavor extraction from water bath immersion concentrate. For example, imagine if most of the grounds had smaller particle size due to the grinder used; water would have difficulty going through the grounds, leading to limited flavor.

- Sediment and Filtration

Inconsistent grind contributes to increased sediment in the final concentrate. Finer particles are more difficult to filter out, resulting in a cloudy or murky beverage. These fine particles can also contribute to a gritty texture. Consistent grind simplifies the filtration process and results in a cleaner, smoother concentrate. It’s similar to filtering pool water; if it consists of small, medium, and large particles, filter will be clogged sooner.

- Equipment Selection

Achieving consistent grind necessitates the use of a high-quality burr grinder. Burr grinders crush the coffee beans between two revolving abrasive surfaces, producing a more uniform particle size compared to blade grinders, which chop the beans unevenly. Investing in a quality burr grinder is essential for optimal results in water bath immersion coffee concentrate preparation. Inexpensive blade grinders will produce fine and coarse particle sizes, making the filtration and flavor profile quality lower compared to burr grinder.

The interrelationship between grind consistency and each phase of preparation underscores its critical importance. Employing a consistent grind size ensures optimal extraction, minimizes channeling, simplifies filtration, and ultimately contributes to a superior quality, balanced, and flavorful water bath immersion coffee concentrate. The precision afforded by this technique hinges upon careful attention to this fundamental aspect of coffee preparation. While filtration and filtering method helps remove sediment from inconsistent grinds, it still doesn’t eliminate the fact that some ground coffee is over-extracted or under-extracted.

4. Water Quality

The quality of water directly and profoundly impacts the final flavor profile of water bath immersion coffee concentrate. Water acts as the solvent responsible for extracting the soluble compounds from coffee grounds; therefore, its composition significantly influences which compounds are extracted and how they interact. Impurities and minerals present in water can either enhance or detract from the coffee’s inherent characteristics. Hard water, containing high mineral content, may result in a chalky or muted flavor, while heavily chlorinated water can impart an undesirable chemical taste. Conversely, overly soft water may lack the necessary minerals to effectively extract the full range of flavors, leading to a flat or uninteresting cup. The composition of water, therefore, serves as a foundational element in the water bath immersion coffee concentrate process.

The ideal water for this preparation should be clean, odorless, and possess a balanced mineral content. Filtered water, or water specifically formulated for coffee brewing, is highly recommended. Such water typically undergoes treatment to remove chlorine, chloramine, and other impurities that can negatively affect the flavor. Furthermore, the mineral content can be adjusted to optimize the extraction process. For instance, a certain level of magnesium can enhance the extraction of desirable flavor compounds, resulting in a brighter and more nuanced cup. Real-world examples include coffee shops that utilize reverse osmosis systems followed by mineral re-injection to achieve a consistent and high-quality water source, thereby ensuring consistency in their coffee offerings. It allows the cafe and businesses to dial in specific ratios of minerals, improving and extracting targeted flavors.

In conclusion, water quality is not merely a background consideration in water bath immersion coffee concentrate preparation, but an active ingredient that shapes the final product’s taste and aroma. Neglecting water quality can lead to inconsistent and undesirable results, even with the best coffee beans and brewing techniques. By understanding the impact of water composition and utilizing appropriate filtration and mineralization strategies, a brewer can unlock the full potential of their coffee, achieving a consistently superior and flavorful concentrate. Furthermore, the pH in water plays a critical role in extraction of the ground coffee. Therefore, proper assessment and analysis of water is crucial for optimizing results.

5. Filtration Method

The filtration method employed significantly influences the clarity, mouthfeel, and overall perceived quality of water bath immersion coffee concentrate. As this brewing technique extracts soluble compounds over an extended period, it also releases fine particles and oils that, if not adequately removed, can result in a cloudy appearance and a less desirable, often gritty, texture. Therefore, the choice of filtration method is a critical step in refining the final product. Real-world examples include commercial cold brew producers utilizing multi-stage filtration systems, incorporating coarse screens for initial sediment removal followed by finer filters, such as paper or cloth, to capture smaller particles. These systems ensure a consistently clear and smooth concentrate, meeting consumer expectations for visual appeal and palatability. An inadequate filtration method can undermine the benefits of precise temperature control and extended extraction times, highlighting the importance of this component.

Different filtration materials offer varying levels of effectiveness and impact on the flavor profile. Metal filters, such as fine-mesh sieves, are durable and reusable, but they may allow some fine particles and oils to pass through, resulting in a concentrate with a slightly fuller body but potentially reduced clarity. Paper filters, commonly used in drip coffee brewing, offer superior particle retention, producing a clearer and smoother concentrate. However, they can also absorb some of the oils, potentially diminishing the perceived body and richness. Cloth filters, such as cheesecloth or specialized brewing cloths, strike a balance between metal and paper filters, providing good clarity while retaining some of the desirable oils. Choosing the appropriate filtration method requires considering the desired balance between clarity, body, and flavor. For example, one might opt for paper filtration when aiming for a supremely clean and bright flavor profile, while preferring a metal filter when emphasizing a bolder, more robust character. Using a two-step system, such as using a metal filter initially, then paper to remove small particles, is also a viable option for optimized filtration.

In summary, the selection and implementation of an effective filtration method are integral to producing a high-quality water bath immersion coffee concentrate. The filtration method directly affects the concentrates clarity, mouthfeel, and perceived flavor. Choosing the method will also depend on the coffee bean itself. While challenges remain in balancing clarity with the retention of desirable oils, the impact of filtration on the final product is undeniable. The understanding and optimization of this process are essential for consistently delivering a superior coffee experience. Improper filtration can quickly turn an exceptional concentrate into an unpleasant product. Therefore, it is important to evaluate filtering method based on target flavors.

Frequently Asked Questions About Water Bath Immersion Coffee Concentrate

The following addresses common inquiries regarding the water bath immersion method for coffee concentrate preparation, providing detailed explanations to ensure a comprehensive understanding of the process.

Question 1: What distinguishes water bath immersion coffee concentrate from traditional cold brew?

Water bath immersion employs precise temperature control, typically within a narrow range, to optimize extraction and minimize undesirable compounds. Traditional cold brew lacks this temperature regulation, relying solely on ambient temperature steeping, which can lead to inconsistent results.

Question 2: Is specialized equipment required for water bath immersion coffee concentrate?

While not strictly mandatory, an immersion circulator capable of maintaining consistent water temperature is highly recommended for optimal results. A burr grinder is also essential for achieving uniform particle size. Vacuum sealing equipment is also ideal.

Question 3: How does water bath immersion coffee concentrate affect caffeine levels?

Caffeine extraction is influenced by both temperature and time. While water bath immersion typically utilizes lower temperatures, extended steeping times can result in a concentrate with a comparable, or potentially higher, caffeine content than traditional hot brewing methods. Time is a factor to caffeine extraction.

Question 4: What is the ideal ratio of coffee grounds to water for water bath immersion?

A common starting point is a 1:5 to 1:8 ratio of coffee grounds to water. However, the optimal ratio is dependent on the bean’s characteristics and preferred strength, and is best determined via controlled experiments.

Question 5: How long can water bath immersion coffee concentrate be stored?

When stored properly in an airtight container in the refrigerator, water bath immersion coffee concentrate can typically maintain its quality for up to two weeks.

Question 6: Can different coffee bean origins be used with the water bath immersion method?

Yes, water bath immersion is compatible with various coffee bean origins. Each origin will impart a unique flavor profile to the final concentrate, allowing for experimentation and customization. It is important to note that grinding size and extraction time will be specific to the types of coffee bean.

In summary, water bath immersion coffee concentrate preparation offers a controlled and precise method for producing a smooth, balanced, and flavorful coffee concentrate. Attention to detail regarding temperature, grind size, water quality, and filtration is essential for achieving optimal results.

The subsequent section will provide a detailed step-by-step guide to the water bath immersion coffee concentrate process.

Conclusion

This exploration has detailed the nuanced parameters governing the production of sous vide cold brew coffee. Optimal results require precise temperature management, consistent grind size, purified water, and appropriate filtration. Deviations from these controlled variables can result in compromised flavor profiles. This method offers a repeatable and consistent flavor profile. Benefits include a repeatable and consistent flavor profile, and precise and low-temperature extraction which helps improve flavor and cut down bitter notes.

The information provided equips the reader to engage with sous vide cold brew coffee production effectively. Continued refinement through meticulous experimentation will further elevate the quality of this beverage. This process represents a significant advancement in coffee preparation, demanding diligent application of the principles outlined above.